U.S. Energy Storage Industry to Invest $100 Billion in

The energy storage industry is planning to deliver and expand upon these investments and continue the battery manufacturing boom jump-started by rapid energy storage deployment.

Get a quote

Study on the energy consumption of battery cell factories

However, new product and production technologies can optimize battery cell production to achieve savings of up to 66 percent, equivalent to

Get a quote

Manufacturing energy analysis of lithium ion battery pack for

In this paper, we present a detailed manufacturing energy analysis of the lithium ion battery pack using graphite anode and lithium manganese oxides (LMO) cathode, which are

Get a quote

Study on the energy consumption of battery cell factories

However, new product and production technologies can optimize battery cell production to achieve savings of up to 66 percent, equivalent to the energy consumption of

Get a quote

GM and Redwood Materials to pursue use of U.S.-built batteries

In June, Redwood Materials launched Redwood Energy, a new business that deploys both used EV packs and new modules into fast, low-cost energy-storage systems built

Get a quote

Energy use for GWh-scale lithium-ion battery production

Estimates of energy use for lithium-ion (Li-ion) battery cell manufacturing show substantial variation, contributing to disagreements

Get a quote

Energy Storage Manufacturing Analysis

This research raises awareness of potential supply chain barriers, reduces grid demand through energy-saving methods, and better tailors electric vehicle batteries for recycling.

Get a quote

Current and future lithium-ion battery manufacturing

Lithium-ion batteries (LIBs) have been widely used in portable electronics, electric vehicles, and grid storage due to their high energy density, high power density, and long cycle life. Since

Get a quote

U.S. battery storage capacity expected to nearly

The rapid growth of variable solar and wind capacity in states such as California and Texas supports growth in battery storage, which works by

Get a quote

The Future of Energy Storage: Five Key Insights on Battery

Breakthroughs in battery technology are transforming the global energy landscape, fueling the transition to clean energy and reshaping industries from transportation to utilities.

Get a quote

Batteries and Secure Energy Transitions – Analysis

In the power sector, battery storage is the fastest growing clean energy technology on the market. The versatile nature of batteries means they

Get a quote

Energy consumption of current and future production of lithium

New research by Florian Degen and colleagues evaluates the energy consumption of current and future production of lithium-ion and post-lithium-ion batteries.

Get a quote

How Energy-Intensive Are EV Battery Factories?

Cell formation – battery''s first charge cycle – consumes 30% of total energy through controlled electrochemical activation. Material refinement for NMC811 cathodes demands 15kWh/kg of

Get a quote

How does the energy consumption during the production of

Lithium-ion battery factories consume roughly 30 to 65 kWh of electricity per kWh of battery capacity produced, with some recent studies indicating values around 30–35

Get a quote

SUNC Energy Storage System: All-in-one ESS inverter battery

SUNC Energy Storage System: All-in-one ESS inverter battery, 5-30kwh battery capacity, can be charged by solar panels and electricity, WiFi module connects to phone check system

Get a quote

Energy used to Manufacture a Cell

Romare and Dahllöf [3] conclude with a larger number and bigger range for cell manufacturing energy requirement of 97 to 180kWh/kWh. Simon Davidsson Kurland [2] has

Get a quote

Manufacturing energy analysis of lithium ion battery pack for electric

In this paper, we present a detailed manufacturing energy analysis of the lithium ion battery pack using graphite anode and lithium manganese oxides (LMO) cathode, which are

Get a quote

Battery energy storage systems | BESS

A Battery Energy Storage System (BESS) is a technology-based solution that stores electrical energy using rechargeable batteries for later use. These

Get a quote

Energy Storage & Conversion Manufacturing

To establish public-private partnerships that address manufacturing challenges for advanced battery materials and devices, with a focus on de-risking, scaling, and accelerating adoption of

Get a quote

Battery Energy Storage Systems Report

This information was prepared as an account of work sponsored by an agency of the U.S. Government. Neither the U.S. Government nor any agency thereof, nor any of their

Get a quote

Charted: Battery Capacity by Country (2024-2030)

According to the International Energy Agency, in 2024, electric vehicle sales rose by 25% to 17 million, pushing annual battery demand past 1

Get a quote

Reducing the energy consumption of battery cell gigafactories

As the adoption of electric vehicles (EVs) and the demand for stationary storage and other energy applications continue to accelerate, the need for battery cells is rising sharply. Producing these

Get a quote

Breaking It Down: Next-Generation Batteries

With electric vehicles (EVs) that get us places, cell phones that connect us to others, and utility-scale electric grid storage that powers our homes, batteries

Get a quote

Energy Storage | Energy Systems Integration Facility

At the ESIF, diverse energy storage capabilities enable researchers to study and improve the state of the art in storage technologies,

Get a quote

Energy use for GWh-scale lithium-ion battery production

Estimates of energy use for lithium-ion (Li-ion) battery cell manufacturing show substantial variation, contributing to disagreements regarding the environmental benefits of

Get a quote

6 FAQs about [Electricity consumption in manufacturing energy storage batteries]

How much energy does a battery use?

When compared, the industrial scale battery manufacturing can reach an energy consumption as low as 14 kWh/kg battery pack, representing a 72% decrease in the energy consumption, mainly from the improved efficiency relative to the increased production scale.

How much energy does a battery manufacturing facility use?

Dai et al (2019) estimate the energy use in battery manufacturing facilities in China with an annual manufacturing capacity of around 2 GWh c to 170 MJ (47 kWh) per kWh c, of which 140 MJ is used in the form of steam and 30 MJ as electricity. Ellingsen et al (2015) studied electricity use in a manufacturing facility over 18 months.

Can a new battery cell production technology save energy?

However, new product and production technologies can optimize battery cell production to achieve savings of up to 66 percent, equivalent to the energy consumption of Belgium or Finland (in 2021). These groundbreaking results have now been published in the world-renowned journal “Nature Energy”.

How will energy consumption of battery cell production develop after 2030?

A comprehensive comparison of existing and future cell chemistries is currently lacking in the literature. Consequently, how energy consumption of battery cell production will develop, especially after 2030, but currently it is still unknown how this can be decreased by improving the cell chemistries and the production process.

How will battery technology affect energy consumption?

Fourth, owing to large investments in battery production infrastructure, research and development, the resulting technology improvements and techno-economic effects promise a reduction in energy consumption per produced cell energy by two-thirds until 2040, compared with the present technology and know-how level.

How much energy does a battery pack consume?

The specific energy consumption of compressed air is set at 4 cfm/hp, and an average power factor of 0.85 is used in calculating the electricity energy consumption. After the battery cells manufactured, the manual assembly of the battery pack consumes 3.9 Wh/kg energy for welding and screwing . 3.1.

Guess what you want to know

-

Does it require energy storage batteries to connect surplus electricity to the grid

Does it require energy storage batteries to connect surplus electricity to the grid

-

Energy storage battery yield rate on the electricity consumption side

Energy storage battery yield rate on the electricity consumption side

-

Total electricity consumption of battery energy storage in France

Total electricity consumption of battery energy storage in France

-

Batteries and Energy Storage Batteries

Batteries and Energy Storage Batteries

-

How many types of batteries are there in energy storage cabinets

How many types of batteries are there in energy storage cabinets

-

Cost-effectiveness of Dutch industrial and commercial energy storage batteries

Cost-effectiveness of Dutch industrial and commercial energy storage batteries

-

Energy storage batteries on containers

Energy storage batteries on containers

-

Where are the batteries for the energy storage cabinets manufactured

Where are the batteries for the energy storage cabinets manufactured

-

How to get cheap batteries for energy storage cabinets

How to get cheap batteries for energy storage cabinets

-

Cost of home energy storage batteries in Ethiopia

Cost of home energy storage batteries in Ethiopia

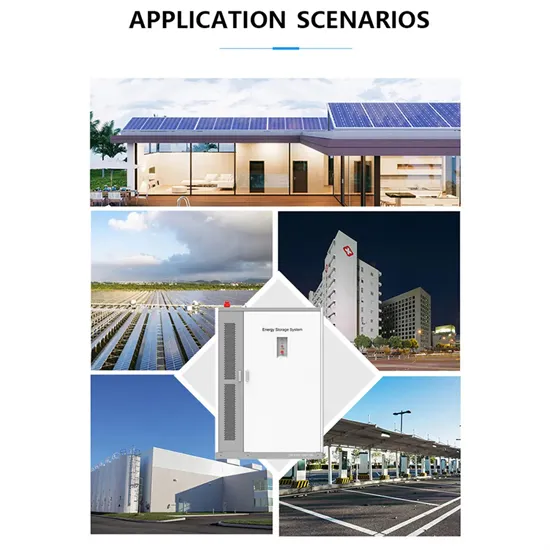

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

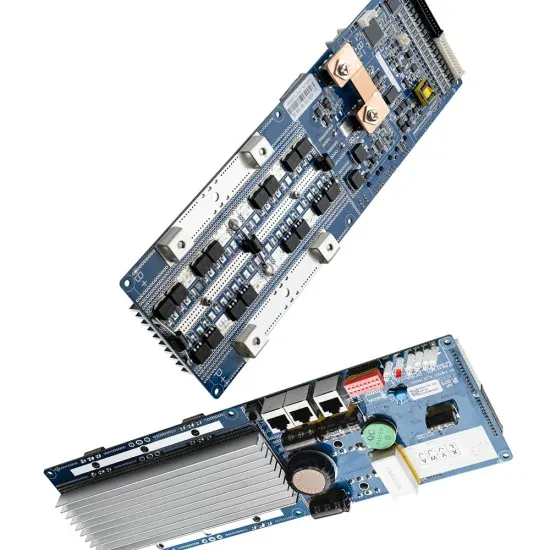

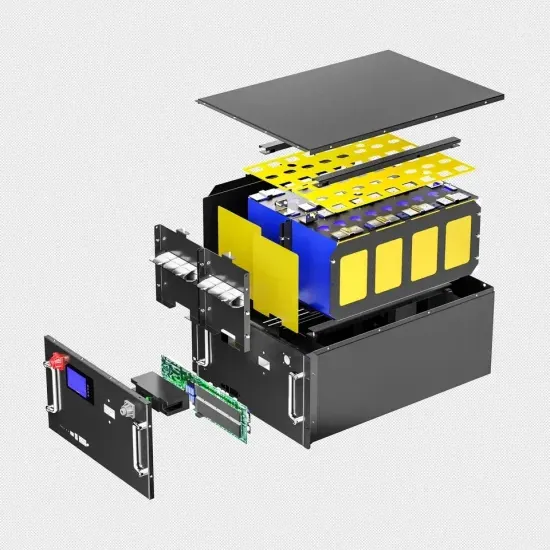

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.