Solar Manufacturing Cost Analysis | Solar Market Research & Analysis | NREL

NREL analyzes manufacturing costs associated with photovoltaic (PV) cell and module technologies and solar-coupled energy storage technologies.

Get a quote

What Are the 9 Operating Costs of a Solar Panel Manufacturing

Discover the 9 key ongoing expenses for running a solar panel manufacturing plant. Get actionable insights to control costs and boost efficiency.

Get a quote

Manufacturing and Competitiveness | Department of Energy

Read the Photovoltaic Supply Chain Strategy White Paper Research and development in solar manufacturing and competitiveness helps to build a strong clean energy manufacturing sector

Get a quote

Profitable Guide to Solar Panel Plant Setup Cost in

The solar energy industry in the world is growing as a result of the collective move towards renewable energy sources. One of the most potential

Get a quote

How Much Does It Cost to Start a Solar Panel

What are the typical costs to start a solar panel manufacturing plant? Starting a solar panel manufacturing plant can involve costs ranging from $500,000 to

Get a quote

What Are the 9 Startup Costs for a Solar Panel

Discover the 9 startup costs for a solar panel manufacturing plant. Learn about equipment, facilities, and operational expenses for success.

Get a quote

How Much Does It Cost to Start a Solar Panel Manufacturing Plant?

What are the typical costs to start a solar panel manufacturing plant? Starting a solar panel manufacturing plant can involve costs ranging from $500,000 to several million dollars,

Get a quote

Analogical environmental cost assessment of silicon flows used in solar

This study provides valuable insights into the environmental impacts of these two major solar panel manufacturing countries by examining the silicon life cycle, from production

Get a quote

How Much Does It Cost To Manufacture A Solar Panel?

For example, crystalline silicon solar panels typically cost between $0.50 and $1.00 per watt to manufacture. On the other hand, organic solar cells can cost between $2 and $4

Get a quote

Cost Breakdown of a Solar Panel: From Manufacturing to Market

This article delves into the comprehensive cost breakdown of solar panels, exploring the various facets of manufacturing costs, marketing and distribution expenses,

Get a quote

How much does it cost to manufacture a solar panel? Complete Cost

This comprehensive guide examines the intricate cost structure of solar panel manufacturing, from raw materials to finished products, while addressing the environmental

Get a quote

How much does it cost to manufacture a solar panel? Complete

This comprehensive guide examines the intricate cost structure of solar panel manufacturing, from raw materials to finished products, while addressing the environmental

Get a quote

Solar Manufacturing Cost Analysis | Solar Market

NREL analyzes manufacturing costs associated with photovoltaic (PV) cell and module technologies and solar-coupled energy storage

Get a quote

The True Cost of Solar: An In-Depth Analysis

Discover the true cost of solar energy cost analysis, hardware, and non-hardware costs. Learn about saving money and energy with solar today!

Get a quote

How Much Does it Cost to Make a Solar Panel

Uncover the details on ''how much does it cost to make a solar panel'' in our comprehensive guide. Learn all about solar panel production costs.

Get a quote

The 9 largest solar panel manufacturers in the world

Solar power is currently the world''s third largest renewable electricity technology after hydropower and wind (International Energy

Get a quote

Design and Cost Analysis of 100 MW Perovskite Solar

Moreover, the production of silicon used in most solar panels is energy-intensive and worsens the energy payback time (EPBT, eq S3) of both

Get a quote

The Hidden Environmental Costs of Solar Panel

Examining the environmental impact of manufacturing solar panels is crucial for a sustainable future. While solar energy offers a clean alternative

Get a quote

India Solar Panel Manufacturing Report | Market

Explore India solar panel manufacturing landscape through detailed market analysis, production statistics, and industry insights. Comprehensive data on

Get a quote

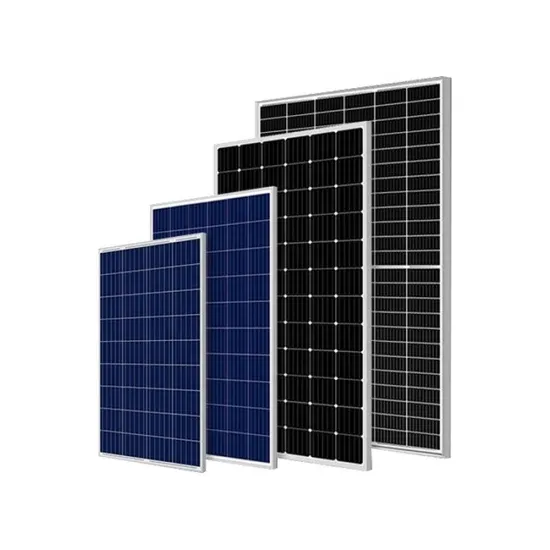

Solar Panel Manufacturing Cost: A Complete Factory Breakdown

Starting a solar panel factory? Get a detailed cost breakdown for machinery, buildings, and working capital for 25 MW, 100 MW, and 800 MW production lines.

Get a quote

Cost

Cost- and Price Dynamics of Solar PV Modules Abstract: For several decades, the prices for solar photovoltaic (PV) modules have adhered closely to an 80% learning curve. Yet recent price

Get a quote

Diversifying Solar Supply Chains: Costs and the Case for

The price of solar energy has plummeted over the last decade in large part due to the drop in manufacturing costs of solar photovoltaic (PV) technologies. Since 2009, the costs

Get a quote

How much does a solar panel manufacturer cost? | NenPower

HOW DO SOLAR PANEL MANUFACTURING COSTS COMPARE TO OTHER ENERGY SOURCES? The manufacturing costs associated with solar panels have seen a

Get a quote

Solar PV Module Manufacturing Cost Analysis | Case Study

We have developed a detailed financial model for the plant''s setup and operations. The proposed facility is designed with an annual production capacity of 1,000 MW (1 GW) of solar PV module.

Get a quote

Solar Photovoltaic Manufacturing Basics

Solar manufacturing encompasses the production of products and materials across the solar value chain. While some concentrating solar-thermal

Get a quote

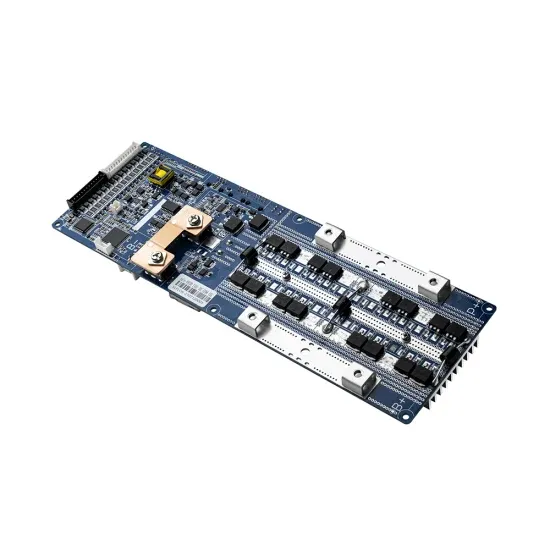

MANUFACTURING OF SOLAR PANELS: FROM CELL TO

Here we have emphasized on complete panel manufacturing process viz. Manufacturing of PV Cell, different types of PV Cell, Solar Panels, Testing of Solar Panels, Packaging & Quality

Get a quote

6 FAQs about [Cost of manufacturing solar photovoltaic panels]

What are solar panel manufacturing costs?

These costs encompass everything from equipment and labor to raw materials and operational expenses. In short, starting a solar panel manufacturing plant involves a complex web of financial considerations that must be navigated to ensure success. Overview of solar panel manufacturing costs. Breakdown of capital expenses.

How much do solar panels cost?

High-tech production lines backed by automation and AI can require upwards of $2 million to $5 million, depending on the plant’s scale. This cost falls under the overall solar panel manufacturing costs that also include equipment depreciation in solar plants. The solar panel production cost also hinges on the price of raw materials.

How much money do you need to produce solar panels?

To ensure you have enough stock to avoid stopping production due to a lack of materials, you should estimate approximately €6.5 million for working capital, including materials in stock. The cost of materials for solar panels constitutes over 95% of the total production costs, making it the dominant factor in solar module production.

Should you invest in solar panel manufacturing?

Investing in solar manufacturing is investing in a sustainable future. Once your solar panel manufacturing plant is up and running, it’s essential to keep a close eye on operating costs. These costs can significantly affect your profit margins. Key expenses include labor, utilities, maintenance, and raw materials.

How did our solar PV module manufacturing plant's financial model work?

Our solar PV module manufacturing plant's financial model was meticulously modelled to satisfy the client's requirements. It provided a thorough analysis of production costs including capital expenditures, manufacturing processes, raw materials, and operating costs.

What makes a solar panel factory a good investment?

The backbone of any solar panel factory operating costs starts with the procurement of high-quality raw materials. In a facility like SolarTech Innovations, securing premium silicon, glass, and other components is essential as these materials can represent up to 40% of the total solar panel manufacturing costs.

Guess what you want to know

-

How much does solar photovoltaic panels cost in South Africa

How much does solar photovoltaic panels cost in South Africa

-

Does installing solar photovoltaic panels cost money

Does installing solar photovoltaic panels cost money

-

Manufacturing solar photovoltaic panels

Manufacturing solar photovoltaic panels

-

Photovoltaic solar panels produced in Indonesia

Photovoltaic solar panels produced in Indonesia

-

Huijue New Energy Photovoltaic Solar Panels

Huijue New Energy Photovoltaic Solar Panels

-

Main structure of solar photovoltaic panels

Main structure of solar photovoltaic panels

-

Purchase 36V solar photovoltaic panels

Purchase 36V solar photovoltaic panels

-

Advantages and disadvantages of solar photovoltaic panels for power generation

Advantages and disadvantages of solar photovoltaic panels for power generation

-

Pakistan rooftop photovoltaic solar panels

Pakistan rooftop photovoltaic solar panels

-

Angola New Energy Photovoltaic Solar Panels

Angola New Energy Photovoltaic Solar Panels

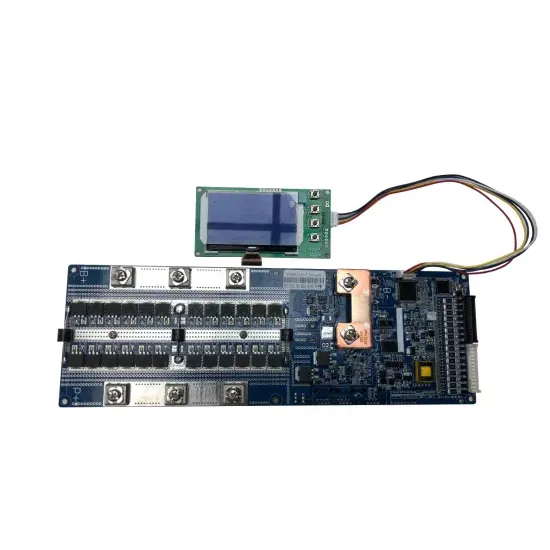

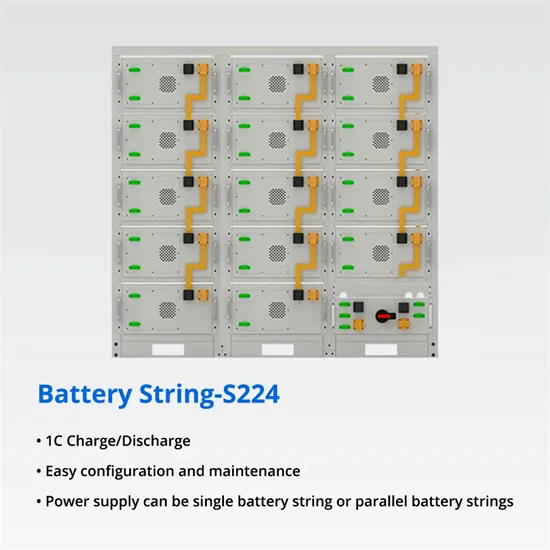

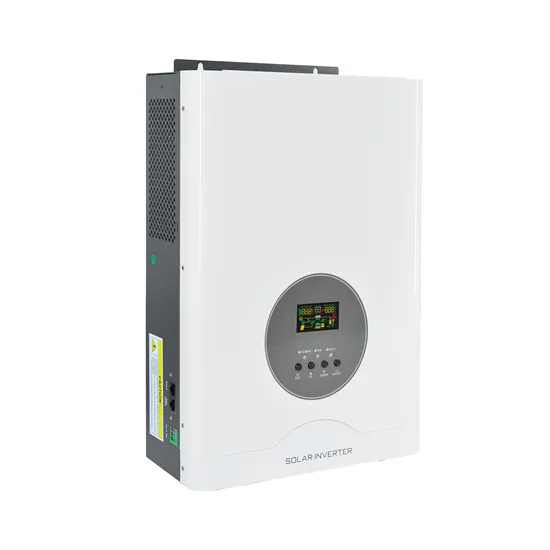

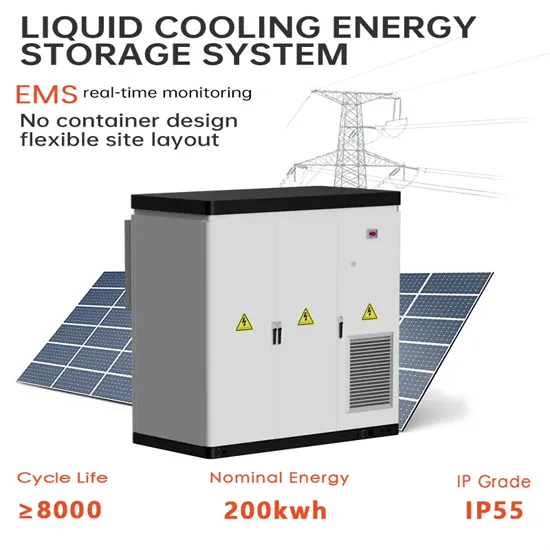

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.