Eaton 93PM Integrated Battery Cabinet-Small Welded

The battery detect signal wiring from the battery cabinet must be connected to a programmed UPS building alarm in the 93PM (480V) UPS and to CN8 in the 93PM-L (208V) UPS [CN8 is a

Get a quote

Powerware 9390 Integrated Battery Cabinet (Models IBC-S and

Chapter 1, Introduction provides a brief description of the battery system, adescription of the content of each chapter, text conventions used in the manual, safetywarnings, and reference

Get a quote

Galaxy Lithium-ion Battery Cabinet

Only for installing the battery cabinet in a new location: Follow the installation manual to install the battery cabinet in the new location. See Installation Procedure, page 18 for installation overview.

Get a quote

USER MANUAL BATTERY CABINET

Before installing batteries into the cabinet, carefully remove all items from inside the cabinet and lay it on its back, preferably on a clean surface or a furniture blanket.

Get a quote

Battery Racks and Battery Charger Installation

Battery Racks and Battery Charger Installation This article is for installation of vented lead acid batteries, battery racks and battery chargers in dedicated battery rooms for main substations,

Get a quote

UPS Battery Cabinets

Introduction This manual contains information intended to help owners and operators understand how to safely and properly prepare, install, and operate ZincFive batteries. To ensure

Get a quote

UPS Installation Guide-Custom Lithium ion Battery

ups unpacking, battery unpacking for backup, When assembling the battery cabinet, pay attention not to touch the positive and negative poles

Get a quote

Mitsubishi Electric Power Products, Inc. UBC64 Battery

Install the main POS and NEG cables from the output circuit breaker to the correct battery posts on the designated battery units shown in the provided battery system schematic.

Get a quote

BC58 Battery Cabinet Installation, Operation, & Maintenance

Battery cabinets that are not supplied with an incorporated DC output disconnect device must have an appropriate disconnect device provided external to the cabinet.

Get a quote

-48 VDC Battery Cabinet Installation and User Manual

Procedure Refer to Figure 3 and install the 19" or 23" relay rack mounting angles to the battery cabinet. Mounting hardware is provided with the battery cabinet. Torque these connections to

Get a quote

P-164000302_93E_60_UPS Gn 3 Rev2-Rel.book

The battery types listed in Figure 3-10 are supplied in the UPS Cabinet and external Battery Cabinet. When purchasing UPS Cabinet or external Battery Cabinet without batteries, only the

Get a quote

NetSure™ 211 Series -48 VDC Battery Cabin

Connect the second battery cabinet''s battery cable terminated in an Anderson connector to the fixed mating Anderson connector located on the first battery cabinet.

Get a quote

The BESS System: Construction, Commissioning, and

The guide is divided into three main sections: construction and installation, commissioning, and operation & maintenance. It covers various aspects such

Get a quote

UBC80 Battery Cabinet Installation, Operation,

Whether the Battery Cabinet is empty or partially assembled, it should be located, mounted and properly grounded prior to final assembly as instructed in this manual in sections 6.2.1, 6.2.2

Get a quote

Eaton 93E External Battery Cabinet installation manual

Read all instructions before operating the equipment and save this manual for future reference. Ce manuel comporte des instructions importantes que vous êtes invité à suivre lors de toute

Get a quote

Simple installation manual of DC cabinet

Post installation inspection The energy storage system shall be inspected after installation: Tighten the screw, the torque meets requirement(12Nm); Wiring from the high voltage box of

Get a quote

Battery Cabinet

Install the Battery Cabinet following local building requirements and applicable codes. Plan the location of the Battery Cabinet site ahead of time, taking into consideration the requirements

Get a quote

Powerware 9390 Integrated Battery Cabinet (Models IBC-S

AChapter 2, "Battery Cabinet Installation Plan and Unpacking" – explains how to prepare the site for the installation of the battery cabinet. It discusses equipment environmental requirements,

Get a quote

Evolve ESS Installation Manual

This manual contains instructions for the installation and start up sequence of the Eguana EvolveTM ESS; including the PCS and master battery cabinets. This product is permanently

Get a quote

Schneider Electric Easy UPS 3S Modular Battery

Expert UPS advice at Secure Power. E3SXR6 Schneider Easy UPS 3S Modular Battery Cabinet. Easy to install, use, and service for small to medium data

Get a quote

Eaton 93PM Integrated Battery Cabinet-Large and Large

This manual contains important instructions that should be followed during installation and maintenance of the UPS and batteries. Read all instructions before operating the equipment

Get a quote

6 FAQs about [Battery cabinet installation sequence]

Where do I install a line-up and match Battery Cabinet?

Line-up-and-match battery cabinets are installed adjacent to the UPS. The recommended installation location is on the right side of the UPS cabinet as viewed from the front of the cabinet. See Figure 3 for line-up-and-match configuration views. Figure 3. Eaton 93PM 100 kW UPS and Two 93PM Integrated Battery Cabinets

Where is the battery cabinet located?

The battery cabinet may be located to either the right or left of the UPS cabinet. The recommended location is to the right of the UPS cabinet. This procedure assumes the battery cabinet is located to the right of the UPS cabinet. 21.

How many IBCs can be installed in a 93pm integrated battery cabinet?

Standalone IBC installations with three or four IBCs require a customer supplied external tie point and circuit breaker or disconnect between the IBCs and the UPS. Up to four IBCs can be installed in a standalone configuration. Use this procedure to wire standalone 93PM Integrated Battery Cabinets to the 93PM UPS cabinet.

Where is the UPS battery cabinet located?

The recommended location is to the right of the UPS cabinet. This procedure assumes the battery cabinet is located to the right of the UPS cabinet. 21. If line-up-and-match installation, remove the rectangular knockout on the bottom front side of the UPS and the IBC (see Figure 15).

What is an integrated battery cabinet (IBC)?

The Integrated Battery Cabinet (IBC) is available in two model to meet the needs of the Eaton 93PM UPS product line. UPS. IBC-L output protected by 300A circuit breaker. IBC-LH output protected by 500A circuit breaker. The recharge date is also stated on a label inside the IBC.

How is a ups connected to a battery cabinet?

In standalone configurations power wiring is routed using external conduit. Connections are made to easily accessible terminals at the back of the cabinet. Line-up-and-match battery cabinets are installed adjacent to the UPS.

Guess what you want to know

-

Battery cabinet installation interface cost price

Battery cabinet installation interface cost price

-

Energy storage cabinet battery liquid cooling installation site

Energy storage cabinet battery liquid cooling installation site

-

Albania lithium battery energy storage cabinet installation factory is running

Albania lithium battery energy storage cabinet installation factory is running

-

Photovoltaic communication battery energy storage cabinet installation site

Photovoltaic communication battery energy storage cabinet installation site

-

Outdoor air-cooled battery cabinet installation site

Outdoor air-cooled battery cabinet installation site

-

Energy storage battery cabinet installation base station

Energy storage battery cabinet installation base station

-

Installation site of integrated battery cabinet

Installation site of integrated battery cabinet

-

Battery cabinet large battery installation

Battery cabinet large battery installation

-

Price query for outdoor communication battery cabinet installation in Brazil

Price query for outdoor communication battery cabinet installation in Brazil

-

Backup power battery cabinet installation

Backup power battery cabinet installation

Industrial & Commercial Energy Storage Market Growth

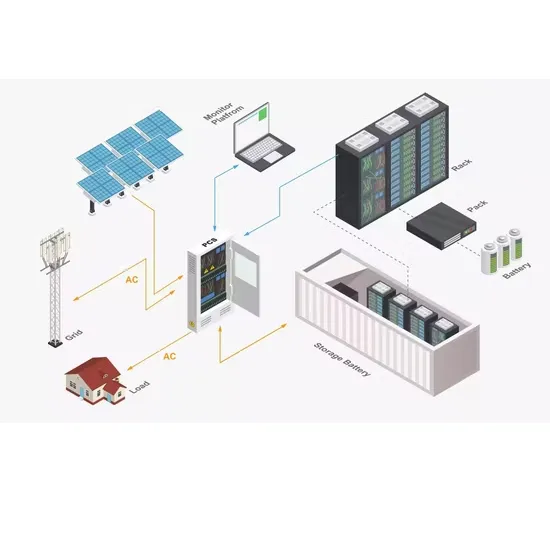

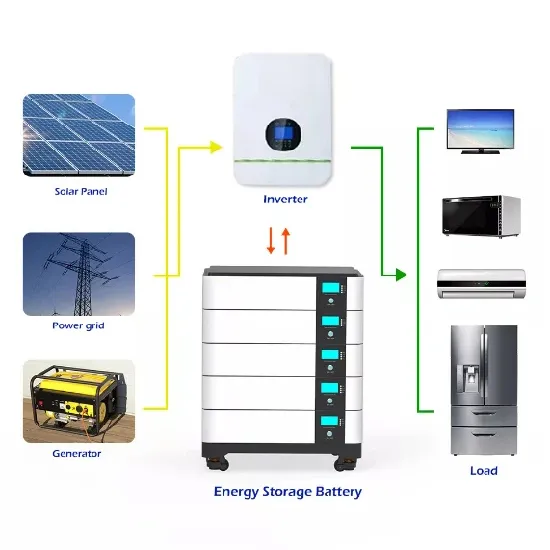

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.