Lithium-ion Battery Cabinets DENIOS

DENIOS'' cutting-edge battery charger cabinets, integrated within our Lithium-Ion Energy Storage Cabinet lineup, guarantee secure and fire-resistant

Get a quote

VoltDrain

The WireFlow VoltDrain system is a robust, modular solution designed specifically to facilitate the safe discharge of electric vehicle (EV) batteries in recycling and discharging facilities.

Get a quote

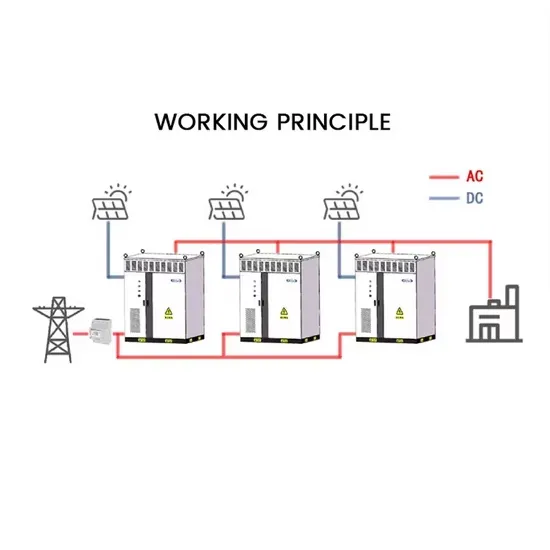

Operation of Energy Storage Battery Cabinets on the Grid Side

Operation of Energy Storage Battery Cabinets on the Grid SideEnergy storage battery cabinets are integral components of energy storage systems. Their operation on the

Get a quote

Choosing the Right Battery Storage Cabinet: A Comprehensive

This comprehensive guide provides a detailed overview of safety, design, compliance, and operational considerations for selecting and using lithium-ion battery storage

Get a quote

Choosing the Right Battery Storage Cabinet: A

This comprehensive guide provides a detailed overview of safety, design, compliance, and operational considerations for selecting and using

Get a quote

Samsung UL9540A Lithium-ion Battery Energy Storage

Overview The Samsung SDI 128S and 136S energy storage systems for data center application are the first lithium-ion battery cabinets to fulfill the rack-level safety standards of the UL9540A

Get a quote

Charge/Discharge Testing of High-Voltage Batteries

An Ideal Data Logger for Recording Cells'' Voltage and Temperature Data Battery charge/discharge testing is carried out as part of performance tests during battery cell,

Get a quote

ELP400 EV Battery Pack Module Charging and Discharging Device

ELP400 has built-in various test and maintenance modes, which are suitable for the discharge, charging, cycle charging and discharging tests of various lithium batteries on the market.

Get a quote

Understanding Battery Discharger Types and Uses

One essential tool for this purpose is the battery discharger. This device helps ensure batteries perform at their best, last longer, and stay safe during use. In this article, we''ll

Get a quote

Battery Cell Dischargers | DV Power

DV Power''s Battery Cell Dischargers are designed to provide secure and efficient deep-discharging of Li-ion cells across industrial settings. These dischargers facilitate the controlled

Get a quote

Battery Cell Dischargers | DV Power

DV Power''s Battery Cell Dischargers are designed to provide secure and efficient deep-discharging of Li-ion cells across industrial settings. These dischargers

Get a quote

DESIGN FOR SAFE AND RELIABLE ELECTRICAL

The selected protection device must trip in case of a fault in less than 100 ms. In case the fault current provided by the battery does not allow for the finding of protection devices, such as a

Get a quote

Understanding Battery Discharger Types and Uses

One essential tool for this purpose is the battery discharger. This device helps ensure batteries perform at their best, last longer, and stay safe

Get a quote

How Safe Is Battery Charging

Battery Chemistry and Charging Risks. Battery safety begins with understanding how different battery types react during charging. Lithium-ion (Li-ion) batteries, found in smartpho

Get a quote

Battery Charge and Discharge Test Chamber|Sanwood Technology

The battery charge&discharge test chamber has a battery charge and discharge cabinet or a charge and discharge device configured in the test chamber. • Can evaluate the battery life of

Get a quote

Battery Pack Module Charging and Discharging

The EP401 is a battery pack module integrated charge-discharge machine designed based on the characteristics of lithium-ion batteries used in electrical

Get a quote

ELP400 EV Battery Pack Module Charging and

ELP400 has built-in various test and maintenance modes, which are suitable for the discharge, charging, cycle charging and discharging tests of various

Get a quote

End-of-Line Vehicle Battery Testing Systems | HORIBA

High-Voltage Battery Testing with X-HVT Charge-Discharge Unit High-Voltage (HV) Battery Testing scheme: Electrical cabinets with PLC Power supply cabinet / control cabinet with PLC;

Get a quote

Battery Charging & Discharging Cabinets

Semco Infratech, a leader in lithium-ion battery assembly offers solutions for battery production, testing, and assembly technology. Maximize efficiency with our Cylindrical Lithium Ion Battery

Get a quote

BTF-70581A, CSEL Battery Discharge Device | Bren

CSEL Battery Discharge Device The BTF-70581A can be used for reconditioning of rechargeable batteries or for a deep discharge prior to

Get a quote

Semco Battery Charge & Discharge Cabinets | Semco Infratech

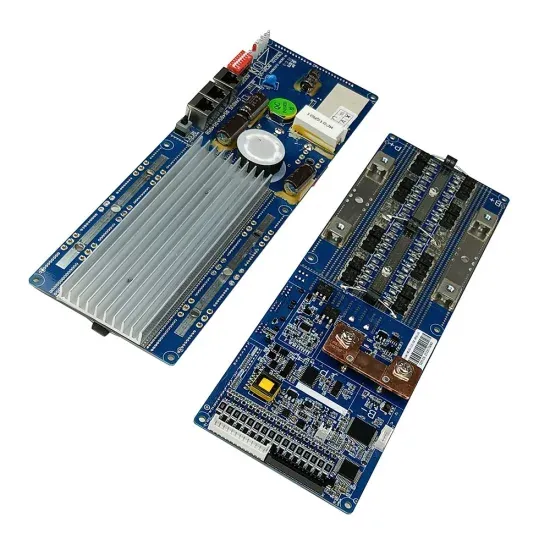

Channels can be detachable, can be customized according to the needs of each channel in the same box in free parallel, to be compatible with a variety of types of battery test, give full play

Get a quote

Amazon : Battery Discharger

EBL 18650 Battery Charger with Discharge & Testing Functions, Lithium Battery Charger for 3.6V/3.7V/3.85V Li-ion/IMR/INR/ICR/3.2VLiFePO4, 1.2V Ni-MH/Ni-CD Rechargeable Batteries

Get a quote

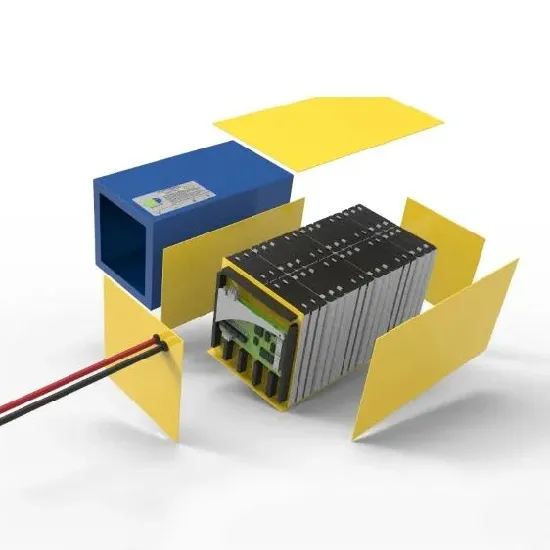

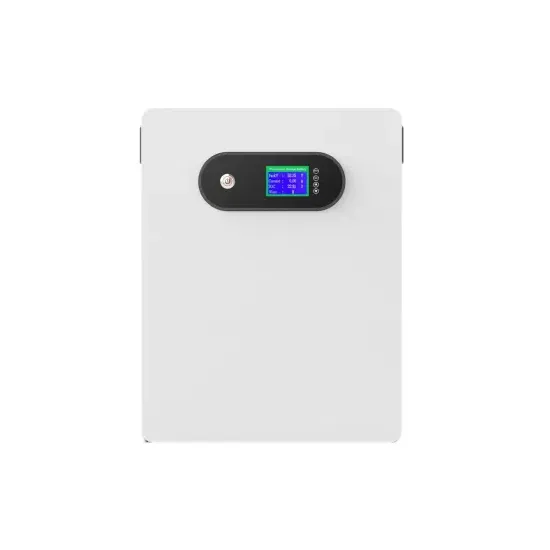

A Guide to Understanding Battery Storage Specifications

Battery Cabinet: A battery cabinet serves as a protective and organized enclosure for housing multiple battery modules within an energy storage system. Its

Get a quote

What is battery capacity cabinet?

Battery capacity cabinets, also known as battery discharge cabinets, are essential devices for testing the capacity of batteries. These cabinets are designed to simulate a load on

Get a quote

Battery Charging & Discharging Cabinets

Semco Infratech, a leader in lithium-ion battery assembly offers solutions for battery production, testing, and assembly technology. Maximize efficiency with

Get a quote

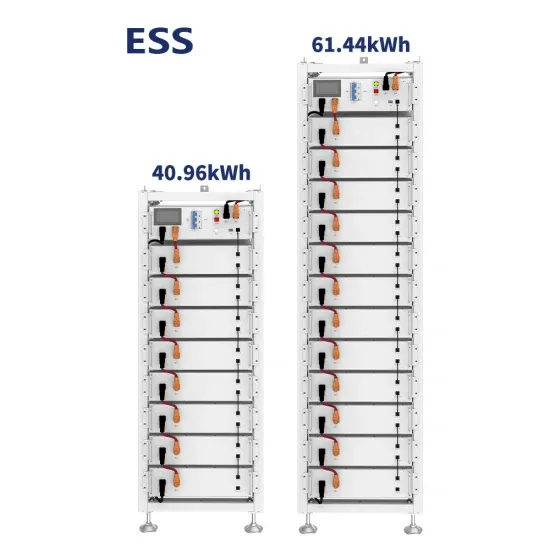

ESS-GRID Cabinet Brochure EN-250401

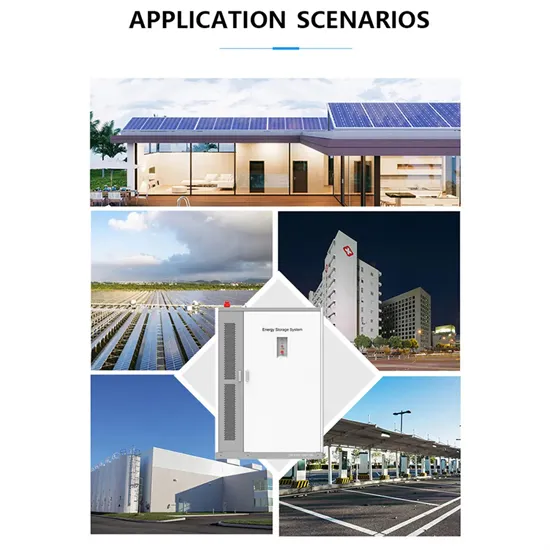

The ESS-GRID Cabinet series are outdoor battery cabinets for small-scale commercial and industrial energy storage, with four diferent capacity options based on diferent cell

Get a quote

Cell charge/discharge test systems | Battery Solution

Structure which integrates a charge/discharge system and temperature chamber to support the future of secondary batteries All-in-one systems combine the

Get a quote

Guide to battery cabinets for lithium-ion batteries

Purpose-built lithium-ion battery storage cabinets are heavy, about 500 kg, so make sure you have a cabinet with an integrated base to evacuate the cabinet with a forklift, both in case of a

Get a quote

6 FAQs about [Battery cabinet discharge device]

What is a battery cell discharger?

Combining safety, adaptability, and ease of use, DV Power’s Battery Cell Dischargers are an ideal choice for industries that demand reliable and rigorous battery management solutions. Battery Cell Dischargers are designed to provide secure and efficient deep-discharging of Li-ion cells across industrial settings.

What is a battery discharger?

A battery discharger is a device that removes stored energy from a battery in a controlled and safe manner. Its primary purpose is to optimize battery health by preventing overcharging, reducing memory effects, and calibrating capacity. Battery dischargers are vital for: Testing a battery’s capacity and performance.

What is a lithium battery discharger?

A lithium battery discharger is specifically designed to handle the sensitive nature of lithium-ion and lithium-polymer cells. Voltage Precision: Ensures the battery discharges to a safe level without over-discharge, which could permanently damage it. High Load Capacity: Can handle the higher capacities and voltages typical of lithium batteries.

Why do you need a battery discharger?

Batteries power a vast array of devices, from everyday electronics to specialized industrial tools. However, maintaining their efficiency and longevity requires proper care and management. One essential tool for this purpose is the battery discharger. This device helps ensure batteries perform at their best, last longer, and stay safe during use.

How does a battery discharger work?

The operation of a battery discharger involves applying an electrical load to the battery, which allows it to release its stored energy in a measured and controlled manner. The process typically includes: Voltage Monitoring: The device tracks the battery’s voltage to ensure it remains within safe discharge limits.

Do You need A AA battery discharger?

AA batteries are ubiquitous, powering everything from remote controls to portable tools. For those using rechargeable AA batteries, such as NiMH or NiCd, a AA battery discharger is indispensable. Multi-Slot Design: Discharge multiple AA batteries simultaneously. Digital Readouts: Display voltage, remaining capacity, and discharge progress.

Guess what you want to know

-

Maximum discharge power of energy storage cabinet battery

Maximum discharge power of energy storage cabinet battery

-

Battery cabinet cooling device base station

Battery cabinet cooling device base station

-

Battery cabinet power generation device

Battery cabinet power generation device

-

How much does the outdoor battery cabinet discharge in watts

How much does the outdoor battery cabinet discharge in watts

-

Battery cabinet with device

Battery cabinet with device

-

There is a sound of electricity in the energy storage battery cabinet

There is a sound of electricity in the energy storage battery cabinet

-

Solar energy storage battery cabinet price

Solar energy storage battery cabinet price

-

How much current does the battery in an ordinary energy storage cabinet have

How much current does the battery in an ordinary energy storage cabinet have

-

Which battery cabinet in Abkhazia has 60v

Which battery cabinet in Abkhazia has 60v

-

360v outdoor battery cabinet

360v outdoor battery cabinet

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.