PLC BASED SOLAR TRACKING SYSTEM

The target of this project was to establish a solar tracking system with programmable logic controller as its controlling unit. More specifically this project concerned the programming of

Get a quote

Dual Axis Solar Tracking System Basics: Dual Axis

A dual-axis solar tracking system has motors to rotate the solar panels around vertical and horizontal axes, allowing them to follow the sun''s

Get a quote

Solar Tracking System: Working, Types, Pros, and Cons

Other elements include PV cells, PLC, signal processing units, sensors, electromagnetic, and mechanical motion control modules, along with

Get a quote

Design and Implementation of a Two Axis Solar Tracking System Using PLC

The designed tracking system consists of four sensors (LDR) and a programmable logic controller (PLC) which controls two DC servomotors with control software designed for

Get a quote

Solar Tracking System: Working, Types, Pros, and Cons

Other elements include PV cells, PLC, signal processing units, sensors, electromagnetic, and mechanical motion control modules, along with power supply systems.

Get a quote

7 Things to Know About PLCs for Solar PV Projects

We typically recommend using a dedicated hardware PLC like the GE, Ovation or Allen-Bradley when an RTAC doesn''t completely fill the advanced control requirements, or when you need

Get a quote

Design and Implementation of a Two Axis Solar

The designed tracking system consists of four sensors (LDR) and a programmable logic controller (PLC) which controls two DC servomotors with

Get a quote

Two axes sun tracking system with PLC control

Single axis tracking systems are considerably cheaper and easier to construct, but their efficiency is lower than that of two axes sun tracking systems. On the other hand, some

Get a quote

Dual Axis Solar tracking System using PLC

Precise control of the stepper motors is possible by using the PLC. By giving a suitable delay between each step, the time for rotation of the solar panel to a particular position can also be

Get a quote

Automatic Solar Tracking System Using Siemens PLC

This research paper presents the design, implementation, and performance evaluation of a single-axis solar tracking system (SASTS) employing Siemens programmable

Get a quote

Advantages and disadvantages of automatic solar

Benefits: The benefits of solar tracker are provided below:. Solar tracking systems are utilized to continually orient photovoltaic panels to the

Get a quote

AC500

The PLC AC500 guarantees that the requirements of your automation technology are met despite ever-changing conditions and regardless of the location and of the solar-tracking concepts used

Get a quote

AUTOMATIC SOLAR TRACKING SYSTEM USING PLC & SCADA

The controller used is Programmable Logic Controller (PLC). Speed and direction of the motor is controlled by the V/f Drive. The tacking is done by programmed Time-Delayed

Get a quote

Design of Single Axis Solar Tracking System Using PLC

The objective of this paper is to develop an automatic solar tracking system where solar panels will keep aligned with the Sunlight in order to maximize in harvesting solar power.

Get a quote

Solar tracking control system based on PLC

inverter for the photovoltaic systems tracking system was used, 220V (AC) could be taken directly from the photovoltaic inverter power. Fig. 4: Power Supply Unit PLC control and monitoring

Get a quote

Review on sun tracking technology in solar PV system

This paper begins with a brief introduction to the solar PV cells and the materials used in their construction. It also discusses the types of solar PV systems and types of solar

Get a quote

Solar Tracking System using Delta PLC

The PLC control statements were the important constituent of the entire solar panel tracking system, and the software programming was done using ladder logic coding and was written in

Get a quote

What is a solar tracker? Advantages and disadvantages

A photovoltaic solar tracker is a mechanical device to rotate PV panels to achieve an optimal angle concerning the sun''s rays. The greater the

Get a quote

Siemens S7-1200 PLC solar tracking controller linked

The solar energy resource can be tapped into for rural social upliftment, should a suitable and reliable solar power generation system be available. With limited

Get a quote

Assessment of solar tracking systems: A comprehensive review

Abstract Implementing solar tracking systems is a crucial approach to enhance solar panel efficiency amid the energy crisis and renewable energy transition. This article

Get a quote

Sun-Tracking System with PLC Control for Photo-Voltaic Panels

Abstract In this study, the electromechanical control system of a photovoltaic (PV) panel tracking the sun on the axis it moves along according to its azimuthal angle was

Get a quote

Solar trackers: everything you need to know

A solar tracker system helps maximize your solar production by following the sun throughout the day. Solar trackers are usually reserved for large-scale ground mounted solar

Get a quote

PLC Based Solar Tracking System

The circuit and the mechanism explained in this article may be considered as the easiest and perfect dual axis solar tracker system.The device is able to track the daytime motion of the sun

Get a quote

7 Things to Know About PLCs for Solar PV Projects

The controller used is Programmable Logic Controller (PLC). Speed and direction of the motor is controlled by the V/f Drive. The tacking is done by

Get a quote

6 FAQs about [Does a solar tracking system require a PLC ]

How does a solar tracking system work?

The designed tracking system consists of four sensors (LDR) and a programmable logic controller (PLC) which controls two DC servomotors with control software designed for this purpose to move the system panel according to the information from the input sensors, keeping the panel always perpendicular to sun rays.

Can a PLC measure solar energy?

A PLC type s7-200 from Siemens, a Human Machine Interface (HMI), an analog extension module (EM) , a temperature sensor type Pt100 and an inexpensive system for measuring solar radiation and applications of solar energy [8, 9,10] were used in this simulation.

Why should you use Siemens plc for automatic solar tracking?

CPU and the programming tools allow users to design autonomous industrial processes and solve automation problems. Based on this specific application and its user-friendly programming tool and troubleshooting solutions, Siemens’ PLC hardware and software were found to be the right fit for the automatic solar tracking application in this project.

How accurate is solar tracking?

When in range, the system has a tracking accuracy of ±1°. Data analysis from research shows that even a single axis three-position system can increase efficiency and make solar tracking a worthwhile endeavour. Automated tracking, Linear motors, PLC, Solar tracking, Solar panels.

How to choose a solar tracker?

You need to consider factors like climate, space, and shading before deciding on solar tracking. These tracking systems offer the most benefits in locations with high latitudes due to the sun’s yearly movements. In conclusion, positioning a solar tracker directs the solar panels at an angle toward the sun.

What are the applications of solar tracking system?

The main application of solar tracking system is to position solar photovoltaic (PV) panels towards the Sun. Most commonly they are used with mirrors to redirect sunlight on the panels. Cross-Reference: Design and Implementation of High Efficiency Tracking System

Guess what you want to know

-

How many watts does a solar all-in-one machine usually require

How many watts does a solar all-in-one machine usually require

-

How many watts do outdoor solar panels require

How many watts do outdoor solar panels require

-

Sri Lanka Solar Tracking System

Sri Lanka Solar Tracking System

-

Southern Europe Solar Tracking System

Southern Europe Solar Tracking System

-

Solar automatic tracking lithium battery charging system

Solar automatic tracking lithium battery charging system

-

Solar tracking system returns

Solar tracking system returns

-

Design of automatic tracking system for solar panels

Design of automatic tracking system for solar panels

-

Solar photovoltaic panels require no installation

Solar photovoltaic panels require no installation

-

Solar tracking system power generation efficiency

Solar tracking system power generation efficiency

-

Solar three-axis tracking system

Solar three-axis tracking system

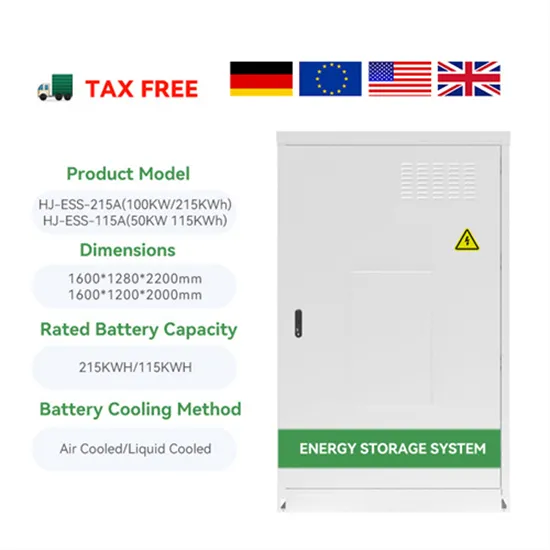

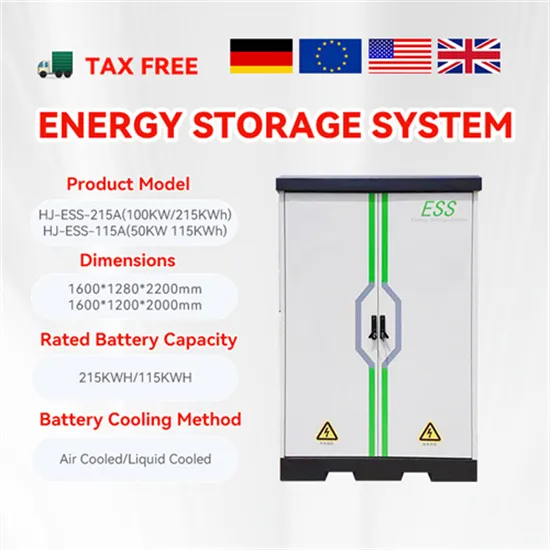

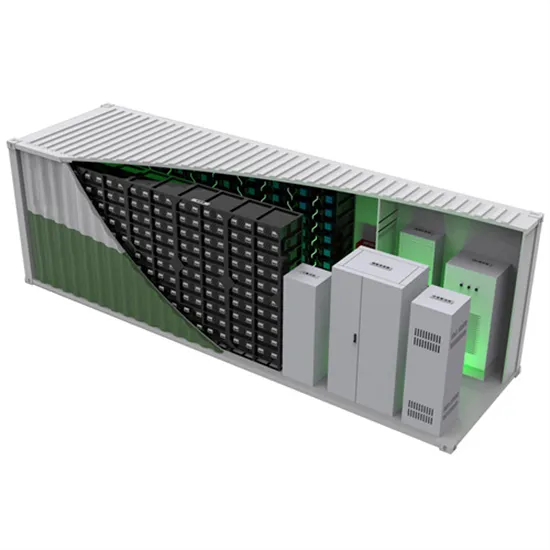

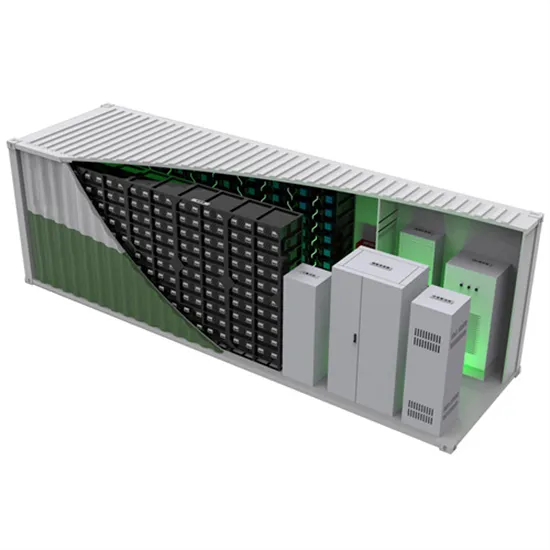

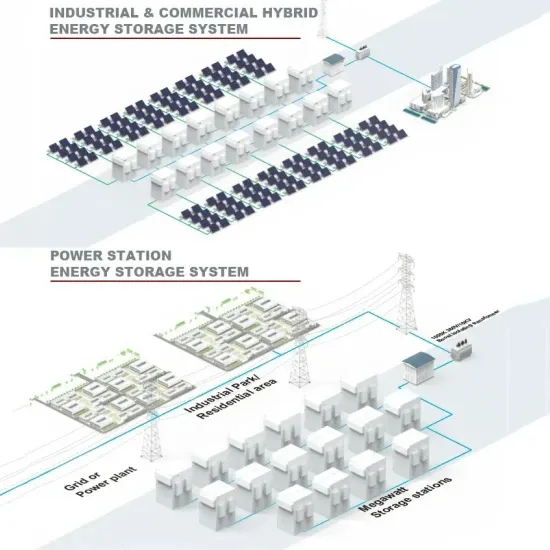

Industrial & Commercial Energy Storage Market Growth

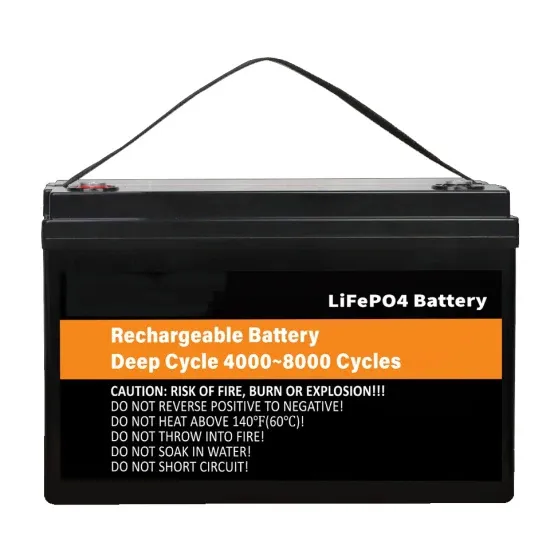

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

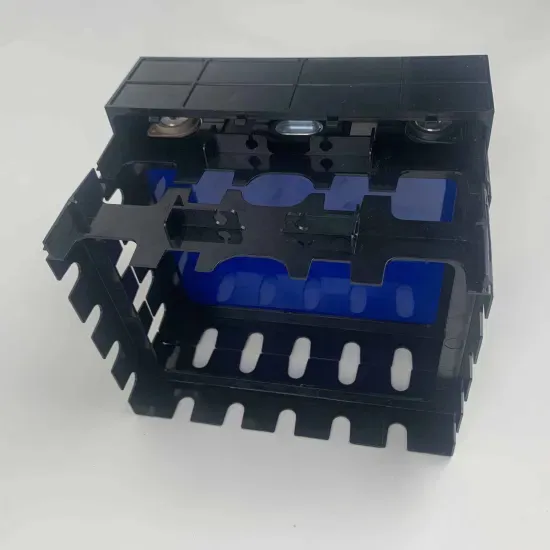

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.