Telecommunication base station system working principle and

The system output load and battery charging current are provided by the solar module. If the output power of the solar module is not enough to provide all loads, it is

Get a quote

The Ultimate Guide to 18650 Battery Packs: Design,

This comprehensive guide explores the 18650 battery pack''s structure, applications, design principles, and charging protocols—optimized for SEO to

Get a quote

How about base station energy storage batteries | NenPower

One significant aspect of these batteries is their ability to improve grid resilience, which is crucial in areas prone to power interruptions. This detailed analysis provides an

Get a quote

Long-Lasting 48V 100Ah LiFePO4 Battery Pack for Telecom,

Telecom Base Stations: Ensure uninterrupted operation of your 5G base station with this long-lasting and dependable LiFePO4 battery pack. Uninterruptible Power Supply (UPS): Provide

Get a quote

Fundamentals of battery charging: Part 1

While the battery pack in use determines the theoretical charge current required for the battery during the different charging phases, system

Get a quote

Telecom Base Station Backup Power Solution: Design

This guide outlines the design considerations for a 48V 100Ah LiFePO4 battery pack, highlighting its technical advantages, key design

Get a quote

Understanding Backup Battery Requirements for

Telecom base stations require reliable backup power to ensure uninterrupted communication services. Selecting the right backup battery is

Get a quote

Base station battery pack voltage collection

What are the operating conditions of a battery pack? The operating conditions of battery pack are different from those of single cell,with the former typically utilizing a multi-stage constant

Get a quote

What Are the Critical Aspects of Telecom Base Station Backup

Critical aspects include battery chemistry, capacity, cycle life, safety features, thermal management, and intelligent battery management systems. These factors collectively

Get a quote

Base station energy storage lithium battery principle diagram

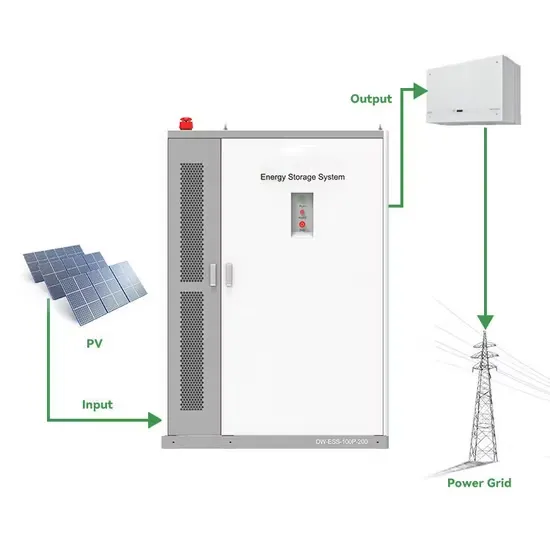

Download scientific diagram | Schematic diagram of a battery energy storage system operation. from publication: Overview of current development in electrical energy storage technologies

Get a quote

The Reason for Shortening the Service Life of Base Station

According to the current battery manufacturer''s anatomy of the battery at the base station, the end of battery life is caused by the sulfate of the battery negative plate This is a

Get a quote

Working principle of battery pack in base station

Battery energy storage systems (ESS) have been widely used in mobile base stations (BS) as the main backup power source. Due to the large number of base stations,

Get a quote

Understanding Backup Battery Requirements for Telecom Base Stations

Telecom base stations require reliable backup power to ensure uninterrupted communication services. Selecting the right backup battery is crucial for network stability and

Get a quote

Design of base station battery pack

Can a stepped battery be used in a communication base station backup power system? In view of the characteristics of the base station backup power system, this paper proposes a design

Get a quote

Discussion Forums

Hello-? anyone running the base in a base-rover setup with an external battery? We need to now run 2 bases. We have a battery that we purchased from our survey equipment

Get a quote

Telecom Battery Backup System | Sunwoda Energy

A telecom battery backup system is a comprehensive portfolio of energy storage batteries used as backup power for base stations to ensure a reliable and stable power supply. As we are

Get a quote

Base Station Battery Module 51.2V 100Ah 5.12kWh

Base Station Battery Module 51.2V 100Ah 5.12kWh. Lithium Iron Phosphate can be used in most applicatio that use Lead Acid, GEL or AGM type batteries.

Get a quote

How the Base battery works: A complete guide to grid

When the grid goes down, the battery hub separates your house from the grid and all the energy in the battery goes to power your home. When the grid is

Get a quote

How the Base battery works: A complete guide to grid

When the grid goes down, the battery hub separates your house from the grid and all the energy in the battery goes to power your home. When the grid is working and chances of outages are

Get a quote

Telecom Base Station Backup Power Solution: Design Guide for

This guide outlines the design considerations for a 48V 100Ah LiFePO4 battery pack, highlighting its technical advantages, key design elements, and applications in telecom

Get a quote

Mobile Base Station Energy Storage Principle: How It Keeps You

Enter liquid-cooled battery cabinets and phase-change materials that absorb heat like a digital ice pack. Huawei''s latest 5G stations use "battery hibernation" tech, extending

Get a quote

Mobile Base Station Energy Storage Principle: How It Keeps You

Meet the unsung hero of modern connectivity – mobile base station energy storage systems. These technological marvels work like giant power banks for cell towers, ensuring

Get a quote

How about base station energy storage batteries

One significant aspect of these batteries is their ability to improve grid resilience, which is crucial in areas prone to power interruptions. This

Get a quote

Mechanical Design of Battery Packs

This lesson covers the mechanical design of battery packs, starting with a review of the electrical design and the issues that can arise. The lesson also explains the calculation of capacity,

Get a quote

4.8kWh Base Station Battery 48V 100Ah LiFePO4

Battery Type: 51.2V 100Ah LiFePO4 Battery Pack Nominal Voltage: 51.2V Nominal Capacity: 100Ah Dimension: 530x440x132mm Weight: 46kg Battery

Get a quote

6 FAQs about [Base station battery pack current principle]

What makes a telecom battery pack compatible with a base station?

Compatibility and Installation Voltage Compatibility: 48V is the standard voltage for telecom base stations, so the battery pack’s output voltage must align with base station equipment requirements. Modular Design: A modular structure simplifies installation, maintenance, and scalability.

What is battery pack design?

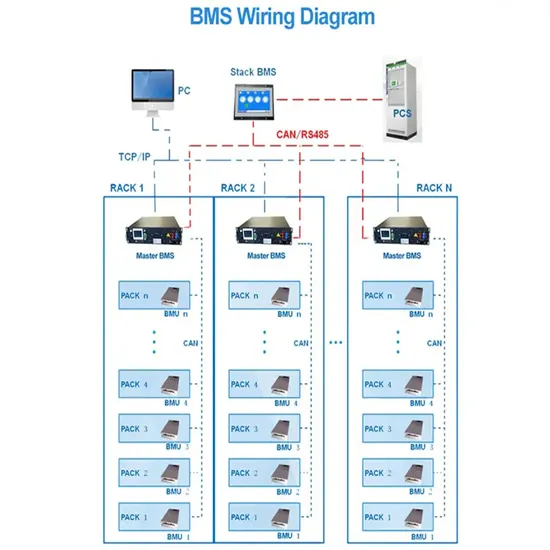

Battery pack design involves considering electrical, mechanical, thermal aspects and the Battery Management System (BMS). - Mechanical design considerations include the weight of the battery, the forces acting on it, and the material selection for the base plate.

What is a base battery system?

The Base battery system is built for performance and reliability. It combines a high-capacity lithium iron battery with intelligent software to optimize energy use. The Base battery system has three main components: the battery pack, inverter, and hub. The long white unit is the battery pack. We mount the battery pack on the ground.

How does a base battery work?

This process is called grid-balancing. Base batteries deploy energy to the grid faster than any other service, which is how Base is able to recoup the cost of the battery equipment and keep prices low for homeowners. The charge level of your Base battery will naturally fluctuate over time, rising and falling throughout a multi-day cycle.

Which battery is best for telecom base station backup power?

Among various battery technologies, Lithium Iron Phosphate (LiFePO4) batteries stand out as the ideal choice for telecom base station backup power due to their high safety, long lifespan, and excellent thermal stability.

What types of forces affect a battery pack?

Different types of forces, including compressive, tensile, shear, torsion, and bending forces, can act on the battery pack. Discover the process of designing battery packs, including electrical and mechanical considerations, using the example of an electric bike.

Guess what you want to know

-

Estonian communication base station battery pack

Estonian communication base station battery pack

-

Lithium battery pack outer box container base station

Lithium battery pack outer box container base station

-

China Unicom base station lead-acid battery pack

China Unicom base station lead-acid battery pack

-

Base station battery pack specifications

Base station battery pack specifications

-

Base station battery output current

Base station battery output current

-

Base station battery pack ESS power base station

Base station battery pack ESS power base station

-

Congo Kinshasa communication base station battery pack

Congo Kinshasa communication base station battery pack

-

The total voltage of the base station battery pack is too high

The total voltage of the base station battery pack is too high

-

2V battery pack in base station room

2V battery pack in base station room

-

What is the capacity of the communication base station battery pack

What is the capacity of the communication base station battery pack

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.