Solar Operations and Maintenance Resources for

After solar energy arrays are installed, they must undergo operations and maintenance (O&M) to function properly and meet energy production targets

Get a quote

Basic Photovoltaic Principles and Methods

Basic Photovoltaic Principles and Me1hods SERI/SP-290-1448 Solar Information Module 6213 Published February 1982 This book presents a nonmathematical explanation of the theory and

Get a quote

What is NOCT (Normal Operating Cell Temperature)?

NOCT (Normal Operating Cell Temperature), is a significant concept in the domain of solar energy and photovoltaic (PV) systems. It refers

Get a quote

Best Practices for Operation and Maintenance of

This work was authored by the National Renewable Energy Laboratory, operated by Alliance for Sustainable Energy, LLC, for the U.S. Department of Energy (DOE) under Contract No. DE

Get a quote

Global perspectives on advancing photovoltaic system

The expression for the power output variation with operating temperature is; (2) P = G T τ p v η r e f A [1 γ r e f (T c 25)] Where GT is the incident global solar radiation, τ p v is the

Get a quote

Italy solar photovoltaic industry

Average price of solar PV modules in Italy 2009-2023 Average price of standard crystalline silicon solar photovoltaic modules in Italy from 2009 to 2023 (in euros per watt)

Get a quote

Best Practices for Operation and Maintenance of

The goal of this guide is to reduce the cost and improve the effectiveness of operations and maintenance (O&M) for photovoltaic (PV) systems and combined PV and energy storage

Get a quote

What Is A Solar Operation And Maintenance Plan?

Solar O&M is a critical part of ensuring that your solar panel system is running smoothly and efficiently. Solar O&M can involve a number of different services, including

Get a quote

Solar Panel Operating Temperature: Complete Guide 2025

Learn how temperature affects solar panel efficiency, optimal operating ranges, and strategies to maximize performance in any climate. Expert guide with real data.

Get a quote

Overview: Tools & Techniques for PV System Operations

Learn about basic solar PV maintenance practices and diagnostic tools. Expert guide covering I-V testing, thermal imaging, preventive maintenance, and troubleshooting techniques.

Get a quote

Solar Manufacturing Cost Analysis | Solar Market

Solar Manufacturing Cost Analysis NREL analyzes manufacturing costs associated with photovoltaic (PV) cell and module technologies and

Get a quote

Photovoltaic Modules Operating Temperature

The operating cell temperatures of photovoltaic (PV) modules directly affect the performance of the PV system. In this study, an effective

Get a quote

Solar PV Module Handling, Storage, Installation

Thank you for choosing Citizen Solar PV modules. This manual contains information regarding handling, storage, installation, operation, maintenance and safety handling of Citizen Solar

Get a quote

Investigating the Effect of Radiative Cooling on the Operating

The reason is that a PV module already has relatively high thermal emissivity, and convective cooling shows a more significant effect than radiative cooling on PV operating

Get a quote

Solar Photovoltaic

Solar photovoltaic (PV) systems are among the most commonly used renewable energy technologies on federal sites. Effective operations and maintenance (O&M) of these systems

Get a quote

Solar PV Module Manufacturing Cost Analysis | Case

Case study on solar PV module manufacturing cost: A comprehensive financial model for the plant''s setup, manufacturing, machinery and operations.

Get a quote

Design and implementation of a photovoltaic I-V curve tracer: Solar

The performance of a photovoltaic (PV) module depends on real operating conditions such as solar irradiance, ambient temperature, and wind speed, in addition to solar

Get a quote

Full Guide to Operations and Maintenance of Solar

In this context, ADNLITE offers a detailed exploration of the operations and maintenance of solar power plants, providing essential insights to effectively

Get a quote

Photovoltaics: Basic Principles and Components

Introduction to PV Technology Single PV cells (also known as "solar cells") are connected electrically to form PV modules, which are the building blocks of PV systems. The module is

Get a quote

Solar Operations and Maintenance Resources for Plant Operators

Conducting regular O&M ensures optimal performance of photovoltaic (PV) systems while minimizing the risks of soiling, micro-cracking, internal corrosion, and other problems. Below,

Get a quote

Solar Operations and Maintenance Resources for

Conducting regular O&M ensures optimal performance of photovoltaic (PV) systems while minimizing the risks of soiling, micro-cracking, internal

Get a quote

Full Guide to Operations and Maintenance of Solar Power Systems

In this context, ADNLITE offers a detailed exploration of the operations and maintenance of solar power plants, providing essential insights to effectively manage and optimize these energy

Get a quote

A simple correlation for the operating temperature of photovoltaic

Following a brief discussion regarding the operating temperature of commercial grade silicon photovoltaic (PV) cells/modules and its effect upon the performance of free

Get a quote

Photovoltaic systems operation and maintenance: A review and

Gaps and future research directions for PV O&M management are proposed. The expansion of photovoltaic systems emphasizes the crucial requirement for effective operations

Get a quote

PRACTICAL OPERATION & MAINTENANCE (O&M)

WARNING: Solar modules remain live during daylight hours, even when the DC isolator is off. Therefore, wiring etc. will still be energised even when the DC isolators are off.

Get a quote

6 FAQs about [Operating solar photovoltaic modules]

What is a solar photovoltaic system?

Solar photovoltaic (PV) systems are among the most commonly used renewable energy technologies on federal sites. Effective operations and maintenance (O&M) of these systems is necessary to maximize system production and help achieve energy reduction and decarbonization goals.

What is a solar PV module?

Solar PV modules – PV modules consist of rigid poly- or monocrystalline or flexible thin film panels. The module collects and converts solar energy to DC electrical energy. Mounting – Mounting equipment secures the PV modules either in a fixed position or to a tracking system.

What is operations and maintenance for optimal photovoltaic system performance?

Operations and Maintenance for Optimal Photovoltaic System Performance is a 5-hour Federal Energy Management Program on-demand training course. This eTraining outlines the necessary steps for directing ongoing or new operation of PV systems for the life of the project across a variety of system types, sizes, and environments.

What are the maintenance strategies for solar PV systems?

In literature, three general maintenance strategies for solar PV systems are mentioned: corrective, preventive, and predictive maintenance. Fig. 8 shows the evolution of maintenance strategies over time, along with examples of maintenance activities for PV systems. Fig. 8. Evolution of maintenance strategies.

What are the most common O&M tasks for solar PV systems?

A majority of solar PV system O&M tasks are visual inspections that don’t require specialty licensed O&M personnel. Personnel need only have knowledge of the proper appearance of electrical wiring and secure mechanical attachments. PV panel soiling (where dust and grime build up on PV panels over time) is the biggest O&M issue for solar PV systems.

What is a solar PV best practice?

The purpose of this Best Practice is to provide an overview of the system components, maintenance requirements, and reporting requirements to keep solar PV systems operating safely and efficiently.

Guess what you want to know

-

Austria solar panels photovoltaic modules solar panels

Austria solar panels photovoltaic modules solar panels

-

Solar Photovoltaic Modules Transparent Solar Panels

Solar Photovoltaic Modules Transparent Solar Panels

-

Advantages of solar photovoltaic black modules

Advantages of solar photovoltaic black modules

-

Singapore solar photovoltaic modules

Singapore solar photovoltaic modules

-

Turkmenistan solar photovoltaic modules

Turkmenistan solar photovoltaic modules

-

Solar panels in Huawei photovoltaic modules

Solar panels in Huawei photovoltaic modules

-

Peruvian solar photovoltaic modules

Peruvian solar photovoltaic modules

-

India flexible solar photovoltaic modules

India flexible solar photovoltaic modules

-

Solar panels and photovoltaic modules

Solar panels and photovoltaic modules

-

Solar photovoltaic modules

Solar photovoltaic modules

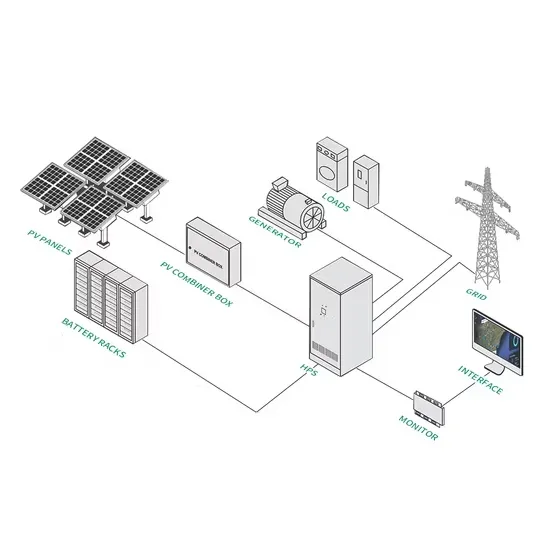

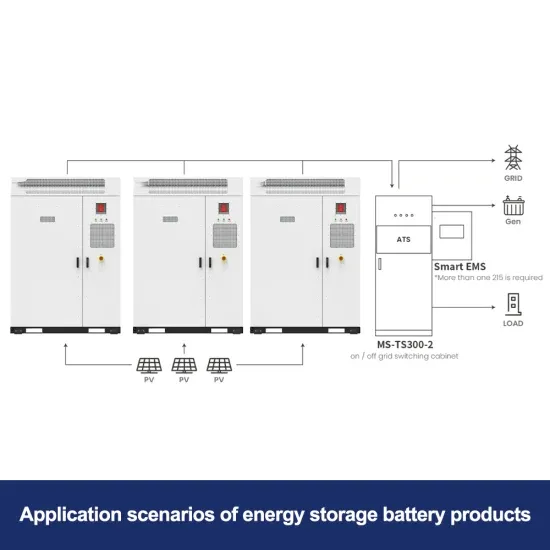

Industrial & Commercial Energy Storage Market Growth

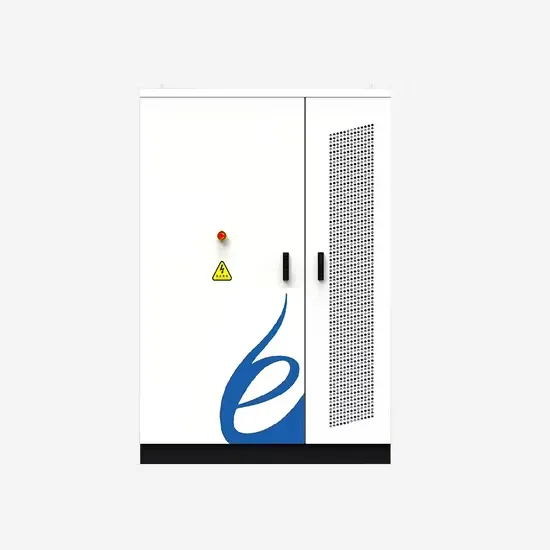

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

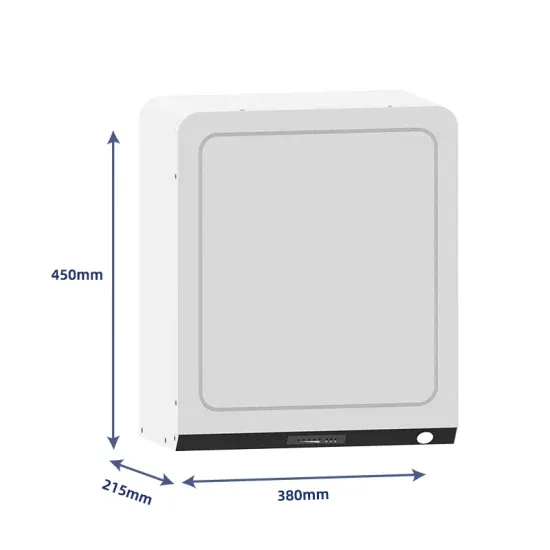

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.