Global PVB Double Glass Photovoltaic Module Market Growth

According to our (LP Information) latest study, the global PVB Double Glass Photovoltaic Module market size was valued at US$ million in 2022. With growing demand in downstream market

Get a quote

PVB Double Glass Photovoltaic Module Market Size, Potential,

The PVB Double Glass Photovoltaic Module Market refers to a specific segment of the solar energy industry that utilizes polyvinyl butyral (PVB) as a key component in the construction of

Get a quote

Properties and degradation behaviour of polyolefin

Polyvinyl butyral (PVB) encapsulants have found a niche market for double-glass modules. The material is characterized by a stronger

Get a quote

CN114361279B

The invention discloses a PVB double-glass photovoltaic module structure and a press mounting process, which belong to the technical field of double-glass photovoltaic module...

Get a quote

PVB Double Glass Photovoltaic Module Insightful Market

PVB double-glass photovoltaic modules represent a significant advancement in solar technology, offering superior durability, efficiency, and longevity compared to traditional modules.

Get a quote

si-esf-m-bipv-ct-catalog-en

The BIPV glass/glass PV modules are made of two sheets of tempered glass at its peak including photovoltaic solar cells allowing access of light depends on the distance between each of the

Get a quote

Jiaxing Fuying Composite Materials Co., Ltd.

The company is committed to building a composite functional film, PVB double glass photovoltaic module application demonstration and promotion base, and a PVB research institute, forming

Get a quote

Global PVB Double Glass Photovoltaic Module Market Research

The report will help the PVB Double Glass Photovoltaic Module companies, new entrants, and industry chain related companies in this market with information on the revenues for the

Get a quote

Why PVB Double Glass Photovoltaic Modules Are

If you''re exploring PVB double glass photovoltaic module company options, you''re already ahead in the renewable energy game. These advanced solar panels combine two layers of tempered

Get a quote

Global PVB Double Glass Photovoltaic Module Supply, Demand

The global PVB Double Glass Photovoltaic Module market size is expected to reach $ million by 2029, rising at a market growth of % CAGR during the forecast period (2023-2029).

Get a quote

Global PVB Double Glass Photovoltaic Module Market Growth

According to our LPI (LP Information) latest study, the global PVB Double Glass Photovoltaic Module market size was valued at US$ million in 2023. With growing demand in downstream

Get a quote

Double the strengths, double the benefits

In the ever-evolving world of photovoltaic technology, double glass solar modules are emerging as a game-changer. By encapsulating solar cells between two layers of glass,

Get a quote

Global PVB Double Glass Photovoltaic Module Market 2024 by

Regionally, the report analyzes the PVB Double Glass Photovoltaic Module markets in key regions. North America and Europe are experiencing steady growth, driven by government

Get a quote

PVB Double Glass Photovoltaic Module Market, Report Size, Worth,

PVB Double Glass Photovoltaic Module Market global PVB Double Glass Photovoltaic Module market is projected to reach US$ million in 2029, increasing from US$ million in 2022, with the

Get a quote

PVB Double Glass Photovoltaic Module Analysis 2025-2033:

Regional analysis reveals that Asia Pacific holds the dominant share in the PVB double glass photovoltaic module market, with China being the major contributor.

Get a quote

Global PVB Double Glass Photovoltaic Module Market 2024 by

Chapter 2, to profile the top manufacturers of PVB Double Glass Photovoltaic Module, with price, sales, revenue and global market share of PVB Double Glass Photovoltaic Module from 2019

Get a quote

PV Solar Panels Module Blue Color Custom

PV Solar Panels Module Blue Color Custom PVB Double Glass PV Module, Select Fuying New Materkals! PV Solar Panels Module Blue Color Half-cell

Get a quote

Global PVB Double Glass Photovoltaic Module Market 2023 by

PVB double glass photovoltaic modules use self-produced photovoltaic-grade PVB materials with high adhesive strength, high water resistance, high volume resistivity, and high light

Get a quote

What is the Double Glass (Dual Glass) Photovoltaic Solar Panel?

What is the Double Glass Photovoltaic Solar Panel? Glass-glass module structures (Dual Glass or Double Glass) is a technology that uses a glass layer on the back of the modules instead of

Get a quote

Custom PVB double glass module Suppliers, ODM Company

PVB Double Glass PV Module, Select Fuying New Materkals! PVB double glass module Half-cell battery technology, brand new circuit design. Super frame, can bear 5400Pa mechanical load

Get a quote

Why PVB Double Glass Photovoltaic Modules Are

These advanced solar panels combine two layers of tempered glass with polyvinyl butyral (PVB) interlayers - think of it like a high-tech solar sandwich that outperforms traditional modules.

Get a quote

BIPV Solar panel auto production line

– High-precision solar module production lines, suitable for both standard and advanced solar panel configurations. – Automated assembly lines that

Get a quote

Double the strengths, double the benefits

In the ever-evolving world of photovoltaic technology, double glass solar modules are emerging as a game-changer. By encapsulating solar cells

Get a quote

Global PVB Double Glass Photovoltaic Module Market Research

PVB double glass photovoltaic modules use self-produced photovoltaic-grade PVB materials with high adhesive strength, high water resistance, high volume resistivity, and high light

Get a quote

6 FAQs about [Pvb double-glass photovoltaic module project]

Are double-glass PV modules durable?

Double-glass PV modules are emerging as a technology which can deliver excellent performance and excellent durability at a competitive cost. In this paper a glass–glass module technology that uses liquid silicone encapsulation is described. The combination of the glass–glass structure and silicone is shown to lead to exceptional durability.

What is a double glass c-Si PV module?

Recently several double-glass (also called glass–glass or dual-glass modules) c-Si PV modules have been launched on the market, many of them by major PV manufacturers. These modules use a sheet of tempered glass at the rear of the module instead of the conventional polymer-based backsheet. There are several reasons why this structure is appealing.

What is polyvinyl butyral (PVB)?

Polyvinyl butyral (PVB) has been used for a long time for glass–glass PV modules, particularly for thin-film modules. For various reasons (it entails a longer, more complicated process, and comparatively high water uptake), this is not the preferred material for modern crystalline Si double-glass modules.

What encapsulant materials can be used for PV modules?

Various encapsulant materials can be considered. Polyvinyl butyral (PVB) has been used for a long time for glass–glass PV modules, particularly for thin-film modules.

Are early PV modules encapsulated with silicone?

Photovoltaics International Early PV modules were often encapsulated with silicone, and have demonstrated outstanding stability in the field, with degradation rates over 20 to 30 years that are much lower than the typical degradation rates for EVA-encapsulated modules [3–5].

How do PV installation blocks work?

The installation blocks are designed and placed on the laminate in such a way that they can be bolted onto two brackets with a U-shaped cross section. Each pair of brackets will typically carry several modules, the number of which depends on the PV system design (Fig. 3).

Guess what you want to know

-

Photovoltaic module automation project

Photovoltaic module automation project

-

Huawei Niger photovoltaic module project

Huawei Niger photovoltaic module project

-

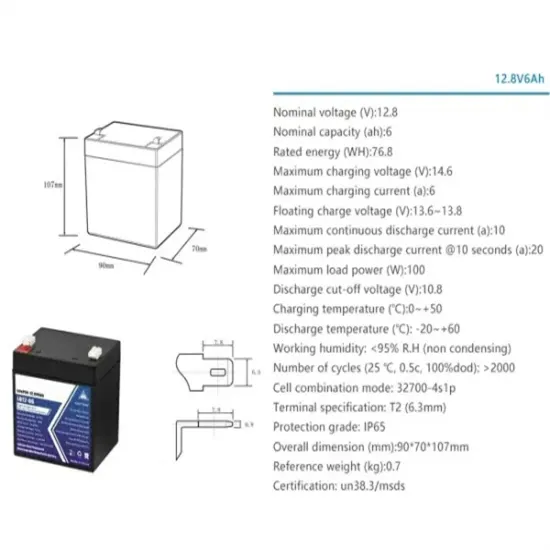

Double-glass photovoltaic module performance parameters

Double-glass photovoltaic module performance parameters

-

Danish photovoltaic module project

Danish photovoltaic module project

-

Photovoltaic double-glass module back connector

Photovoltaic double-glass module back connector

-

Sao Tome and Principe Huijue Photovoltaic Module Project

Sao Tome and Principe Huijue Photovoltaic Module Project

-

Guatemala Photovoltaic Cell Module Project

Guatemala Photovoltaic Cell Module Project

-

Huawei photovoltaic module engineering project

Huawei photovoltaic module engineering project

-

Photovoltaic double-glass module installation

Photovoltaic double-glass module installation

-

Photovoltaic Module Project Plan

Photovoltaic Module Project Plan

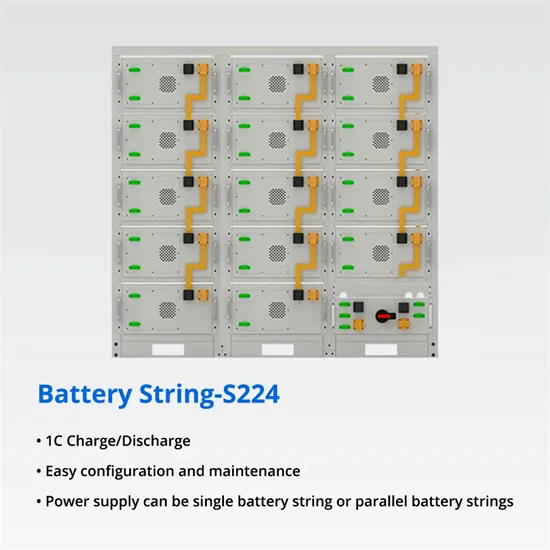

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.