Zinc-Bromine (ZNBR) Flow Batteries

In each cell of a zinc-bromine battery, two different electrolytes flow past carbon-plastic composite electrodes in two compartments, separated by a micro-porous polyolefin membrane.

Get a quote

Zinc–Bromine Rechargeable Batteries: From Device

The results of this study can contribute to the design of Zn-based composite anode materials for zinc–bromine flow batteries to achieve long-term operation with high performance.

Get a quote

Zinc–Bromine Rechargeable Batteries: From Device

The results of this study can contribute to the design of Zn-based composite anode materials for zinc–bromine flow batteries to achieve long-term operation

Get a quote

Research Progress of Zinc Bromine Flow Battery

Keywords: Zinc bromine redox flow battery; electrolyte; membrane; electrode In today''s society, the industry is highly developed, but it has caused a series of negative impacts, resulting in the

Get a quote

Bi-layer graphite felt as the positive electrode for zinc-bromine flow

Zinc-bromine flow battery (ZBFB) is one of the most promising energy storage technologies due to their high energy density and low cost. However, their efficiency and

Get a quote

Scientific issues of zinc‐bromine flow batteries and

In this review, the focus is on the scientific understanding of the fundamental electrochemistry and functional components of ZBFBs, with an

Get a quote

Aqueous Zinc‐Bromine Battery with Highly Reversible

In this study, we initially screen various aqueous electrolytes for KBr cathode and determine that ZnSO 4 is an optimal choice due to its

Get a quote

Zinc–Bromine Batteries: Challenges, Prospective Solutions, and

Zinc-bromine batteries (ZBBs) offer high energy density, low-cost, and improved safety. They can be configured in flow and flowless setups. However, their performance and

Get a quote

State-of-art of Flow Batteries: A Brief Overview

Zinc Bromine Flow Battery (ZBFB) In this flow battery system 1-1.7 M Zinc Bromide aqueous solutions are used as both catholyte and anolyte. Bromine

Get a quote

Zinc-Bromine Flow Battery

A zinc-bromine flow battery is defined as a type of flow battery that features a high energy density and can charge and discharge with a large capacity and a long life, utilizing an aqueous

Get a quote

Aqueous Zinc‐Bromine Battery with Highly Reversible Bromine

In this study, we initially screen various aqueous electrolytes for KBr cathode and determine that ZnSO 4 is an optimal choice due to its stronger repulsion with polybromides

Get a quote

The Zinc/Bromine Flow Battery: Materials Challenges

This book presents a detailed technical overview of short- and long-term materials and design challenges to zinc/bromine flow battery advancement, the need for

Get a quote

Zinc-Bromine (ZNBR) Flow Batteries

In each cell of a zinc-bromine battery, two different electrolytes flow past carbon-plastic composite electrodes in two compartments, separated by a micro

Get a quote

Predeposited lead nucleation sites enable a highly

Aqueous zinc-bromine flow batteries show promise for grid storage but suffer from zinc dendrite growth and hydrogen evolution reaction. Here,

Get a quote

Zinc-bromine flow battery systems

The zinc plating mechanism is central to the battery''s operation. During charging, Zn2+ ions in the aqueous electrolyte receive electrons and deposit as solid zinc on the electrode surface. This

Get a quote

DAT ZBM3 flow battery

About Redflow Redflow Limited, a publicly listed Australian company (ASX: RFX), produces zinc-bromine flow batteries for stationary energy storage applications. Redflow batteries are

Get a quote

Zinc Bromine Flow Batteries: Everything You Need To Know

Zinc bromine flow batteries are a promising energy storage technology with a number of advantages over other types of batteries. This article provides a comprehensive

Get a quote

A high-performance COF-based aqueous zinc-bromine battery

Nevertheless, the uncontrollable zinc dendrite growth and spontaneous shuttle effect of bromine species have prohibited their practical implementation. Herein, we develop

Get a quote

Zinc Bromine Flow Batteries: Everything You Need To

Zinc bromine flow batteries are a promising energy storage technology with a number of advantages over other types of batteries. This

Get a quote

A high-rate and long-life zinc-bromine flow battery

In this work, the effects of key design and operating parameters on the performance of ZBFBs are systematically analyzed and judiciously tailored to simultaneously minimize

Get a quote

ZINC/BROMINE

During charge, zinc is deposited at the negative electrode, and bromine is produced at the positive electrode. During discharge, zinc and bromide ions are formed at the respective

Get a quote

Zinc-Bromine Flow Battery

The technology behind zinc-bromine flow batteries involves a dual electrolyte system where zinc and bromine serve as the primary reactants, separated by a membrane

Get a quote

An Operating Control Strategy of Zinc Bromine Flow Battery

Firstly, the equivalent mathematical model based on the working principle of the zinc bromine flow battery is established; Secondly, a dual closed-loop strategy for the DC/DC converter is

Get a quote

Carbon Materials as Positive Electrodes in

Carbon materials demonstrate suitable physical and chemical properties for applications in bromine based redox flow batteries (RFBs). This

Get a quote

Scientific issues of zinc‐bromine flow batteries and mitigation

In this review, the focus is on the scientific understanding of the fundamental electrochemistry and functional components of ZBFBs, with an emphasis on the technical

Get a quote

Scientific issues of zinc‐bromine flow batteries and mitigation

Keywords: energy storage, flow battery, functional materials Zinc‐bromine flow batteries are a type of rechargeable battery that uses zinc and bromine in the electrolytes to

Get a quote

Guess what you want to know

-

Suriname zinc-bromine flow battery 75kwh

Suriname zinc-bromine flow battery 75kwh

-

Guinea-Bissau communication base station flow battery operation

Guinea-Bissau communication base station flow battery operation

-

Zinc-bromine flow battery in the Democratic Republic of the Congo

Zinc-bromine flow battery in the Democratic Republic of the Congo

-

Zinc-bromine non-fading liquid flow energy storage battery

Zinc-bromine non-fading liquid flow energy storage battery

-

Niue zinc-bromine flow energy storage battery

Niue zinc-bromine flow energy storage battery

-

Estonian flow battery prices

Estonian flow battery prices

-

Zinc flow battery

Zinc flow battery

-

Albania Vanadium Flow Battery Energy Storage Station

Albania Vanadium Flow Battery Energy Storage Station

-

Semi-solid lithium flow battery

Semi-solid lithium flow battery

-

Size effect realizes flow battery

Size effect realizes flow battery

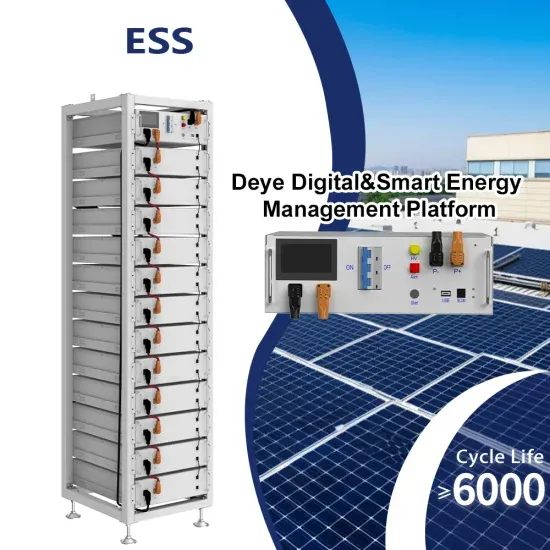

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.