Internal Corrosion and Delamination in Solar Panels:

Internal corrosion, or rusting of the panels, happens when moisture seeps inside the system. There must be no air, nor water, that gets inside

Get a quote

Photovoltaic Standards

Standards from this category regulate solar cells (modules) characteristic measurement, solar cells (modules) tests and other standards referring to solar cells

Get a quote

Review of degradation and failure phenomena in photovoltaic modules

The degradation of photovoltaic (PV) systems is one of the key factors to address in order to reduce the cost of the electricity produced by increasing the operational lifetime of PV

Get a quote

IEC 61701:2020 | IEC Webstore

IEC 61701:2020 describes test sequences useful to determine the resistance of different PV modules to corrosion from salt mist containing Cl (NaCl, MgCl2,

Get a quote

TOPCon & HJT Solar Technology: Quality Risks and

Understand the quality control risks, failure modes, and solar panel testing challenges in TOPCon and HJT solar tech for long-term

Get a quote

Understanding Photovoltaic Module Degradation: An Overview of

Abstract Photovoltaic (PV) modules, though reputed for reliability and long lifespans of 25-30 years, commonly experience gradual performance degradation influenced

Get a quote

Internal Corrosion and Delamination in Solar Panels: What You

Internal corrosion, or rusting of the panels, happens when moisture seeps inside the system. There must be no air, nor water, that gets inside each module, or some serious

Get a quote

What are the corrosion hazards of solar panels? | NenPower

The presence of moisture, salt, and pollutants can initiate and accelerate corrosion, leading to various hazards affecting both the performance and the durability of solar

Get a quote

PV Module Corrosion Testing | TÜV Rheinland

Comprehensive corrosion testing of PV modules according to international standards to ensure claimed output and correct labeling. Find out more here.

Get a quote

Corrosion testing of solar cells: Wear-out degradation behavior

There are a variety of components in PV cells and modules that may be susceptible to corrosion, including solar cell passivation, metallization, and interconnection.

Get a quote

Electrochemical Mechanisms of Leakage-Current in

The system voltage of solar panels drives a leakage current between the solar cells and the grounded metal frames. This results in many different forms of potential induced degradation,

Get a quote

Corrosion testing of solar cells: Insights to wear-out mechanisms

Corrosion is a major end-of-life degradation mode in photovoltaic modules. Herein, an accelerated corrosion test for screening new cell, metallization, and interconnection

Get a quote

Corrosion in solar cells: challenges and solutions for enhanced

Corrosion in solar cells can significantly impact their efficiency, reliability, and overall performance. Firstly, corrosion can cause the degradation of key components such as

Get a quote

Managing and Mitigating Solar PV Corrosion

The following three types of corrosion are most commonly seen in solar PV systems. Understanding these types helps agencies better plan for corrosion-resistant design and

Get a quote

Acetic Acid Production Rate in EVA Encapsulant and

The document discusses the impact of acetic acid production in EVA encapsulants on the reliability of photovoltaic (PV) modules, highlighting the

Get a quote

Electrochemical mechanisms of leakage-current-enhanced delamination and

This paper analyzes the mechanisms for corrosion and delamination observed in Si photovoltaic modules subjected to high temperature and humidity with a negative-ground

Get a quote

Degradation and Failure Mechanisms of PV Module Interconnects

This chapter reviews the major reliability issue of PV module interconnects, including the PV cells screen printed silver busbar and grid line corrosion, solder joint degradation, and

Get a quote

Photovoltaic support anti-corrosion standards

There are a variety of components in PV cells and modules that may be susceptible to corrosion, including solar cell passivation, metallization, and interconnection.

Get a quote

Solar Panel Corrosion: A Review

This review emphasizes the importance of corrosion management for sustainable PV systems and proposes future research directions for developing more durable materials

Get a quote

Corrosion in solar cells: challenges and solutions for

Abstract Corrosion is a critical issue that can significantly impact the performance and lifespan of solar cells, afecting their eficiency and reliability. Understanding the complex relationship

Get a quote

Mitigation of Corrosion in Solar Panels with Solar

Corrosion in solar panels represents a significant challenge that can negatively impact their performance, durability and profitability. Therefore,

Get a quote

Ammonia Corrosion in Solar Panels for Farms & Agri

Discover how ammonia exposure damages PV modules in agricultural settings. Why IEC 62716 is important are vital for farms and

Get a quote

A Novel Accelerated Corrosion Test for Supporting Devices

Abstract: Recently, countries from around the globe have been actively developing a new solar power system, namely, the floating photovoltaic (FPV) system. FPV is advantageous in terms

Get a quote

Mitigation of Corrosion in Solar Panels with Solar Panel Materials

Corrosion in solar panels represents a significant challenge that can negatively impact their performance, durability and profitability. Therefore, it is critical to develop

Get a quote

Guess what you want to know

-

Nicaragua solar panel photovoltaic module manufacturer

Nicaragua solar panel photovoltaic module manufacturer

-

Canada Solar Panel Photovoltaic Module Sales

Canada Solar Panel Photovoltaic Module Sales

-

Nicaragua solar panel photovoltaic module seller

Nicaragua solar panel photovoltaic module seller

-

Which solar panel and photovoltaic module manufacturer is best in Guinea

Which solar panel and photovoltaic module manufacturer is best in Guinea

-

Indian solar photovoltaic panel manufacturers

Indian solar photovoltaic panel manufacturers

-

Photovoltaic hidden frame solar panel curtain wall

Photovoltaic hidden frame solar panel curtain wall

-

Senegal solar photovoltaic module manufacturer

Senegal solar photovoltaic module manufacturer

-

Niue photovoltaic panel greenhouse solar energy

Niue photovoltaic panel greenhouse solar energy

-

20w monocrystalline silicon photovoltaic solar panel

20w monocrystalline silicon photovoltaic solar panel

-

Western European Photovoltaic Solar Panel Factory

Western European Photovoltaic Solar Panel Factory

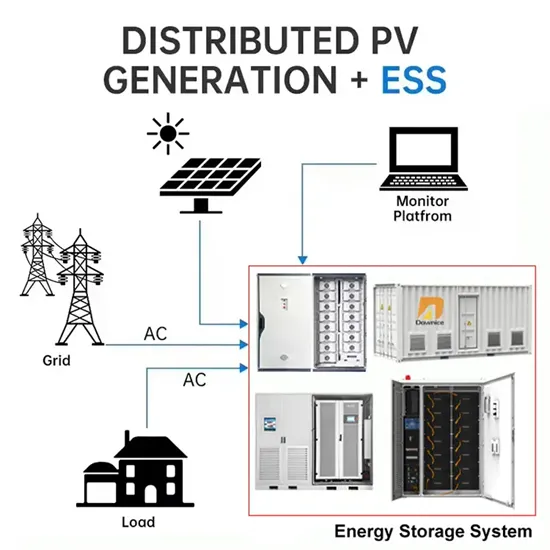

Industrial & Commercial Energy Storage Market Growth

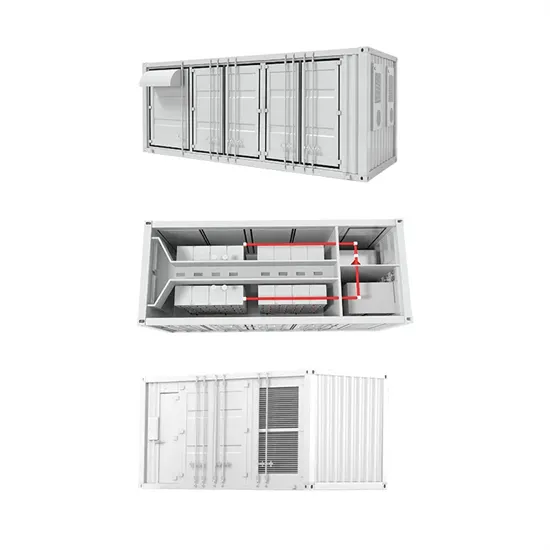

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

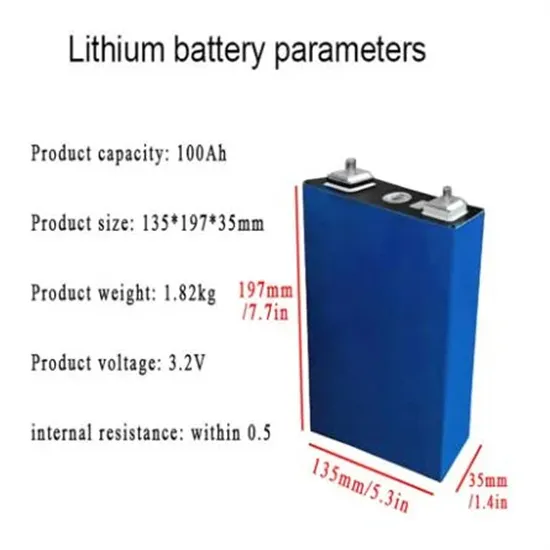

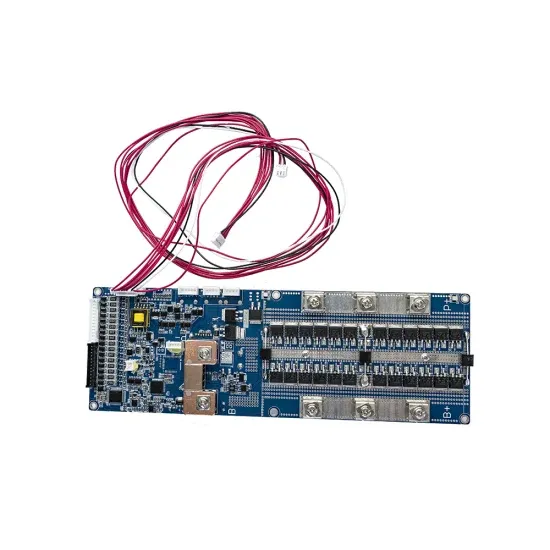

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.