Solar PV Module Manufacturing Cost Analysis | Case

Looking ahead, the market is expected to grow at a CAGR of approximately 14.36% from 2025 to 2033, reaching a projected capacity of 4,919.2 TWh by

Get a quote

Cost Breakdown of a Solar Panel: From Manufacturing to Market

This article delves into the comprehensive cost breakdown of solar panels, exploring the various facets of manufacturing costs, marketing and distribution expenses,

Get a quote

Solar Panel Manufacturing Cost: A Complete Factory Breakdown

Starting a solar panel factory? Get a detailed cost breakdown for machinery, buildings, and working capital for 25 MW, 100 MW, and 800 MW production lines.

Get a quote

Solar Panel Manufacturing Costs: Budget Planning

Empower your solar business model with an understanding of the key cost drivers behind your solar panel production plant startup costs.

Get a quote

Solar PV Module Manufacturing Cost Analysis | Case Study

Looking ahead, the market is expected to grow at a CAGR of approximately 14.36% from 2025 to 2033, reaching a projected capacity of 4,919.2 TWh by 2033. A number of important factors

Get a quote

Solar Panel Manufacturing Costs

When considering the key cost factors in solar panel manufacturing, you''ll want to focus on material costs, labour expenses, and energy usage. These factors play a significant

Get a quote

How Much Does It Cost to Start a Solar Panel Manufacturing Plant?

Building a manufacturing facility could range from $500,000 to several million dollars, depending on size and technology. Equipment such as solar cell production lines, laminators, and testing

Get a quote

Solar Manufacturing Cost Analysis | Solar Market

The costs of materials, equipment, facilities, energy, and labor associated with each step in the production process are individually modeled.

Get a quote

The economics of concentrating solar power (CSP): Assessing cost

Compared to solar PV and onshore wind alternatives, CSP cannot currently compete on the levelized cost of electricity (LCoE). This review provides a comprehensive

Get a quote

Solar Manufacturing Cost Analysis | Solar Market Research & Analysis | NREL

The costs of materials, equipment, facilities, energy, and labor associated with each step in the production process are individually modeled. Input data for this analysis method are

Get a quote

Drivers of cost reduction in solar photovoltaics

1. Introduction The solar photovoltaic industry has expanded rapidly in the last few years. Annual production of solar panels has increased by a factor of six-teen during the period 2005 –2012,

Get a quote

Cost Breakdown of a Solar Panel: From

This article delves into the comprehensive cost breakdown of solar panels, exploring the various facets of manufacturing costs, marketing and

Get a quote

U.S. Solar Manufacturing Capacity: Q2 2024 Analysis

U.S. solar module manufacturing capacity reaches over 31 GW in Q2 2024 under new federal incentives but continues to face resistance. This

Get a quote

Solar Photovoltaics Supply Chain Review Report

The Solar Photovoltaics Supply Chain Review, produced by the DOE Solar Energy Technologies Office with support from the National Renewable Energy Laboratory, will help

Get a quote

How much does a solar panel manufacturer cost? | NenPower

In examining the realm of solar panel manufacturing, it''s essential to consider the numerous factors that directly influence costs. A holistic perspective reveals economies of

Get a quote

What Are the 9 Operating Costs of a Solar Panel Manufacturing

Discover the 9 key ongoing expenses for running a solar panel manufacturing plant. Get actionable insights to control costs and boost efficiency.

Get a quote

How China Came to Dominate the World in Solar Energy

Beijing is set to further increase its manufacturing and installation of solar panels as it seeks to master global markets and wean itself from imports.

Get a quote

Solar Energy Trends 2025 | Future Solar Power

Trend 1: Advancements in Solar Panel Technology The world of solar panel technology is evolving rapidly, with innovations designed to improve efficiency,

Get a quote

India''s solar module manufacturing capacity on track

Capacity As of March 31, India had 3GW of solar cell capacity, mostly used for the in-house production of modules, and 8GW of effective

Get a quote

SolGo Solar Panels SG-55W-SW-10YR | Fisheries Supply

Save More on Your SolGo Solar Panels #SG-55W-SW-10YR SOG SG-55W-SW-10YR FLEXIBLE SOLAR PANEL 55W MAXEON 10YR WAR at Fisheries Supply. Excellent Customer Service,

Get a quote

Start your Solar Energy Panel Manufacturing Journey:

Below is a table outlining the average startup costs for different aspects of a manufacturing business. Acquiring suitable land for the

Get a quote

Start your Solar Energy Panel Manufacturing Journey: Learn the Costs!

Below is a table outlining the average startup costs for different aspects of a manufacturing business. Acquiring suitable land for the establishment of a solar panel

Get a quote

How much does a solar panel manufacturer cost?

In examining the realm of solar panel manufacturing, it''s essential to consider the numerous factors that directly influence costs. A holistic

Get a quote

Solar Panel Manufacturing Costs: Budget Planning Made Easy

Empower your solar business model with an understanding of the key cost drivers behind your solar panel production plant startup costs. Location, facility size, manufacturing

Get a quote

What Are the 9 Startup Costs for a Solar Power

What are the 9 essential startup costs for a solar power company, and how can you strategically manage them to ensure success? From

Get a quote

Solar Market Insight Report – SEIA

4 days ago· learn more About the Report U.S. Solar Market Insight® is a quarterly publication of the Solar Energy Industries Association (SEIA)® and

Get a quote

6 FAQs about [Solar panel production expansion costs]

What are solar panel manufacturing costs?

These costs encompass everything from equipment and labor to raw materials and operational expenses. In short, starting a solar panel manufacturing plant involves a complex web of financial considerations that must be navigated to ensure success. Overview of solar panel manufacturing costs. Breakdown of capital expenses.

How to manage the running costs in a solar panel manufacturing plant?

In a solar panel manufacturing plant like SolarTech Innovations, managing the running costs is crucial for maintaining a competitive edge. One of the key categories is overseeing the expenses related to equipment maintenance and repair schedules.

How does energy consumption affect a solar panel manufacturing plant?

The energy consumption of a solar panel manufacturing plant is not just about powering machinery. It impacts the overall solar panel manufacturing costs significantly. For instance, energy expenses can account for up to 30% of total operational costs in similar facilities.

How to reduce solar panel manufacturing costs?

In a state-of-the-art facility like SolarTech Innovations, raw materials including high-purity silicon and specialty glass dominate the solar panel manufacturing costs. Bulk purchase agreements and strategic sourcing have proven to reduce these photovoltaic manufacturing expenses significantly.

How does market demand affect solar panel pricing?

Market demand analysis plays a crucial role in influencing solar panel pricing. Cost reduction strategies such as streamlining production processes and optimizing supply chain management can help lower manufacturing costs. Research and development investments can improve efficiency and reduce material wastage, leading to cost savings.

Why do solar panels cost so much?

The location of your solar panel manufacturing plant can greatly influence both initial and ongoing costs. Factors such as proximity to suppliers, labor availability, and transportation infrastructure all play a role in determining your overall expenses.

Guess what you want to know

-

Flexible solar panel production

Flexible solar panel production

-

Solar panel curtain wall production

Solar panel curtain wall production

-

Production of solar panel charging system

Production of solar panel charging system

-

Burkina Faso solar photovoltaic panel production equipment

Burkina Faso solar photovoltaic panel production equipment

-

Solar photovoltaic panel production in Mexico

Solar photovoltaic panel production in Mexico

-

Solar panel costs in photovoltaics

Solar panel costs in photovoltaics

-

Photovoltaic bifacial solar panel production

Photovoltaic bifacial solar panel production

-

Solar panel production cost reduction price

Solar panel production cost reduction price

-

Terrace solar panel production in South Africa

Terrace solar panel production in South Africa

-

Solar panel expansion project

Solar panel expansion project

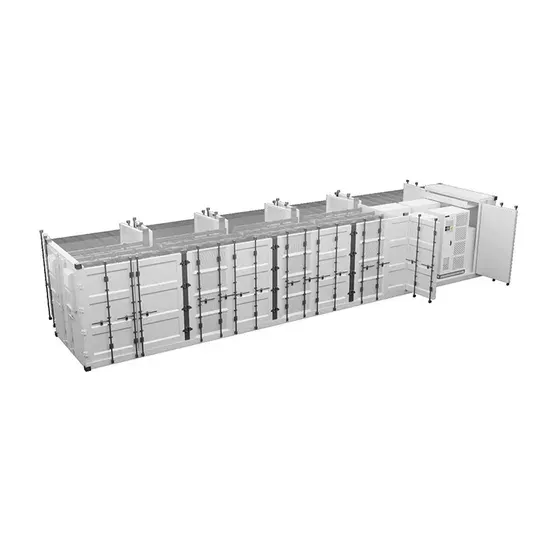

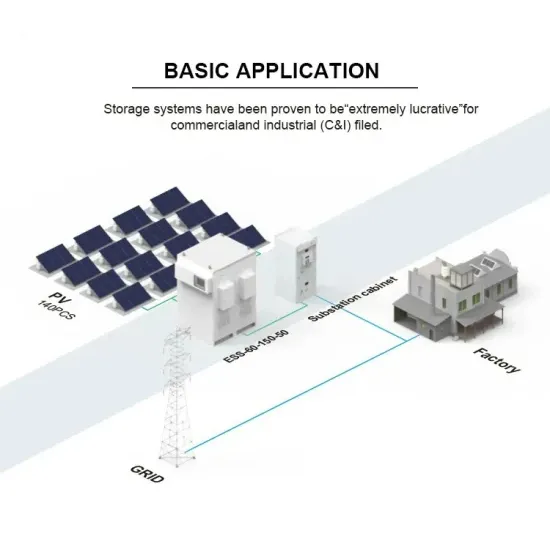

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

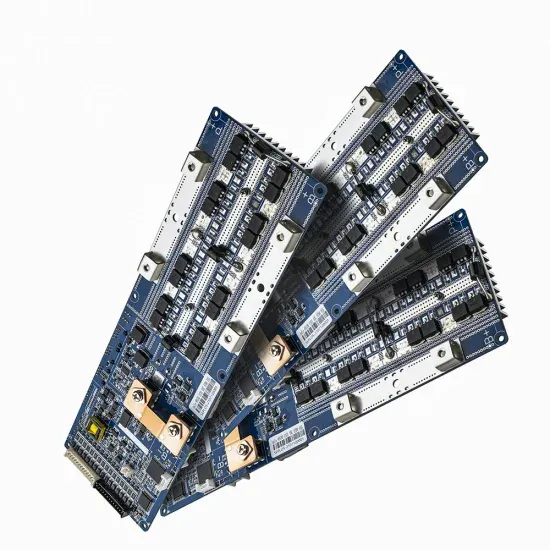

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.