Solar panel types and differences: monocrystalline

The main types of solar panels on the market today are monocrystalline silicon, polycrystalline silicon and amorphous silicon solar cells. Differences between

Get a quote

Top 10 Flexible Thin Film Solar Panel Brands in the USA 2022

The flexible solar panel industry is growing fast in the USA due to consumers'' demand for this type of solar panel for camping, boating, and other outdoor activities.

Get a quote

[Comparison] Monocrystalline vs Polycrystalline Solar

[Chart] This monocrystalline vs polycrystalline solar panels guide will discuss the pros and cons of these conventional but prevalent panels.

Get a quote

Top 5 American Solar Panel Manufacturers In 2025

Top 5 American solar panel manufacturers in 2025: A list of top U.S. solar panel manufacturers. Find the best companies that produce high-quality, American-made solar

Get a quote

Top 8 Thin Film Solar Panel Manufacturers & Factories

In this article, we will explore the top 8 manufacturers of thin film solar panels, who have demonstrated excellence in their locations, product ranges, and technological advancements.

Get a quote

Top 8 Thin Film Solar Panel Manufacturers & Factories

In this article, we will explore the top 8 manufacturers of thin film solar panels, who have demonstrated excellence in their locations, product ranges, and

Get a quote

Thin-Film Photovoltaic Cell Manufacturers in the United States

Konarka manufactures Power Plastic, a thin, flexible, organic solar panel that other business manufacturers build into their products. Our unique solar technology is effective in indirect

Get a quote

SoloPower® | Thin-Film Photovoltaic (PV) Manufacturer

Our powerful line of SoloPower™ thin film solar modules combines our proprietary photovoltaic technology with stringent testing protocols, ease of installation and proven real

Get a quote

Thin-Film Photovoltaic Companies

Major players in the thin-film photovoltaic market include First Solar (US), KANEKA CORPORATION (Japan), Oxford Photovoltaics Ltd. (UK), Ascent Solar Technologies, Inc.

Get a quote

Top 10 Flexible Thin Film Solar Panel Brands in the

The flexible solar panel industry is growing fast in the USA due to consumers'' demand for this type of solar panel for camping, boating, and

Get a quote

Amorphous solar panels: What you need to know

As the solar industry continues to grow, so do its product offerings. Various alternative solar panel technologies offer some unique advantages

Get a quote

Who benefits most from manufacturer tax credits in IRA, thin-film

A crystalline silicon solar panel first starts as metal-grade silicon. A company purifies that into solar-grade polysilicon. Then it is shaped into ingots, which are cut into silicon

Get a quote

Polysilicon Market Size & Share | Forecast Analysis,

Based on application, the polysilicon market is segmented as photovoltaic solar cells {monocrystalline solar cells, multi- crystalline solar cells, thin-film solar

Get a quote

Thin Film Photovoltaic Market Size, Industry Share | Forecast

A thin-film solar cell or photovoltaic (PV) cell is a device to produce electrical energy by using light or solar energy. It is made of different layers mounted on a substrate to provide efficient

Get a quote

Thin Film Photovoltaics Market Size, Share

Thin film photovoltaics market size was valued over USD 7.14 billion in 2023 and is estimated to grow at a CAGR of over 16.5% between 2024 and 2032, driven

Get a quote

Solar Manufacturing Market Size, Share, Growth | Industry

Polysilicon provides a more economical alternative with a little low efficiency, making it popular for a large -scale farm. Thin film technology, including the CDTE and the Cigs panel, is mild and

Get a quote

The current state of U.S. polysilicon production – pv magazine

German-headquartered Wacker Chemie and Hemlock Semiconductor are currently the only two U.S. producers of solar-grade polysilicon. Wacker has a site in

Get a quote

Top 10 Thin film solar cell manufacturers in the World 2025

Product Details: This document details various flexible thin-film solar panels from different manufacturers in the USA, including SunPower, PowerFilm, Ascent Solar Technologies,

Get a quote

EU Solar Manufacturing Map

The EU Solar Manufacturing map gives an overview of solar manufacturing companies active along the solar PV chain. On this map, you''ll find manufacturers spanning from polysilicon to

Get a quote

6 FAQs about [Thin-film polysilicon photovoltaic panel manufacturers]

Who makes thin film solar panels?

Companies involved in thin film panel production. 118 thin film panel manufacturers are listed below. Amorphous, CIS Family, CdTe, Fle... Amorphous, CIS Family, CdTe, Fle... Amorphous, CIS Family, CdTe, Fle... List of Thin-Film solar panel manufacturers.

Who makes portable solar panels?

In association with the California-based Merlin Solar, 4thD Solar manufactures portable solar panels. The prototypes of portable solar panels XP160 and XP80 were made testing for nearly six months. Based on performance, these portal solar panels are among the best in the market, especially for outdoor use.

Will US solar-grade polysilicon production keep pace with domestic PV supply chain?

Despite rising tariffs on imports and a looming U.S. Department of Commerce investigation, American solar-grade polysilicon production is expected to keep pace with the growth of the domestic PV supply chain. From pv magazine 03/25 U.S. solar module manufacturing has grown fivefold since supportive legislation passed in 2022.

What makes PowerFilm unique?

PowerFilm’s proprietary manufacturing provides custom amorphous silicon panels that work in any light environment, including the indoor, industrial lighting of many IoT sensor applications. Celebrating over thirty years in business, PowerFilm is proud to be one of the few US-based solar manufacturing companies operating today.

Will US polysilicon production increase as demand grows?

Polysilicon facilities in the United States may also be able to increase their production capacity as demand grows. “If you call the U.S. a 40 GW to 50 GW market, and account for 20 GW [of non-silicon based] thin-film [solar modules], we have plenty of western poly to cover U.S. wafer/cell production.” Tariffs

How much polysilicon is needed per gigawatt of PV module capacity?

The research firm noted that polysilicon consumption per gigawatt of PV module capacity in 2023 was only a quarter of what was needed per gigawatt in 2006. Polysilicon facilities in the United States may also be able to increase their production capacity as demand grows.

Guess what you want to know

-

High-efficiency thin-film photovoltaic panel manufacturers

High-efficiency thin-film photovoltaic panel manufacturers

-

Indonesia s new photovoltaic panel manufacturers

Indonesia s new photovoltaic panel manufacturers

-

The five major manufacturers in the photovoltaic panel market

The five major manufacturers in the photovoltaic panel market

-

West African photovoltaic panel manufacturers prices

West African photovoltaic panel manufacturers prices

-

Nicaragua 100W photovoltaic panel manufacturers

Nicaragua 100W photovoltaic panel manufacturers

-

Photovoltaic panel pressure supporting manufacturers

Photovoltaic panel pressure supporting manufacturers

-

Kuwait photovoltaic panel manufacturers

Kuwait photovoltaic panel manufacturers

-

Top 10 photovoltaic panel manufacturers in Swaziland

Top 10 photovoltaic panel manufacturers in Swaziland

-

Are there any photovoltaic panel manufacturers in Vanuatu

Are there any photovoltaic panel manufacturers in Vanuatu

-

Brazilian photovoltaic panel equipment manufacturers

Brazilian photovoltaic panel equipment manufacturers

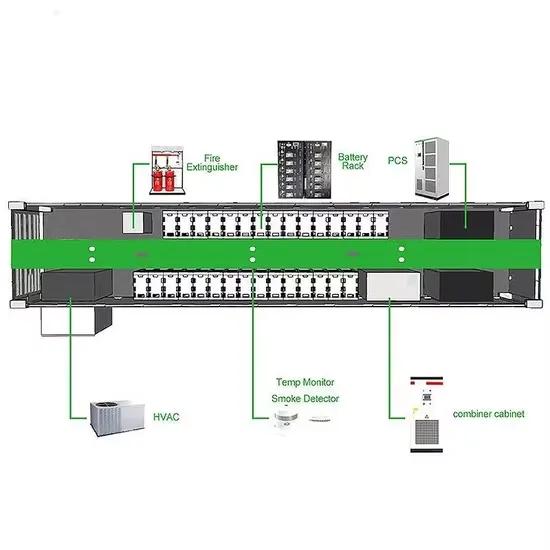

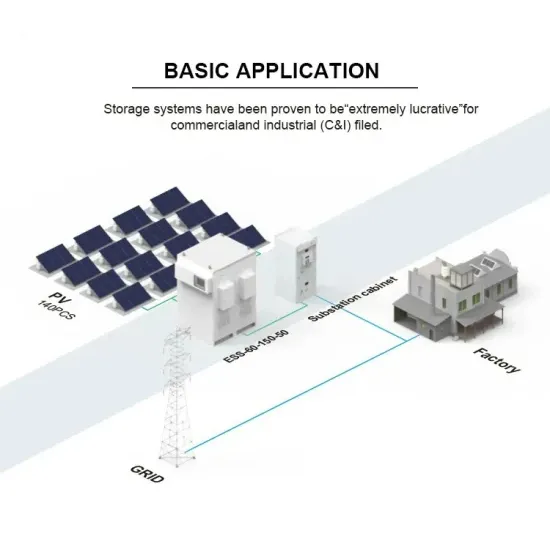

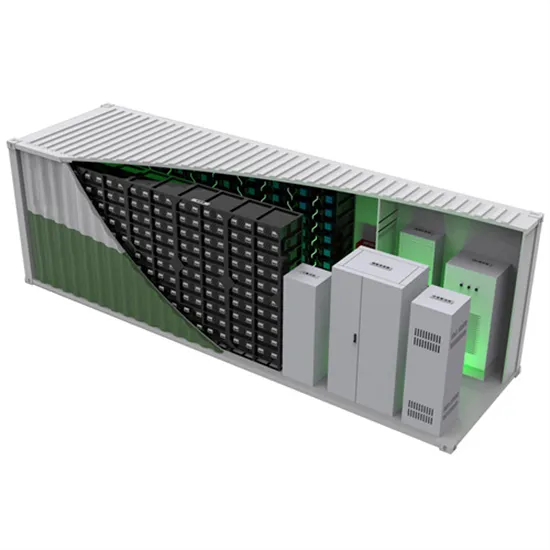

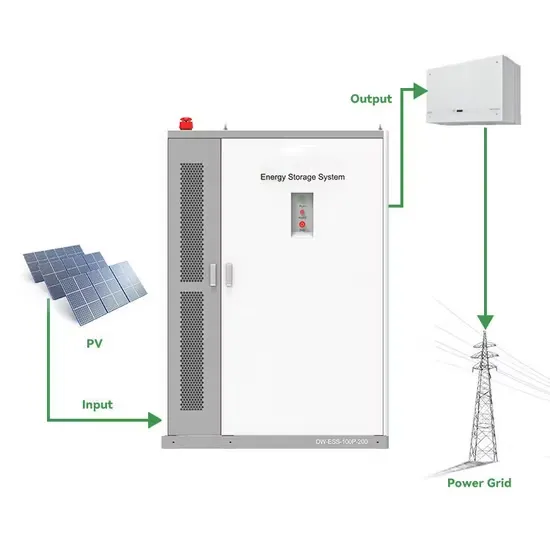

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.