How To Balance A Lithium Batteries: Top and Bottom Balancing

Many transformers are often required when using the transformer-based active balancing approach, which results in large, costly solutions for battery packs with a high string count.

Get a quote

Active balancing: How it works and what are its advantages

As an alternative to passive balancing, active balancing uses power conversion to redistribute charge among the cells in a battery pack. This enables a higher balancing current,

Get a quote

An Active Balancing Method Based on SOC and

An active balancing method based on the state of charge (SOC) and capacitance is presented in this article to solve the inconsistency problem

Get a quote

How To Balance A Lithium Batteries: Top and Bottom Balancing

A balanced battery pack is critical to getting the most capacity out of your pack, read along to learn how to top and bottom balance a lithium battery pack.

Get a quote

Active Balancing of Lithium-Ion Batteries Using Graph Theory

The heterogeneity of cells in a battery pack is inevitable but brings high risks of premature failure and even safety hazards. Accordingly, for safe and long-life operation, it is necessary to adjust

Get a quote

What is Active Battery Balancing and How Does It Work?

Lithium power battery packs based on active balancing technology can actively balance the differences between lithium power battery cells within the battery pack, whether

Get a quote

Passive Balancing vs Active Balancing in Lithium

Active balancing, also known as active cell balancing, redistributes energy between cells in a lithium battery pack to achieve uniform voltage

Get a quote

An efficient buck-boost converter for fast active balancing of lithium

This article proposes a fast active cell balancing circuit for lithium-ion battery packs. The proposed architecture incorporates a modified non-inverting buck-boost converter to

Get a quote

Battery Balancer Guide: Optimize Performance & Longevity

Battery balancing and battery balancers are crucial in optimizing multi-cell battery packs'' performance, longevity, and safety. This comprehensive guide will delve into the

Get a quote

100BALANCE BMS 60A Active Balance 1A 8S-24S Build in

Enhanced Battery Safety:Daly 100balance active balance BMS offers protection against overcharging, overdischarging, overcurrent,short circuits and extreme temperature,ensuring

Get a quote

Cell Balancing Techniques in Lithium Battery BMS: Passive vs. Active

Explore the key differences between passive and active cell balancing techniques in lithium battery BMS systems. Learn how each method impacts performance, safety, and

Get a quote

A critical review of battery cell balancing techniques, optimal

Considering the significant contribution of cell balancing in battery management system (BMS), this study provides a detailed overview of cell balancing methods and

Get a quote

Overview of Cell Balancing Methods for Li‐ion Battery

This paper presents system modelling and simulation of lithium battery pack with passive cell balancing technique. A battery pack of 57.6 V,

Get a quote

What is Active Battery Balancing and How Does It Work?

Lithium power battery packs based on active balancing technology can actively balance the differences between lithium power battery cells within

Get a quote

Active Balancing: How It Works

Passive balancing reduces cell SOC by placing a resistive load across individual cells (most commonly using BJT or MOSFET transistors). But active balancing takes a switch-mode

Get a quote

Intelligent Cell Balancing Control for Lithium-Ion Battery Packs

This study introduces a balancing control strategy that employs an Artificial Neural Network (ANN) to ensure State of Charge (SOC) balance across lithium-ion (Li-ion) battery packs, consistent

Get a quote

Active cell balancing of lithium‐ion battery pack based

In this study, an active balancing method for charging and discharging of LiB pack based on average state of charge (SOC) is proposed.

Get a quote

Passive Balancing vs Active Balancing in Lithium Batteries

Active balancing, also known as active cell balancing, redistributes energy between cells in a lithium battery pack to achieve uniform voltage levels. Unlike passive methods, which

Get a quote

Optimal Control of Active Cell Balancing for Lithium-Ion Battery Pack

Abstract. Cell balancing control for Li-ion battery pack plays an important role in the battery management system. It contributes to maintaining the maximum usable capacity,

Get a quote

Active Balancing: How It Works

Many transformers are often required when using the transformer-based active balancing approach, which results in large, costly solutions for battery packs with a high string count.

Get a quote

Wiring Balance Leads For Balancer And BMS

We will also discuss the benefits of using an active balancer and we will show you how to wire balance leads for an active balancer and BMS to a

Get a quote

Cell Balancing Techniques in Lithium Battery BMS:

Explore the key differences between passive and active cell balancing techniques in lithium battery BMS systems. Learn how each method

Get a quote

Comparison of Battery balancing methods: Active cell

Lithium-ion (Li-ion) batteries play a crucial role in various applications, including energy storage and electric vehicles. However, they are

Get a quote

An effective passive cell balancing technique for lithium-ion battery

The increasing demand for clean transportation has propelled research and development in electric vehicles (EVs), with a crucial focus on enhancing battery technologies.

Get a quote

Effective Cell Balancing in BMS: Maximizing Battery

Top balancing circuits are simpler and easier to implement than active balancing techniques, keeping the system more cost-effective. Cell

Get a quote

Cell Balancing

Cell balancing is all about the dissipation or movement of energy between cells. The aim being to align them all with respect to state of charge. Aligning the state of charge of all of the cells in a

Get a quote

Guess what you want to know

-

North Asia lithium battery pack supplier

North Asia lithium battery pack supplier

-

Lithium battery pack capacity decreases

Lithium battery pack capacity decreases

-

60v 32ah lithium battery pack

60v 32ah lithium battery pack

-

Assembling the air-cooled lithium battery pack

Assembling the air-cooled lithium battery pack

-

Iraq lithium battery pack customization

Iraq lithium battery pack customization

-

Swiss quality lithium battery pack factory price

Swiss quality lithium battery pack factory price

-

Discharge price of lithium battery pack

Discharge price of lithium battery pack

-

Lithium battery pack resistance difference has a great impact

Lithium battery pack resistance difference has a great impact

-

South America graphene lithium battery pack

South America graphene lithium battery pack

-

Lithuania one lithium battery pack

Lithuania one lithium battery pack

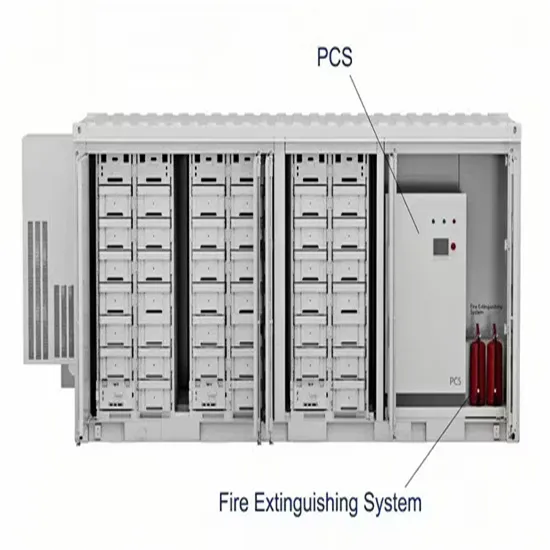

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.