The Power of Submarine Energy: Generating Electricity Beneath

Whether through nuclear reactors, conventional engines, or energy storage units, each component of submarine power generation systems contributes to the seamless

Get a quote

New Microgrid Provides Resilience to U.S. Navy Submarine Base

Recent energy conservation measures include upgrades to modernize the base''s electrical infrastructure and steam distribution systems, conversion to LED lighting and the

Get a quote

Submarine power plants: potential of new

For fuel cell-powered submarines, the prospects are currently slightly lower; up to 5500 nautical miles. There is one important factor to take

Get a quote

Power Supply

To supply this power, submarines are equipped with diesel engines that burn fuel and/or nuclear reactors that use nuclear fission. Submarines also have batteries to supply electrical power.

Get a quote

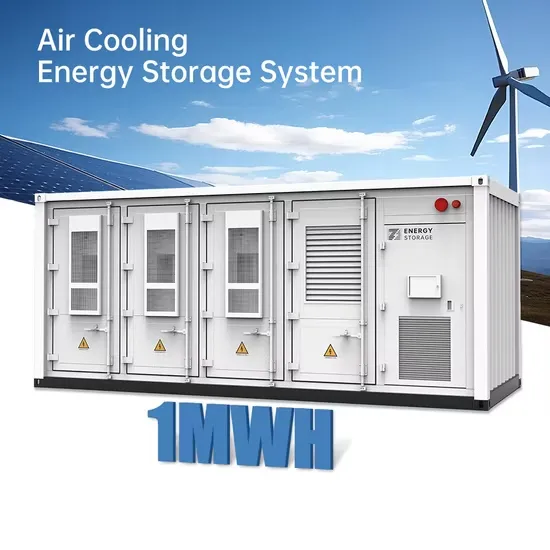

Cooling types for off-grid base station applications.

In order to ensure the safety of fluid flow in deep-water submarine pipelines, a safe and energy-saving built-in skin effect electric heat tracing technology was

Get a quote

Submarine power plants: potential of new configurations |SWZ

Both lithium-ion batteries and fuel cells increase the submerged energy storage capacity, enabling submarines to sail submerged for longer periods of time. This is considered

Get a quote

Submarine communication in the Navy – USAMM

The U.S. Navy''s submarine communication system is a critical part of America''s national security in that it allows the submarine fleet to remain at

Get a quote

Design studies into the potential of novel submarine power plant

Both lithium-ion batteries and fuel cells increase the submerged energy storage capacity, enabling submarines to sail submerged for longer periods of time. This is considered

Get a quote

United States Navy submarine bases

Submarine bases are military bases that offer good fleet anchorage and are designed to refuel and resupply submarines. The peak number of US submarine bases was during World War II,

Get a quote

How do nuclear-powered submarines work? A nuclear

Nuclear submarines are powered by a miniature onboard fission reactor. They can go for decades without refuelling, making them faster,

Get a quote

Submarine Reactors

Russian submarines have 100''s of MW. With an enrichment level of 93-97%, modern naval reactors have a 20 to 30-year lifetime, with refueling every 10 years. New submarine reactor

Get a quote

United States Navy submarine bases

The United States Navy built permanent and temporary submarine bases around the world to maintain its fleet of submarines and serve the needs of the crews. Submarine bases are military bases that offer good fleet anchorage and are designed to refuel and resupply submarines. The peak number of US submarine bases was during World War II, as the submarine was well suited for fighting i

Get a quote

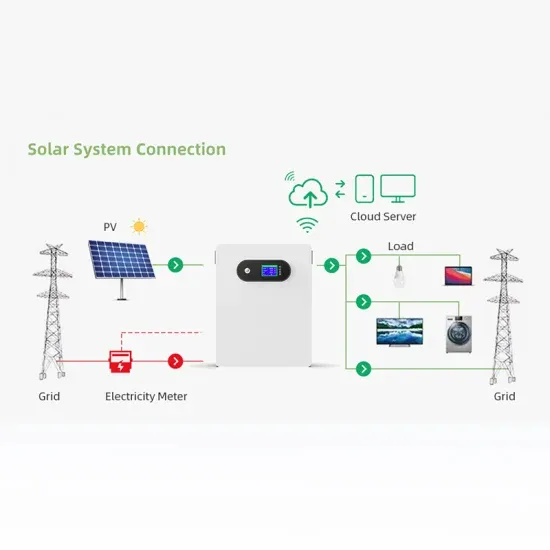

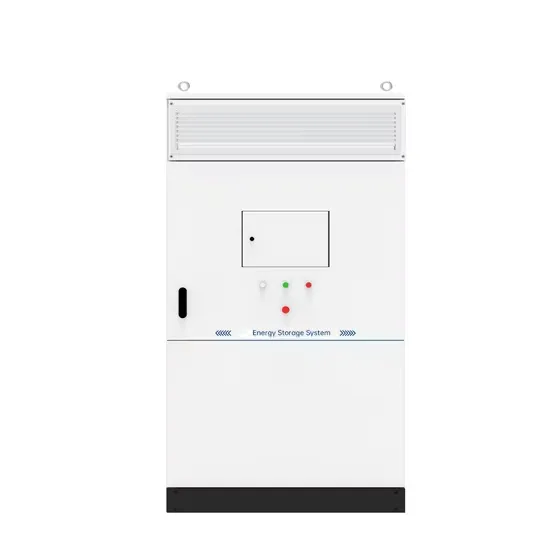

What types of energy storage stations are there?

Energy storage stations can be categorized into various types based on their technologies and applications. 1. There are multiple primary

Get a quote

3 Underwater Vehicle Charging

There are few viable options for powering an underwater vehicle recharge station other than marine energy (see Figure 3.10). Hydrogen-oxygen fuel cells are emerging as a viable

Get a quote

Design studies into the potential of novel submarine

For example, the German Type 212A submarines use a fuel cell system for air independent power supply and Japanse Taigei class

Get a quote

19 Different Types of Submarines Explained (With

Plunge into the depths of marine engineering! Discover 19 unique submarine types with photos, from military giants to research subs and

Get a quote

Submarine Base Powers Up Its Own Microgrid | CT

Captain Ken Curtin, who is the 53rd Commanding Officer of the submarine base, said energy, in all its forms, is critical to ensuring the success

Get a quote

Subsea power turbines may offer new offshore renewable energy

Subsea or tidal power turbines may be the next big technology in offshore renewable energy, and research and development efforts are underway on several fronts.

Get a quote

Types of Sonar Systems Used by Navies around the World

Learn about the different sonar systems used by navies globally, including active, passive, and advanced technologies for naval defense and underwater operations.

Get a quote

Floating offshore substation model test shows potential

The energy transition is a hot topic within the offshore industry nowadays, and for good reason. Effects of climate change are imminent and it is necessary to invest in the

Get a quote

New Microgrid Provides Resilience to U.S. Navy

Recent energy conservation measures include upgrades to modernize the base''s electrical infrastructure and steam distribution systems,

Get a quote

How does a submarine nuclear power plant work

A submarine nuclear power plant, often referred to as a nuclear propulsion system, operates on principles similar to those of a land-based nuclear power

Get a quote

How does a submarine nuclear power plant work

A submarine nuclear power plant, often referred to as a nuclear propulsion system, operates on principles similar to those of a land-based nuclear power plant. However, its primary purpose

Get a quote

Evolution of Modern Submarine Power Plants – Pt. I

From the advent of submarine design, a crucial obstacle was the ability to provide life support for the crews and later-on combustion air for propulsion engines, hence, early submarines ran

Get a quote

6 FAQs about [What types of submarine energy base stations are there]

Why do submarines use lithium-ion batteries and fuel cells?

Both lithium-ion batteries and fuel cells increase the submerged energy storage capacity, enabling submarines to sail submerged for longer periods of time. This is considered a large operational advantage for submarines. Both technologies are also already applied in actual operational submarines.

What is a submarine nuclear power plant?

A submarine nuclear power plant, often referred to as a nuclear propulsion system, operates on principles similar to those of a land-based nuclear power plant. However, its primary purpose is to provide propulsion for submarines rather than generating electricity for a public grid. Here’s a breakdown of how this sophisticated system works:

What is a submarine base?

Submarine bases are military bases that offer good fleet anchorage and are designed to refuel and resupply submarines. The peak number of US submarine bases was during World War II, as the submarine was well suited for fighting in the vast Pacific War, often in enemy waters. Many of the United States submarine bases were closed after the war.

What are the power plant options for non-nuclear submarines?

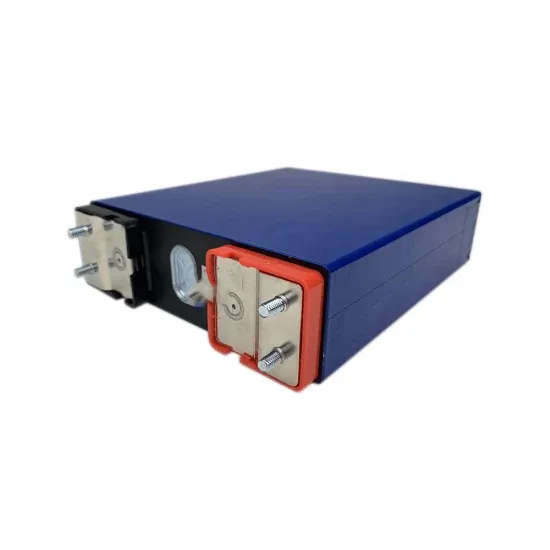

With the new emerging technologies, the amount of power plant options for non-nuclear submarines is increasing, especially for the submerged power supply. Fuel cell technology enables an air independent power supply, operating on pure hydrogen and pure oxygen. Lithium-ion batteries can be used as an alternative for the lead-acid batteries.

Do Submarines need electricity?

Submarines also need electric power to operate the equipment on board. To supply this power, submarines are equipped with diesel engines that burn fuel and/or nuclear reactors that use nuclear fission. Submarines also have batteries to supply electrical power.

Which power plant configuration is best for a submarine?

With the use of the Mean Value First Principle submarine power plant model, multiple powerplant configurations can be compared with each other based on required mass and volume. Both mass and volume are critical design parameters for a submarine. Therefore, the power plant configuration with the lowest mass and volume is preferable.

Guess what you want to know

-

What are the hybrid energy mobile 5G base stations

What are the hybrid energy mobile 5G base stations

-

What are the energy storage cabinets for Sierra Leone communication base stations

What are the energy storage cabinets for Sierra Leone communication base stations

-

What types of wind power are there for cross-border communication base stations

What types of wind power are there for cross-border communication base stations

-

What are the hybrid energy generation methods for Bulgarian communication base stations

What are the hybrid energy generation methods for Bulgarian communication base stations

-

What are the hybrid energy distribution systems for communication base stations

What are the hybrid energy distribution systems for communication base stations

-

What is the energy storage battery for communication base stations

What is the energy storage battery for communication base stations

-

What are India s modern energy storage power stations

What are India s modern energy storage power stations

-

What equipment does the energy storage system of a mobile communication base station have

What equipment does the energy storage system of a mobile communication base station have

-

Investment in solar energy projects for communication base stations

Investment in solar energy projects for communication base stations

-

What is the load of the base station energy management system in kw

What is the load of the base station energy management system in kw

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.