IEA_batt_000310.PDF

Characteristic of the open (or vented) lead acid battery is that the small amounts of hydrogen and oxygen produced at the electrodes during battery operation can be vented to the atmosphere

Get a quote

Battery Charging Station Optimization

Knowing how important this is, we will walk you through some of the key factors that are involved in setting up your forklift battery charge station ideal for lead-acid industrial batteries.

Get a quote

Tips For Setting Up a Safe Battery Charging Station

How and where you charge lead-acid forklift batteries is critical for efficient and secure operations. The following is an overview of design tips from the Apex experts to help you understand the

Get a quote

Battery Box

It is a compliant, safe and environmentally responsible storage and transportation system for used lead acid batteries. The Metal Recovery Industries'' BTS Box delivers maximum safety while

Get a quote

1926.441

Batteries of the unsealed type shall be located in enclosures with outside vents or in well ventilated rooms and shall be arranged so as to prevent the escape of fumes, gases, or

Get a quote

Lead Acid Battery

Construction of Lead Acid Battery The various parts of the lead acid battery are shown below. The container and the plates are the main part of the lead acid battery. The container stores

Get a quote

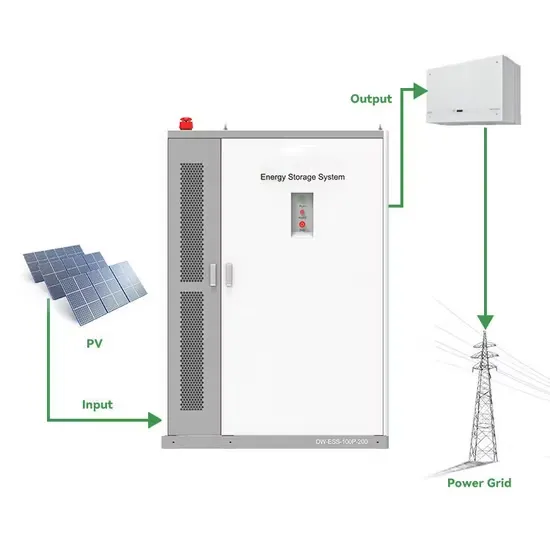

Battery energy storage system

A battery energy storage system (BESS), battery storage power station, battery energy grid storage (BEGS) or battery grid storage is a type of energy storage

Get a quote

What is Lead Acid Battery? Construction, Working,

The battery which uses sponge lead and lead peroxide for the conversion of the chemical energy into electrical power, such type of battery is called a lead acid

Get a quote

Battery Room Ventilation Information | BHS

Lead acid motive power batteries produce hydrogen gas and other fumes at 80% recharge point, making proper ventilation in the battery charging area extremely important. Hydrogen gas is

Get a quote

Understanding OSHA''s Battery Room Ventilation Requirements

Prevent sparks, flames and electrical arcs in the battery charging room to minimize danger, and post no smoking signs. Never handle a lift truck battery if the battery room''s

Get a quote

Ventilation of battery charging rooms for lead traction

Doors and windows are only considered to be appropriate air inlet and outlet opening if it is ensured that are constantly open during the charging process and the necessary cross-section

Get a quote

Gas Detection for Battery Charging Stations | CETCI

Gas Detection for Battery Charging Stations Continuous monitoring of hydrogen gas at lead acid battery charging stations Equipment powered by lead acid

Get a quote

Battery charging station for industrial trucks

Battery charging stations are necessary to charge electric powered industrial trucks with lead-acid battery. They must meet certain requirements associated

Get a quote

Battery charging station for industrial trucks

Battery charging stations are necessary to charge electric powered industrial trucks with lead-acid battery. They must meet certain requirements associated with the handling of lead-acid.

Get a quote

Lead Acid Battery Container

Prevent sparks, flames and electrical arcs in the battery charging room to minimize danger, and post no smoking signs. Never handle a lift truck battery if the battery room''s

Get a quote

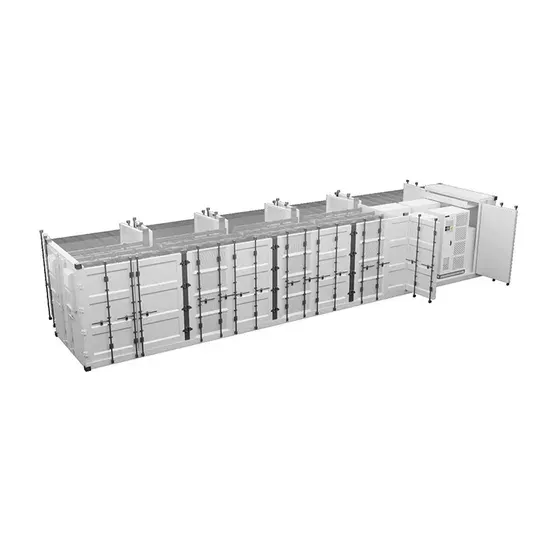

Lead-Acid Battery Energy Storage Containers: Powering the

Lead-acid battery energy storage containers aren''t exactly dinner table talk—yet. But with industries shifting toward sustainability, these rugged workhorses are stealing the

Get a quote

Lead Acid Battery Container

The BTS Container is designed for used lead acid batteries to be collected from the "coal face", the Used Battery Generators, and be delivered directly to the Battery Recycling Facilities,

Get a quote

Battery Room Ventilation and Safety

It is common knowledge that lead-acid batteries release hydrogen gas that can be potentially explosive. The battery rooms must be adequately ventilated to prohibit the build-up of

Get a quote

White Paper | The Proper Charging of Stationary Lead-Acid

Optimize battery life with proper charging techniques. Learn about lead-acid battery maintenance, charging methods, and voltage control in this technical guide.

Get a quote

Tips For Setting Up a Safe Battery Charging Station

How and where you charge lead-acid forklift batteries is critical for efficient and secure operations. The following is an overview of design tips from the Apex

Get a quote

Understanding OSHA''s Battery Room Ventilation Requirements

The Occupational Safety and Health Administration (OSHA)''s regulations for forklift battery charging and maintenance outline strict requirements that each battery room be

Get a quote

6 FAQs about [Lead-acid battery charging container base station]

Do lead-acid batteries release hydrogen gas?

It is common knowledge that lead-acid batteries release hydrogen gas that can be potentially explosive. The battery rooms must be adequately ventilated to prohibit the build-up of hydrogen gas. During normal operations, off gassing of the batteries is relatively small.

Are battery charging rooms based on lead traction batteries safe?

battery charging rooms for lead traction batteries 1. ForewordIn order to avoid explosion hazards sufficient ventilation of charging rooms for traction batteries based on lead battery technology is mandatory.This ZVEI informa a the lower explosion limit of 4% guide to the application of theDIN EN 62485-3 Safety requirements for secondary b

How do I identify a lead-acid battery charging station?

Signage should also indicate that the area is a designated lead-acid battery charging station. Signage – ensure PPE compliance, identify the eyewash station and fire extinguisher (required), and, of course, NO SMOKING signs in and around the area.

Can Apex Supply a lead-acid battery charging station?

Apex can meet all your needs when setting up a lead-acid battery charging station. We can supply chargers and safety products, design services, and training for your team. Apex is your material handling and warehouse supply source for the Chicagoland area. Contact your Apex rep today for prompt support.

What are lead acid batteries used for?

Batteries collected mainly include car batteries and other automotive application but also include lead acid batteries used for solar, UPS and other industrial applications. The popularity of this service and the BTS Containers is growing every year. Why Wood Pallets Shouldn’t Be Used For Transporting Lead Acid Batteries?

What is a flooded lead-acid battery?

Vented Lead-acid Batteries are commonly called “flooded” or “wet cell” batteries. These have thick lead-based plates that are flooded in an acid electrolyte. The electrolyte during charging emits hydrogen through the vents provided in the battery.

Guess what you want to know

-

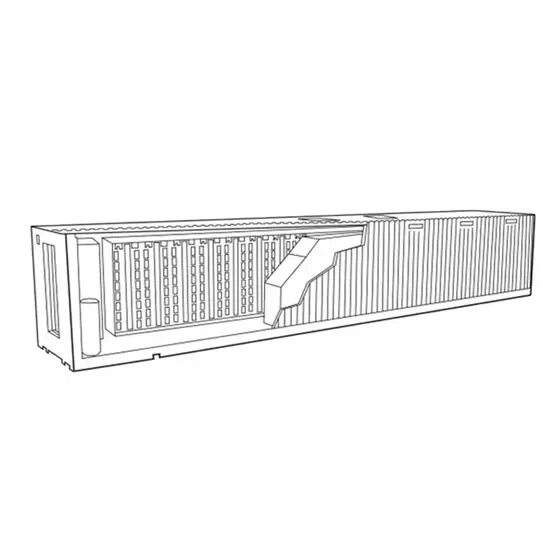

Lead-acid battery manufacturing ESS power base station container

Lead-acid battery manufacturing ESS power base station container

-

Base station lead-acid battery charging

Base station lead-acid battery charging

-

Somalia communication base station lead-acid battery cabinet in stock

Somalia communication base station lead-acid battery cabinet in stock

-

Malawi communication base station lead-acid battery equipment manufacturer

Malawi communication base station lead-acid battery equipment manufacturer

-

China-Europe communication base station lead-acid battery photovoltaic power generation external cooling

China-Europe communication base station lead-acid battery photovoltaic power generation external cooling

-

Battery component cost container base station

Battery component cost container base station

-

Base station lead-acid battery size specifications

Base station lead-acid battery size specifications

-

Tuvalu Communication Base Station Lead-Acid Battery 125kWh

Tuvalu Communication Base Station Lead-Acid Battery 125kWh

-

Indonesia communication base station lead-acid battery cooling chassis

Indonesia communication base station lead-acid battery cooling chassis

-

Communication base station lead-acid battery cooling chassis company

Communication base station lead-acid battery cooling chassis company

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.