Optimizing the power supply design for communication base stations

The design of the power supply system of the communication base station is critical to ensure the stable operation of the equipment.

Get a quote

Telecom Base Station Backup Power Solution: Design Guide for

Designing a 48V 100Ah LiFePO4 battery pack for telecom base stations requires careful consideration of electrical performance, thermal management, safety protections, and

Get a quote

Modeling and aggregated control of large-scale 5G base stations

The limited penetration capability of millimeter waves necessitates the deployment of significantly more 5G base stations (the next generation Node B, gNB) than their 4G

Get a quote

HUAWEI DBS3900 Dual-Mode Base Station Hardware

DBS3900 Dual-Mode Base Station is the fourth generation base station developed by Huawei. It features a multi-mode modular design and supports three working modes: GSM mode,

Get a quote

Power Supply Solutions for Wireless Base Stations Applications

Power supplies can be employed in each of the three systems that compose wireless base stations. These three systems are known as the environmental monitoring system, the data

Get a quote

Energy Management of Base Station in 5G and B5G: Revisited

Since mmWave base stations (gNodeB) are typically capable of radiating up to 200-400 meters in urban locality. Therefore, high density of these stations is required for actual 5G deployment,

Get a quote

Sentry 4G-900 Pico Base Station

Power Cord Protection The Sentry 4G-900 Pico Base Station should always be connected to the supplied data adapter for both power supply and data transfer purposes. Any other type of

Get a quote

Communication Base Station Energy Solutions

During the day, the solar system powers the base station while storing excess energy in the battery. At night, the energy storage system discharges to

Get a quote

Communication Base Station Energy Solutions

During the day, the solar system powers the base station while storing excess energy in the battery. At night, the energy storage system discharges to supply power to the base station,

Get a quote

Base Stations

Power Supply: The power source provides the electrical energy to base station elements. It often features auxiliary power supply mechanisms that guarantee operation in

Get a quote

(PDF) Dispatching strategy of base station backup power supply

However, a significant reduction of ca. 42.8% can be achieved by optimizing the power structure and base station layout strategy and reducing equipment power consumption.

Get a quote

Optimizing the power supply design for communication base stations

Comprehensively evaluate various factors and select the most suitable power system design scheme to ensure the stable and reliable operation of the base station.

Get a quote

Telecom Base Station Backup Power Solution: Design

Designing a 48V 100Ah LiFePO4 battery pack for telecom base stations requires careful consideration of electrical performance, thermal

Get a quote

Analysis of energy efficiency of small cell base station in 4G/5G

Base Stations (BSs) sleeping strategy is an efficient way to obtain the energy efficiency of cellular networks. To meet the increasing demand of high-data-rate for wireless

Get a quote

Adaptive power supply unit: A solution for efficient 4G macro-cell

As global consumption of mobile network is increasing, 4G base station must be designed in a context of improvement in power efficiency. This article presents a

Get a quote

Adaptive power supply unit: A solution for efficient 4G macro-cell base

As global consumption of mobile network is increasing, 4G base station must be designed in a context of improvement in power efficiency. This article presents a

Get a quote

Details of the power consumption for an LTE-macro

In terms of energy-saving effect, calculating using the power parameters of a typical 4G (LTE 2T2R) base station 30 Besides, an examination of the results

Get a quote

Telecommunication base station system working principle and

After the oil engine is working normally, it can provide AC input power to the rectifier module, which will re supply power to the communication equipment and charge the

Get a quote

Optimal configuration of 5G base station energy storage

Abstract: The high-energy consumption and high construction density of 5G base stations have greatly increased the demand for backup energy storage batteries. To maximize overall

Get a quote

Application of AI technology 5G base station

Introduction of energy saving of 5g There are mainly two method of base station energy saving, which are hardware power saving and software energy saving.

Get a quote

huawei base station

Power Supply Unit (PSU): This provides the necessary electrical power to operate the base station components. It ensures that all parts of the base station have a consistent

Get a quote

Introduction of base station and Remote Radio Unit

Base Station, generally refers to the public mobile communication base station, the base station is used to provide signals to mobile phones. It

Get a quote

5G network deployment and the associated energy

However, the total power consumption of a single 5G base station is about four times that of a single 4G base station and considering the high density the overall power

Get a quote

6 FAQs about [4G base station power supply equipment operation]

What are the components of a base station?

Power Supply: The power source provides the electrical energy to base station elements. It often features auxiliary power supply mechanisms that guarantee operation in case of lost or interrupted electricity, during blackouts. Baseband Processor: The baseband processor is responsible for the processing of the digital signals.

How much power does a cellular base station use?

This problem exists particularly among the mobile telephony towers in rural areas, that lack quality grid power supply. A cellular base station can use anywhere from 1 to 5 kW power per hour depending upon the number of transceivers attached to the base station, the age of cell towers, and energy needed for air conditioning.

What type of generator does a base station use?

The air conditioning of the base station runs at 220 VAC. These base stations can be powered by two types of diesel generators. The first is the conventional type where 220 VAC is converted to 48 VDC to charge the batteries and power the communication equipment.

Why do cellular base stations need maintenance?

Cellular base stations use power without any interruption and also needs maintenance. The increase in demand of power base stations from Indian telecommunication industry is a big challenge, especially in rural India.

How do you protect a telecom base station?

Backup power systems in telecom base stations often operate for extended periods, making thermal management critical. Key suggestions include: Cooling System: Install fans or heat sinks inside the battery pack to ensure efficient heat dissipation.

Which battery is best for telecom base station backup power?

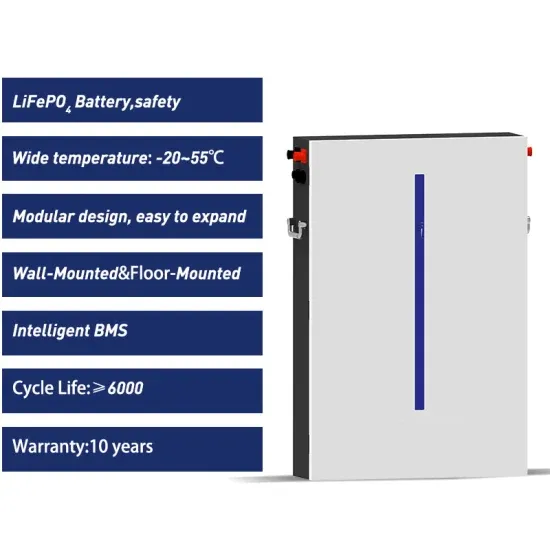

Among various battery technologies, Lithium Iron Phosphate (LiFePO4) batteries stand out as the ideal choice for telecom base station backup power due to their high safety, long lifespan, and excellent thermal stability.

Guess what you want to know

-

Vatican Base Station Power Cabinet Power Supply Equipment

Vatican Base Station Power Cabinet Power Supply Equipment

-

What is the power supply type of 5G base station equipment

What is the power supply type of 5G base station equipment

-

Base station wind power supply equipment model

Base station wind power supply equipment model

-

Increase the power supply of mobile base station equipment

Increase the power supply of mobile base station equipment

-

5G base station power supply equipment

5G base station power supply equipment

-

Communication base station power supply equipment system

Communication base station power supply equipment system

-

Power communication base station inverter grid-connected 4G to 3G

Power communication base station inverter grid-connected 4G to 3G

-

5g small base station power supply supporting company

5g small base station power supply supporting company

-

Base station replaces wind power supply and wind power generation screen

Base station replaces wind power supply and wind power generation screen

-

Base station power supply load current

Base station power supply load current

Industrial & Commercial Energy Storage Market Growth

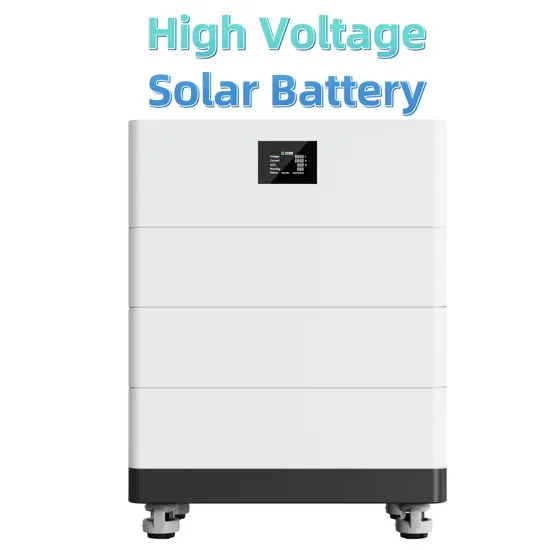

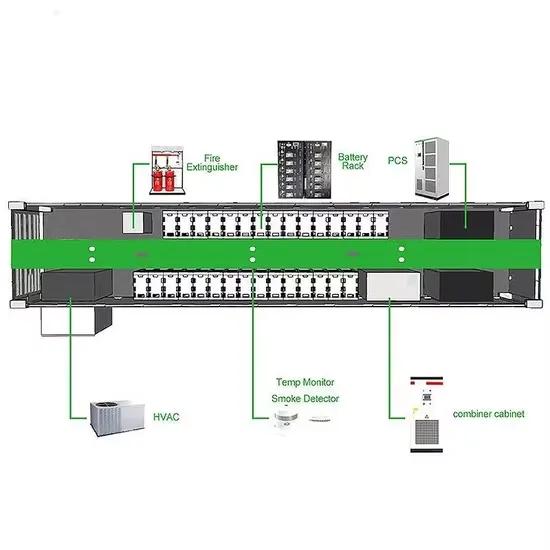

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

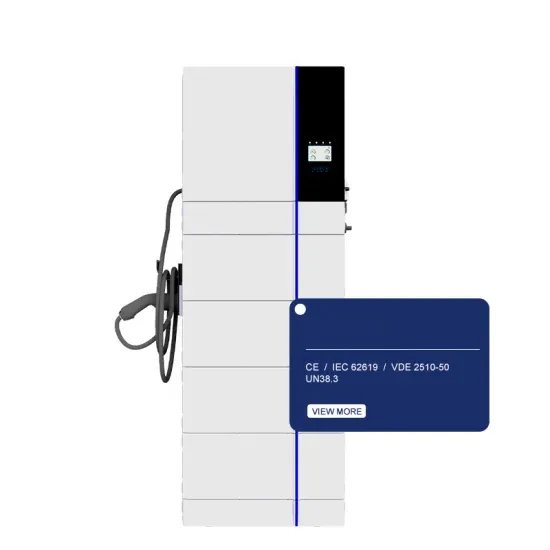

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.