High-efficiency Module,Longi solar module

LONGi launched its mono-PERC modules in 2016, featuring integrated PERC technology on monocrystalline silicon and low light degradation, and its cell

Get a quote

Photovoltaic Cell Generations and Current Research

In particular, the third generation of photovoltaic cells and recent trends in its field, including multi-junction cells and cells with intermediate energy levels in the

Get a quote

Monocrystalline vs Polycrystalline Solar Panels

Creating Silicon Ingots What differs monocrystalline cells from polycrystalline cells is that monocrystalline panels are made of a single pure

Get a quote

Crystalline Silicon Photovoltaics Research

Monocrystalline silicon PV cells can have energy conversion efficiencies higher than 27% in ideal laboratory conditions. However, industrially-produced solar

Get a quote

A Guide to Monocrystalline Solar Panels

The newest monocrystalline solar panels can have an efficiency rating of more than 20%. Additionally, monocrystalline solar cells are the most space-efficient form of silicon solar

Get a quote

Monocrystalline Solar Panels

The article compares monocrystalline and polycrystalline solar panels in terms of their construction, efficiency, suitability for different applications, costs, lifespan, and temperature

Get a quote

Monocrystalline Solar Panels: A Comprehensive Guide

A monocrystalline solar panel is a type of photovoltaic (PV) panel made from a single continuous crystal structure of silicon. This manufacturing process gives the panel a uniform appearance,

Get a quote

Monocrystalline Silicon Cell

Monocrystalline silicon cells are defined as photovoltaic cells produced from single silicon crystals using the Czochralski method, characterized by their high efficiency of 16 to 24%, dark colors,

Get a quote

The difference between monocrystalline silicon and

The magical silicon wafer that converts solar energy into electrical energy is the core of photovoltaic technology. Today, let''s take a closer look at

Get a quote

Crystalline Silicon Photovoltaics Research

The U.S. Department of Energy (DOE) Solar Energy Technologies Office (SETO) supports crystalline silicon photovoltaic (PV) research and development efforts

Get a quote

Mono vs Mono-Perc Solar Panels: The Ultimate Guide

Monocrystalline Solar Panels Mono-crystalline, as the name suggests, are PV panels with cells made up of a single (mono) crystal of Silicone. On the other

Get a quote

Solar panel types and differences: monocrystalline

The main types of solar panels on the market today are monocrystalline silicon, polycrystalline silicon and amorphous silicon solar cells. Differences between

Get a quote

Holistic Assessment of Monocrystalline Silicon (mono-Si) Solar Panels

With the rising demand for lower carbon energy technologies to combat global warming, the market for solar photovoltaics (PVs) has grown significantly. Inevitably, the amount of solar PV

Get a quote

Monocrystalline Solar Panel — Everything You Need To Know

A monocrystalline PV panel is a premium energy-producing panel consisting of smaller monocrystalline solar cells (60 to 72 cells). Their superior aesthetics and efficiency

Get a quote

Photovoltaic Cell Generations | Encyclopedia MDPI

First Generation: This category includes photovoltaic cell technologies based on monocrystalline and polycrystalline silicon and gallium arsenide (GaAs).

Get a quote

Crystalline Silicon Photovoltaics Research

Monocrystalline silicon PV cells can have energy conversion efficiencies higher than 27% in ideal laboratory conditions. However, industrially-produced solar modules currently achieve real

Get a quote

Photovoltaic Cell Generations and Current Research Directions

In particular, the third generation of photovoltaic cells and recent trends in its field, including multi-junction cells and cells with intermediate energy levels in the forbidden band of silicon, are

Get a quote

A small-sized DSSC panel based on the Uruguayan national

Here, we reported the power data generated from a small-sized panel made from cells sensitized with anthocyanins extracted from Uruguay''s National flower: Erythrina crista-galli.

Get a quote

Monocrystalline Solar Panels: Advantages and Disadvantages

Each module is made from a single silicon crystal, and is more efficient, though more expensive, than the newer and cheaper polycrystalline and thin-film PV panel technologies. You can

Get a quote

Monocrystalline silicon: efficiency and manufacturing process

Monocrystalline silicon is the base material for silicon chips used in virtually all electronic equipment today. In the field of solar energy, monocrystalline silicon is also used to

Get a quote

What is Monocrystalline Solar Panel? Advantages and

A monocrystalline solar panel is a solar panel comprising monocrystalline solar cells. The panel derives its name from a cylindrical

Get a quote

Monocrystalline Solar Panels: Advantages and

Each module is made from a single silicon crystal, and is more efficient, though more expensive, than the newer and cheaper polycrystalline and thin-film PV

Get a quote

High-efficiency Module,Longi solar module

LONGi launched its mono-PERC modules in 2016, featuring integrated PERC technology on monocrystalline silicon and low light degradation, and its cell efficiency has increased from

Get a quote

Monocrystalline photovoltaic panels: what they are and their

They are considered an excellent choice for anyone wishing to install a high quality photovoltaic system, whether for residential or industrial use. This article will guide you through

Get a quote

Monocrystalline silicon: efficiency and manufacturing

Monocrystalline silicon is the base material for silicon chips used in virtually all electronic equipment today. In the field of solar energy,

Get a quote

Solar Photovoltaic Manufacturing Basics

Solar manufacturing encompasses the production of products and materials across the solar value chain. This page provides background information on

Get a quote

Experimental comparison between Monocrystalline,

These results are supposed to guide not only solar PV project developers but also policymakers in the selection and implementation of suitable PV technology for a given region.

Get a quote

What kind of silicon is used in solar photovoltaic panels?

1. SILICON TYPES IN SOLAR PHOTOVOLTAIC PANELS Silicon is primarily categorized into three types utilized in solar photovoltaic panels: monocrystalline silicon,

Get a quote

6 FAQs about [Uruguayan monocrystalline silicon photovoltaic panels]

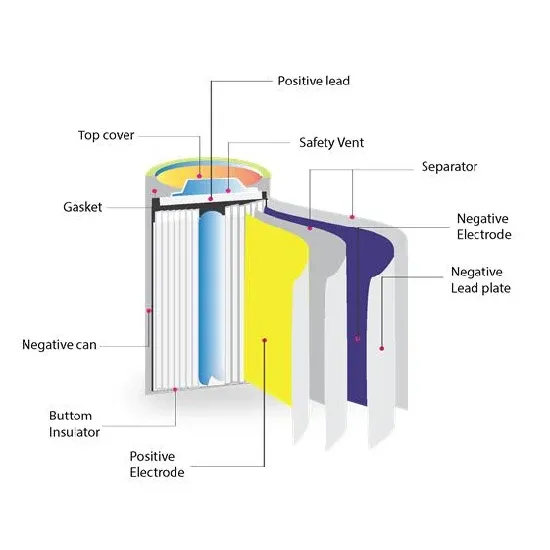

What is a monocrystalline silicon cell?

Monocrystalline silicon cells are defined as photovoltaic cells produced from single silicon crystals using the Czochralski method, characterized by their high efficiency of 16 to 24%, dark colors, and a power output per unit area ranging from 75 to 155 Wp/m². They typically have a more circular shape compared to multi-crystalline cells.

Why is monocrystalline silicon used in photovoltaic cells?

In the field of solar energy, monocrystalline silicon is also used to make photovoltaic cells due to its ability to absorb radiation. Monocrystalline silicon consists of silicon in which the crystal lattice of the entire solid is continuous. This crystalline structure does not break at its edges and is free of any grain boundaries.

How are monocrystalline silicon PV cells made?

Monocrystalline silicon PV cells are produced with the Czochralski method, generated from single silicon crystals. Their manufacturing process is quite expensive since they require a specific processing period. Their energy pay-back time is around 3–4 years (Ghosh, 2020).

What is a monocrystalline silicon solar module?

Monocrystalline silicon represented 96% of global solar shipments in 2022, making it the most common absorber material in today’s solar modules. The remaining 4% consists of other materials, mostly cadmium telluride. Monocrystalline silicon PV cells can have energy conversion efficiencies higher than 27% in ideal laboratory conditions.

Why are solar cells dominated by monocrystalline silicon?

It is noted that the solar cell market is dominated by monocrystalline silicon cells due to their high efficiency. About two decades ago, the efficiency of crystalline silicon photovoltaic cells reached the 25% threshold at the laboratory scale. Despite technological advances since then, peak efficiency has now increased very slightly to 26.6%.

How much power does a monocrystalline silicon cell have?

Monocrystalline silicon cells' power per unit area varies between 75 and 155 Wp/m2 (Petter Jelle et al., 2012). They have a more circular cell shape than multi-crystalline cells (Tripathy et al., 2016).

Guess what you want to know

-

Latest monocrystalline silicon photovoltaic panels

Latest monocrystalline silicon photovoltaic panels

-

The power generation efficiency of monocrystalline silicon photovoltaic panels

The power generation efficiency of monocrystalline silicon photovoltaic panels

-

Better photovoltaic panels than monocrystalline silicon

Better photovoltaic panels than monocrystalline silicon

-

How many types of monocrystalline silicon photovoltaic panels are there

How many types of monocrystalline silicon photovoltaic panels are there

-

Photovoltaic panels are made of monocrystalline silicon

Photovoltaic panels are made of monocrystalline silicon

-

Monocrystalline silicon solar panels 300 watts

Monocrystalline silicon solar panels 300 watts

-

Monocrystalline silicon double-glass bifacial photovoltaic modules

Monocrystalline silicon double-glass bifacial photovoltaic modules

-

Current standards for monocrystalline photovoltaic panels

Current standards for monocrystalline photovoltaic panels

-

Detailed parameters of Kenyan monocrystalline photovoltaic panels

Detailed parameters of Kenyan monocrystalline photovoltaic panels

-

Photovoltaic panels monocrystalline and polycrystalline

Photovoltaic panels monocrystalline and polycrystalline

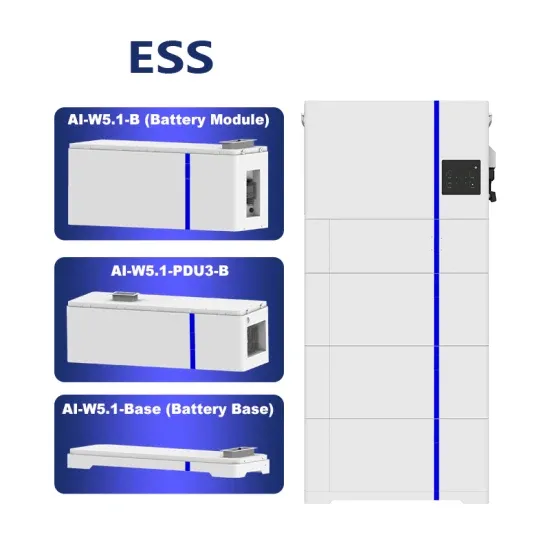

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.