Integrated Solar Modules: The Next Step in Solar Design

Over the past few years, there has been a push to make solar panels less intrusive, longer lasting, and more effective. As a result, integrated solar modules are arriving on the market and

Get a quote

Reliable Solar Panel Making Machine Supplier

Our fully automated production line is responsible for building each bespoke PV panel on a turnkey basis, automating the entire process from scribing,

Get a quote

Integrated Solar Panels Guide

Integrated solar panels are commonly known as in-roof solar panels. They are similar to conventional solar panels installed on top of slates or roof tiles, but these are integrated into

Get a quote

Hybrid prediction method for solar photovoltaic power

Liu, H., Cai, C., Li, P. et al. Hybrid prediction method for solar photovoltaic power generation using normal cloud parrot optimization algorithm integrated with extreme learning

Get a quote

What does solar integrated machine mean? | NenPower

These machines utilize solar panels to capture sunlight and convert it into usable electricity or thermal energy, depending on the application''s requirements. This integration

Get a quote

What machine is used to make solar panels?

The solar panel manufacturing ecosystem relies on a tightly integrated suite of machines, each optimized for precision, speed, and scalability. From laser scribing to final IV testing,

Get a quote

SOLAR/PV EQUIPMENT – Semiphoton

It is applicable to the continuous production of monocrystalline, polycrystalline, and amorphous solar/PV modules. Dual-level two sections of hot presses are used to reduce

Get a quote

What does solar integrated machine mean? | NenPower

A solar integrated machine signifies a device or system that incorporates solar technology into its design and functionality. 1. This means that solar energy directly powers its

Get a quote

Laminators for Solar PV Panels -ECOLAM SERIES

Looking for reliable laminators for solar panels? Discover Ecoprogetti''s ECOLAM SERIES, fully electric with advanced control systems for great lamination.

Get a quote

Boost Production Efficiency with Solar Panel Production Machines

Solar panel production machines are at the heart of the renewable energy revolution. By understanding the various types, applications, and technical features,

Get a quote

Building-integrated photovoltaics

The CIS Tower in Manchester, England was clad in PV panels at a cost of £5.5 million. It started feeding electricity to the National Grid in November 2005.

Get a quote

SOLAR/PV EQUIPMENT – Semiphoton

It is applicable to the continuous production of monocrystalline, polycrystalline, and amorphous solar/PV modules. Dual-level two sections of hot presses are used to reduce working time by

Get a quote

Clearline fusion Roof Integrated Solar PV

Roof Integrated solar PV As solar power moves beyond government subsidy to become a home improvement option, its kerb-appeal is becoming more and

Get a quote

Solar Panel Making Machines: A Guide to the Production

In this comprehensive guide, you will discover a fundamental overview of solar panel making machines and production processes essential for understanding solar panel

Get a quote

PV Module Stringer Machine | Solar Panel Soldering | Horad

MBB cell stringer machine is an automatic machine used for serial connection between crystalline silicon solar cells. The soldering machine can be used to connect 1/4, 1/3, half and full cells of

Get a quote

Machine learning in photovoltaic systems: A review

This paper presents a review of up-to-date Machine Learning (ML) techniques applied to photovoltaic (PV) systems, with a special focus on deep learning. It examines the

Get a quote

What is a solar integrated machine? | NenPower

A solar integrated machine represents a technological innovation that combines photovoltaic power generation with operational mechanisms designed for various applications.

Get a quote

Photovoltaic power generation solar integrated machine

Are solar PV systems ready to power a sustainable future? Real-time predictive capabilities and operational efficiency of solar PV systems can be investigated via the integration of real-time

Get a quote

Integrated Solar Panels Guide

Integrated solar panels are commonly known as in-roof solar panels. They are similar to conventional solar panels installed on top of slates or roof tiles, but

Get a quote

solar cell tabber stringer machine for photovoltaic

As a leading solar cell tabber stringer machine and used stringing machine supplier, we provice new solar panel production lines and refurbished/used

Get a quote

Integrated Solar Modules: The Next Step in Solar Design & Technology

Over the past few years, there has been a push to make solar panels less intrusive, longer lasting, and more effective. As a result, integrated solar modules are arriving on the market and

Get a quote

A comprehensive review on the recycling technology of silicon

With the aim of realizing the goals of the Paris Agreement, annual solar power generation on a global scale using silicon PV panels had exceeded 1000 TWh by the end of

Get a quote

6 FAQs about [Solar integrated machine solar photovoltaic panels]

What is solar inverter based generation?

As more solar systems are added to the grid, more inverters are being connected to the grid than ever before. Inverter-based generation can produce energy at any frequency and does not have the same inertial properties as steam-based generation, because there is no turbine involved.

How are solar panels made?

These lines consist of several machines working together to produce solar panels from start to finish. The use of robots and artificial intelligence in solar panel production is also on the rise and will play a big role in further reducing costs and improving efficiency for manufacturers.

What equipment is required to produce solar/PV modules?

Our automated Solar/PV modules production line includes a complete set of equipment, such as solar cells laser cutting, string soldering, welding, glass loading, layup, laminating, framing, J-Box soldering, curing, final testing, labeling, sorting, and packaging of the produced modules.

How do solar inverters work?

In a large-scale utility plant or mid-scale community solar project, every solar panel might be attached to a single central inverter. String inverters connect a set of panels—a string—to one inverter. That inverter converts the power produced by the entire string to AC.

What is a solar module test machine used for?

The Automatic IV Tester is used for a module power test. The electroluminescence (EL) tester is used for automatic defects detection after lamination, such as insufficient solder, hidden cracks, deviated welding, etc. The Automatic Labeling machine is used to print and accurately attach labels to a solar module.

What are the different types of solar inverters?

There are several types of inverters that might be installed as part of a solar system. In a large-scale utility plant or mid-scale community solar project, every solar panel might be attached to a single central inverter. String inverters connect a set of panels—a string—to one inverter.

Guess what you want to know

-

Installation of photovoltaic panels and solar integrated machine

Installation of photovoltaic panels and solar integrated machine

-

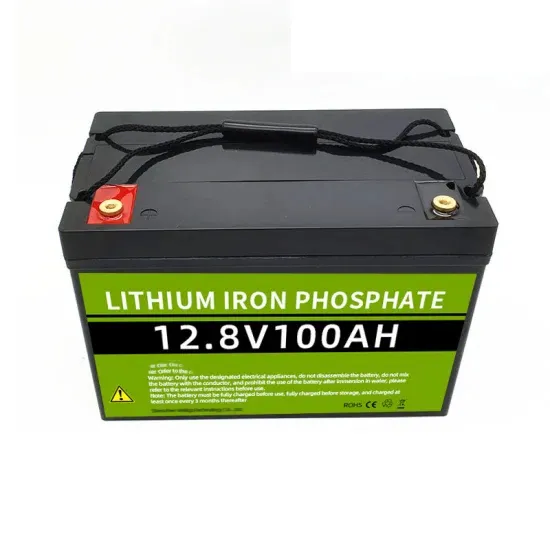

Solar integrated machine solar photovoltaic panels

Solar integrated machine solar photovoltaic panels

-

One-to-two photovoltaic panels solar integrated machine

One-to-two photovoltaic panels solar integrated machine

-

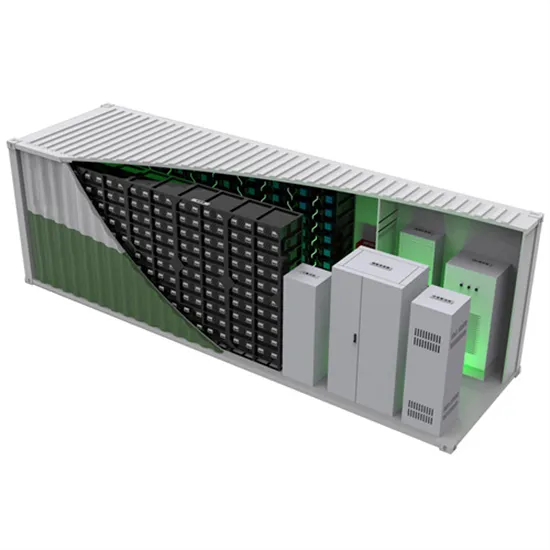

South Africa s solar photovoltaic and storage integrated machine

South Africa s solar photovoltaic and storage integrated machine

-

Solar integrated machine on photovoltaic panel

Solar integrated machine on photovoltaic panel

-

Kazakhstan s solar photovoltaic and storage integrated machine

Kazakhstan s solar photovoltaic and storage integrated machine

-

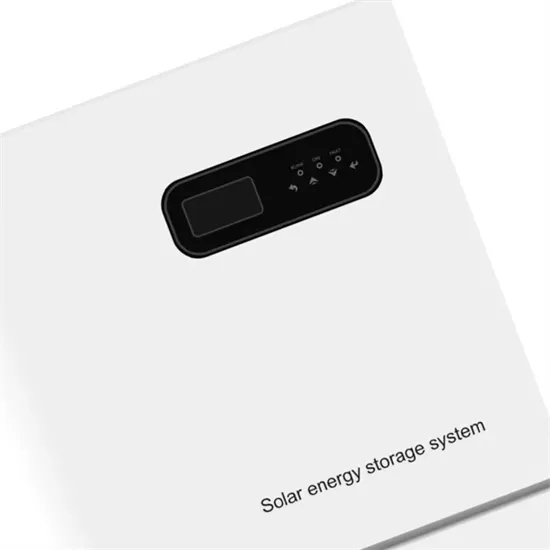

Home photovoltaic power generation solar integrated machine

Home photovoltaic power generation solar integrated machine

-

What is the difference between monocrystalline solar panels and photovoltaic panels

What is the difference between monocrystalline solar panels and photovoltaic panels

-

Home portable solar integrated machine

Home portable solar integrated machine

-

Photovoltaic solar panels in Namibia

Photovoltaic solar panels in Namibia

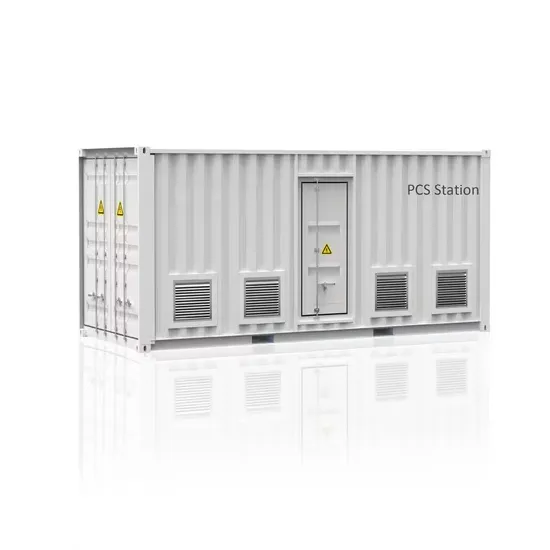

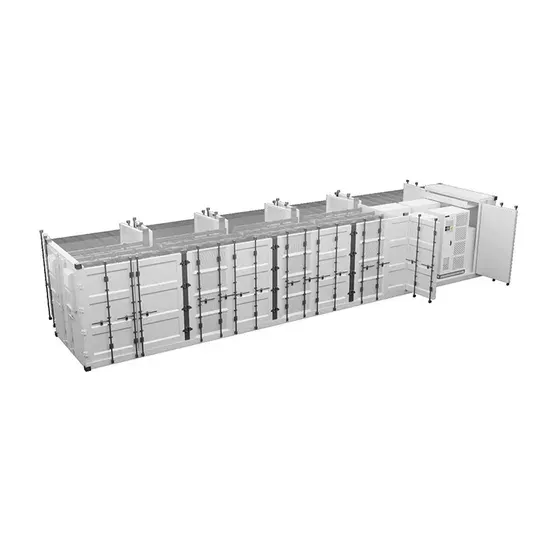

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.