Global Iron and Steel Tracker

Global Iron and Steel Tracker The Global Iron and Steel Tracker (GIST) provides information on global crude iron and steel production plants, and includes

Get a quote

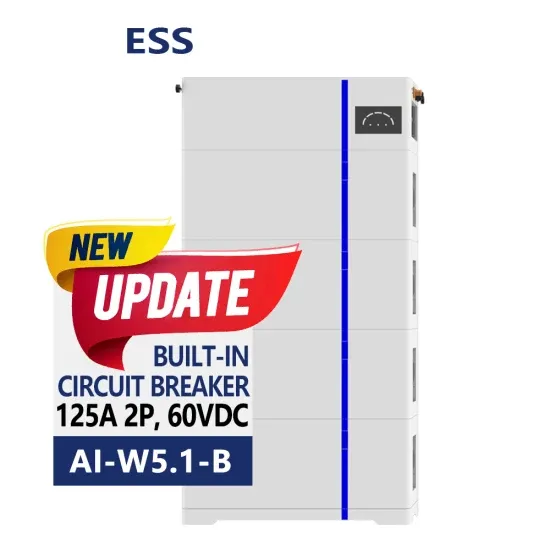

The benefits of installing energy storage in steel plants

By building energy storage systems in steel plants, companies can charge during off-peak hours and discharge during peak hours, effectively adjusting peak and valley power

Get a quote

Electric Energy Storage

Electric Energy Storage (EES) is defined as a technology that stores electrical energy for various applications, including enhancing renewable power generation, supporting grid stability, and

Get a quote

FACT SHEET Energy use in the steel industry

Energy use in the steel industry The steel industry actively manages the use of energy. Energy conservation in steelmaking is crucial to ensure the competitiveness of the industry and to

Get a quote

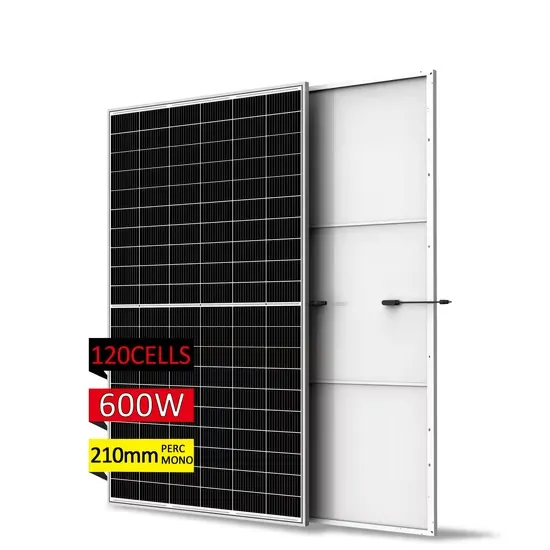

Renewable Energy Storage Systems

Efficient renewable energy storage systems enhance grid stability, store excess energy from solar and wind, and ensure a reliable, sustainable power supply.

Get a quote

Fluence | A Siemens and AES Company

Fluence offers energy storage products that are optimized for common customer applications but can be configured for specific use cases and requirements. All Fluence products can be

Get a quote

Optimizing Energy Use in Steel Plants with Smart Grid Technology

Smart grids also support energy storage solutions, allowing plants to store surplus power generated during low-demand periods or from renewables. This stored energy can then be

Get a quote

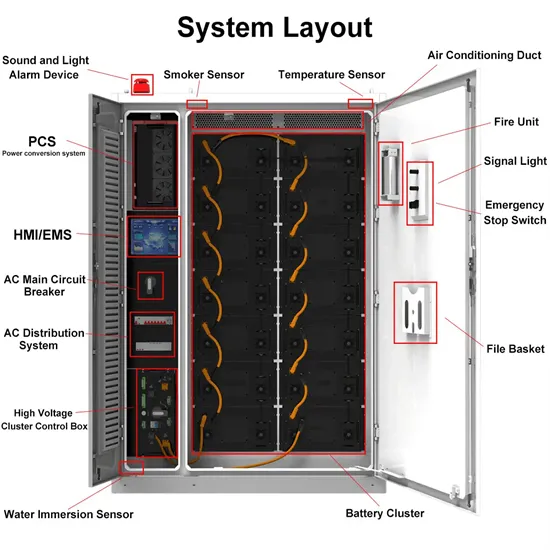

Layout 1

To incorporate battery storage into an industrial plant, Figure 2 shows a schematic of the energy power supplies and how a battery could be located in a system operating either an AC or DC

Get a quote

Structural Steel in Renewable Energy

Structural steel is the sustainable choice for renewable energy systems and facilities. It''s strong, durable, and cost-effective for solar and more.

Get a quote

1.Steam Thermal Power Plant and Coal Handling | PPTX | Power and Energy

This document provides information about the coal handling system used in steam thermal power plants. It discusses the various components of a coal handling system including coal delivery,

Get a quote

Material and energy flows of the iron and steel industry: Status

Integrated analysis and optimization of material and energy flows in the iron and steel industry have drawn considerable interest from steelmakers, energy engineers,

Get a quote

Electric Arc Furnace: The Future of Sustainable Steel

Electric Arc Furnace (EAF) steelmaking leads the shift to sustainable steel, using steel scrap and electricity to cut emissions and improve efficiency over BOF.

Get a quote

Management of Energy in a Steel Plant – IspatGuru

Electricity is usually purchased through the utilities companies at high voltage. Generated energies – Generated energies are those energies

Get a quote

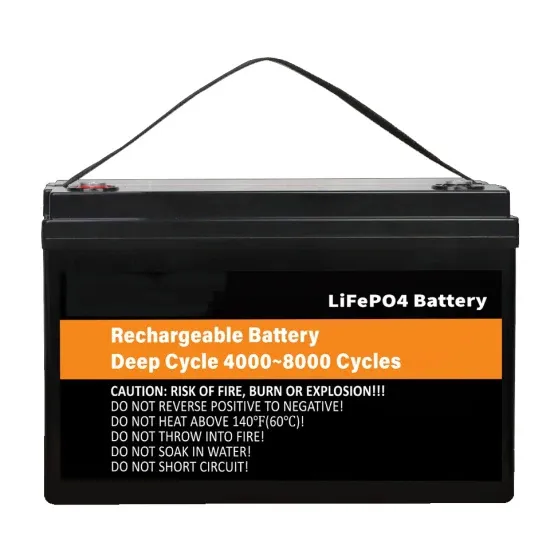

The search for long-duration energy storage

Over the past few years, lithium-ion batteries emerged as the default choice for storing renewable energy on the electrical grid. The batteries

Get a quote

The search for long-duration energy storage

The Long Duration Energy Storage Council, a group that advocates on behalf of companies developing these technologies, estimates that the amount of long

Get a quote

What are the energy storage power stations in steel plants?

Energy storage power stations in steel manufacturing facilities represent a vital evolution in enhancing operational efficiency and environmental sustainability.

Get a quote

STEEL PLANT ELECTRIFICATION

We are a trusted leader in all types of power conversion equipment, including high-power rectifiers, inverters, DC-DC converters, integrated battery energy storage systems, and

Get a quote

Steel Plant Energy Storage: Powering the Future of Sustainable

At the precipice of a steel revolution where energy storage applications aren''t just supporting production – they''re becoming profit centers. The next time you see a skyscraper,

Get a quote

ArcelorMittal to trial electric heating and thermal energy storage

ETS has developed the Joule Hive™ Thermal Battery (JHTB), a system made of electrically and thermally conductive firebricks contained within an insulated steel unit. It

Get a quote

Steel Mill Machinery: The Basic Equipment and Roles

Steel mill machinery is one of the most important equipment in steel production. These machines are used in many different stages of steel production, from

Get a quote

Types of Energy used in a Steel Plants and Energy Conservation

Fig 1 Types of fuel energies used in steel plant Other form of energy used in steel plants After fuel energy, electricity constitute the next highest consumption of energy in the

Get a quote

What does the steel plant energy storage system include?

Diverse energy storage technologies are integral to a steel plant''s energy storage system. The most commonly utilized solutions are batteries, pumped hydro storage, and

Get a quote

What does the steel plant energy storage system

Diverse energy storage technologies are integral to a steel plant''s energy storage system. The most commonly utilized solutions are batteries,

Get a quote

Steel Plant Energy Storage Power Stations: Solving Heavy

But here''s the kicker: about 35% of that energy gets wasted through inefficient load management and grid dependency. That''s where steel plant energy storage power stations come roaring in

Get a quote

Guess what you want to know

-

Solid Electric Energy Storage Equipment Project

Solid Electric Energy Storage Equipment Project

-

What are the equipment of electric energy storage vehicles

What are the equipment of electric energy storage vehicles

-

Electric energy storage equipment sales

Electric energy storage equipment sales

-

Heishan Electric Energy Storage Equipment Manufacturer

Heishan Electric Energy Storage Equipment Manufacturer

-

China-Europe Energy Storage Equipment Manufacturer

China-Europe Energy Storage Equipment Manufacturer

-

Mobile power generation and energy storage equipment

Mobile power generation and energy storage equipment

-

Japanese automated energy storage equipment manufacturer

Japanese automated energy storage equipment manufacturer

-

Democratic Congo energy storage equipment manufacturers direct sales

Democratic Congo energy storage equipment manufacturers direct sales

-

Lithuanian container energy storage equipment company

Lithuanian container energy storage equipment company

-

Netherlands Energy Storage Equipment Manufacturer

Netherlands Energy Storage Equipment Manufacturer

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.