Innovative CdTe Solar Technology: Transparent

The CdTe (Cadmium Telluride) solar panel is an important branch of thin-film solar technology. Some of its advantages compared to traditional c

Get a quote

Solar Panel Thickness: What You Need to Know

Learn how solar panel thickness impacts performance, durability, and cost. This article offers insights to help you make the best purchase decision.

Get a quote

Solar Panel Thickness

Solar cells are generally the thickest component of a solar panel, and their thickness can vary from about 200 micrometers (0.2mm) to 400 micrometers (0.4mm). The

Get a quote

Solar Panel Thickness: What You Need to Know Before Buying

Learn how solar panel thickness impacts performance, durability, and cost. This article offers insights to help you make the best purchase decision.

Get a quote

How Thick Are Solar Panels? Solar Panel Size Explained

Most traditional solar panels measure between 30mm and 40mm (1.18 to 1.57 inches) thick. This thickness is typical for models that use

Get a quote

Standard Solar Panel Sizes And Wattages (100W-500W

The only useful thing that we get from this is depth or height (panel thickness): Most solar panels are about 1.5 inches thick. Alright, let''s have a look at the length and width of typical solar

Get a quote

What is the appropriate thickness of solar panels?

To delve into the concept of solar panel thickness, it''s vital to consider the myriad of factors influencing this characteristic, including material

Get a quote

Solar Glass: applications and comparison to Light-Trapping

To ensure high solar energy transmittance, glass with low iron oxide is typically used in solar panel manufacturing. Strength Solar panels are made of tempered glass, which is sometimes

Get a quote

Microsoft Word

Typical solar panels (honeycomb substrate) with multijunction cells can achieve a specific power of 150 W/kg and a power density of 350 W/m2 depending on the exact solar panel design.

Get a quote

How Thick Are Solar Panels? Solar Panel Size Explained

Most traditional solar panels measure between 30mm and 40mm (1.18 to 1.57 inches) thick. This thickness is typical for models that use crystalline silicon cells. New

Get a quote

Why are solar panels so thick? | NenPower

Solar panel thickness significantly impacts cost due to materials, technology, and overall manufacturing practices. Thicker panels often utilize higher-quality components that

Get a quote

Monocrystalline silicon solar panel thickness standard table

Solar photovoltaic (PV) panels are a vital component of the global transition towards renewable energy sources and the development of PV technologies such as monocrystalline and

Get a quote

Solar Photovoltaic Panel Sizes [Full List And Other FAQs]

Most residential solar panel dimensions are standardised to around 60 cells and are roughly 65 by 39 inches in size dimensions, with a thickness of around 1.5 inches.

Get a quote

Solar Photovoltaic Panel Sizes [Full List And Other

Most residential solar panel dimensions are standardised to around 60 cells and are roughly 65 by 39 inches in size dimensions, with a thickness of around 1.5

Get a quote

Solar Panel Dimensions and Sizes: Complete Guide

Standard Solar Panel Size How big is a solar panel? There are three main sizes of solar panels to know: 60-cell, 72-cell, and 96-cell. For commercial and

Get a quote

Innovators of Solar Components | Commitment to Excellence

Encapsulant solar panel sheet is copolymer resin used to encapsulate solar cells. It protects the cell from jerks and shocks, thus increasing the life of solar cells by preventing oxygen and

Get a quote

Design Considerations for a Spacecraft Solar Array

Fitting the solar cell datasheet parameters to an empirical equation for photovoltaic cells resulted in the following IV-curves. Top row: Triple

Get a quote

What is the appropriate thickness of solar panels? | NenPower

To delve into the concept of solar panel thickness, it''s vital to consider the myriad of factors influencing this characteristic, including material composition, manufacturing

Get a quote

How Solar Panel Thickness Affects Durability: What You Need to

Discover how solar panel thickness impacts durability and performance. Learn why thicker panels resist environmental stress better, withstand harsh conditions, and offer longer lifespans.

Get a quote

How Thick Are Solar Panels? [Updated: September 2025]

A solar panel is made up of many thin, flexible, and lightweight photovoltaic cells. Each cell is only around 1 micron thick, which is less than one thousandth of a millimeter.

Get a quote

Solar Glass

The Most Comprehensive Selected Top Class Chinese Glass Machines, Products and Services Resource Glass Fabricating Machines | Glass Processing Machines | Glass Furnaces | Glass

Get a quote

Standard Solar Panel Sizes And Wattages (100W

The only useful thing that we get from this is depth or height (panel thickness): Most solar panels are about 1.5 inches thick. Alright, let''s have a look at the

Get a quote

The structure of a photovoltaic module

The latter is the main parameter affecting the power output of the panel. In this period the most common cells are the polycrystalline ones with an efficiency of about 17.6%, which originate a

Get a quote

Guess what you want to know

-

Can photovoltaic panel cells be replaced

Can photovoltaic panel cells be replaced

-

Portugal non-standard BIPV solar panel components photovoltaic cells

Portugal non-standard BIPV solar panel components photovoltaic cells

-

Peru monocrystalline photovoltaic panel general contracting

Peru monocrystalline photovoltaic panel general contracting

-

Moldova small photovoltaic panel BESS price

Moldova small photovoltaic panel BESS price

-

Photovoltaic module solar panel companies

Photovoltaic module solar panel companies

-

Norwegian monocrystalline silicon photovoltaic panel manufacturer

Norwegian monocrystalline silicon photovoltaic panel manufacturer

-

Photovoltaic station solar panel curtain wall

Photovoltaic station solar panel curtain wall

-

What is the appropriate thickness of photovoltaic solar panels

What is the appropriate thickness of photovoltaic solar panels

-

Photovoltaic panel power generation per kilowatt

Photovoltaic panel power generation per kilowatt

-

Costa Rican home photovoltaic panel prices

Costa Rican home photovoltaic panel prices

Industrial & Commercial Energy Storage Market Growth

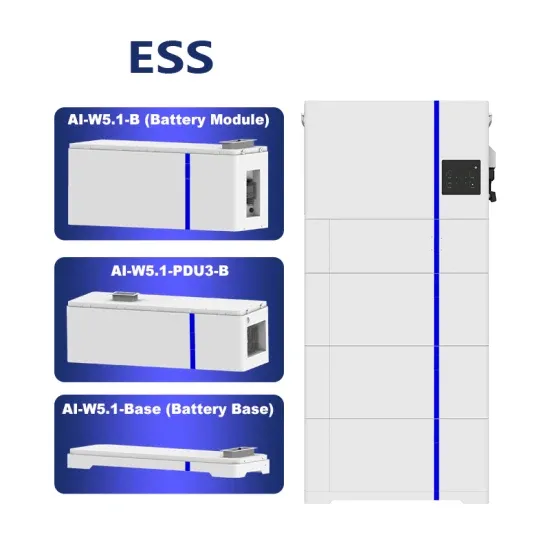

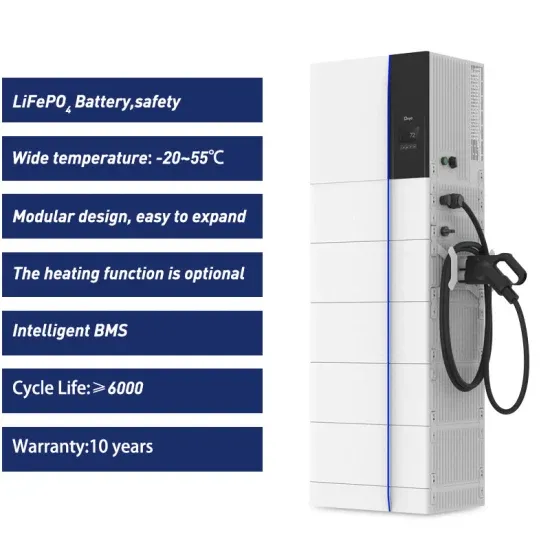

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.