Inspection in Assembly of Li-ion Battery Packs for EVs

Testing times can be reduced by increasing the number of measurement channels, helping shorten lead times. The above instruments can increase the number of channels of the

Get a quote

Advanced Lighting Solutions for EV Battery Inspection

Before the external cover is placed and fastened precisely within a very short cycle time, machine vision inspection systems verify that battery pack

Get a quote

Debunking Lithium-Ion Battery Charging Myths: Best

Explore the truth behind common lithium-ion battery charging myths with our comprehensive guide. Learn the best practices to enhance your battery''s

Get a quote

Inspection in Assembly of Li-ion Battery Packs for EVs

Testing times can be reduced by increasing the number of measurement channels, helping shorten lead times. The above instruments can increase the

Get a quote

What You Need to Know About Lithium Battery Aging Tests

These tests simulate real-world conditions, such as cyclic charge and discharge tests, to assess how batteries degrade over time. By conducting these evaluations, you can

Get a quote

How to calculate the battery pack inspection cycle

Here''''s a useful battery pack calculator for calculating the parameters of battery packs, including lithium-ion batteries. Use it to know the voltage, capacity, energy, and maximum discharge

Get a quote

(PDF) Incoming Inspection of Lithium‐Ion Batteries

Incoming inspections of battery cells prior to module assembly help to ensure the quality of the battery system and prevent the installation of

Get a quote

What You Need to Know About Lithium Battery Aging

These tests simulate real-world conditions, such as cyclic charge and discharge tests, to assess how batteries degrade over time. By

Get a quote

Evaluation and prediction of lithium-ion battery pack

Battery inconsistency problems will inevitably occur in the process of battery operation after forming a pack, and the consistency of the battery pack is of great significance

Get a quote

The Fundamentals of Battery Pack and Module Testing

Key Takeaways Electric vehicle battery testing is critical for evaluating the battery''s condition and overall performance. It involves many

Get a quote

Rechargeable 12V 50Ah 100AhLiFePO4 Battery Lithium Battery Pack

Rechargeable 12V 50Ah 100AhLiFePO4 Battery Lithium Battery Pack Deep Cycle Energy Storage Battery No reviews yet certified Shenzhen Haoyuxin Electronics Co., Ltd. Custom

Get a quote

How often should lithium-ion batteries be inspected | NenPower

Inspecting lithium-ion batteries regularly is crucial for maintaining their health, safety, and performance. Here''s a recommended inspection schedule:

Get a quote

Lithium-ion battery cells incoming inspection solution and equipment

Through the tests of the automatic battery sorter and the battery cycler, the main core test items for the incoming inspection of lithium-ion battery cells have been completed. The remaining

Get a quote

How Many Times Can You Recharge a Lithium-Ion Battery?

A lithium ion battery typically recharges 300 to 500 times. Each full discharge provides a certain energy capacity. Over its lifespan, the total power output ranges from 300 to

Get a quote

Battery Charge-Discharge Test | ESPEC CORP.

Test summary/features The growth of devices running on lithium-ion batteries has created demand for high levels of precision and quality to support various

Get a quote

How often should lithium-ion batteries be inspected

Inspecting lithium-ion batteries regularly is crucial for maintaining their health, safety, and performance. Here''s a recommended inspection

Get a quote

The Fundamentals of Battery/Module Pack Test

Battery module and pack testing is critical for evaluating the battery''s condition and performance. This includes measuring the state of charge (SoC), depth of discharge (DoD), direct current

Get a quote

A Comprehensive Approach to Battery Module and Pack Testing

This research article explores the key elements of battery module and pack testing, providing insights into industry-standard testing procedures and emerging testing methodologies.

Get a quote

Optimized 72V Liquid Battery Pack Design for Smooth Rides on

Our team has over 10-year experience in the lithium rechargeable battery field, we can offer qualified products with reasonable prices and good after-sales service,we hope to cooperate

Get a quote

Lead Acid/Lithium Battery Pack Lifetime Cycle

Lead Acid/Lithium Battery Pack Lifetime Cycle Capacity Performance Lab Tester/Testing Machine, Find Details and Price about Battery Tester

Get a quote

Lithium-Ion Battery Pack Manufacturing Process Guide

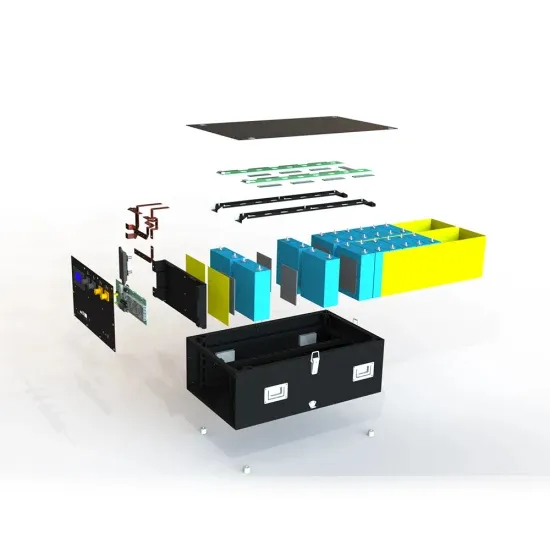

This final stage in the lithium-ion battery manufacturing process integrates individual cells into fully functional battery modules, complete with safety and management systems.

Get a quote

Lithium-ion battery cells incoming inspection solution

Through the tests of the automatic battery sorter and the battery cycler, the main core test items for the incoming inspection of lithium-ion battery cells have

Get a quote

lithium ion

The fact that there is no definitive answer is the limiting factor in the battery development. In a lot of cases, vendors advertise battery life that they are yet to see themselves.

Get a quote

Ultimate Guide: Testing 18650 and 21700 Cells for Battery Packs

A: A complete test cycle, including capacity and cycle testing, can take 2-3 days per cell. However, basic voltage and internal resistance tests can be performed in minutes.

Get a quote

Lithium Battery Pack Assembly: A Comprehensive Guide

Quality control is a cornerstone of the lithium battery pack assembly process. At every stage, inline testing and inspection stations meticulously verify the integrity of the cell

Get a quote

6 FAQs about [Lithium battery pack inspection cycle times]

What are the test items for incoming inspection of lithium-ion battery cells?

Through the tests of the automatic battery sorter and the battery cycler, the main core test items for the incoming inspection of lithium-ion battery cells have been completed. The remaining items are mainly inspected and sampled manually, such as size inspection and appearance inspection.

What is battery module and Pack testing?

Battery module and pack testing involves very little testing of the internal chemical reactions of the individual cells. Module and pack tests typically evaluate the overall battery performance, safety, battery management systems (BMS), cooling systems, and internal heating characteristics.

How is a lithium ion battery inspected?

The remaining items are mainly inspected and sampled manually, such as size inspection and appearance inspection. The size of lithium-ion battery cells is generally measured with a vernier caliper.

How long does it take to test a battery pack?

There is significantly less time available to test during production due to high throughput. Typically the system validation done on the pack level can easily take upwards of 6 minutes per unit. For example, an EV battery manufacturer may plan to manufacture up to 40,000 or more battery packs a year.

Should you test 18650 & 21700 lithium-ion cells before assembling a battery pack?

Testing individual 18650 and 21700 lithium-ion cells before assembling them into a battery pack is crucial for ensuring optimal performance, safety, and longevity of your final product. This comprehensive guide will walk you through the essential steps and techniques for thoroughly evaluating these popular cylindrical cell formats.

What is a battery incoming inspection?

In this process, the actual capacity of the battery cells can also be tested, and the battery cell incoming inspection standards can be compared to determine whether the capacity and cycle life of the battery cells meet the technical and quality requirements.

Guess what you want to know

-

Timor-Leste lithium battery pack cycle life

Timor-Leste lithium battery pack cycle life

-

Cyprus lithium battery battery pack

Cyprus lithium battery battery pack

-

Estimating the capacity of lithium battery pack

Estimating the capacity of lithium battery pack

-

35a lithium battery pack arrangement

35a lithium battery pack arrangement

-

Tuvalu pack lithium battery company

Tuvalu pack lithium battery company

-

Discharge price of lithium battery pack

Discharge price of lithium battery pack

-

What is the volume of a 24v 12A lithium battery pack

What is the volume of a 24v 12A lithium battery pack

-

Tanzania custom lithium battery pack

Tanzania custom lithium battery pack

-

Pack lithium battery assembly price

Pack lithium battery assembly price

-

Introduction to Uzbekistan s solar lithium battery pack

Introduction to Uzbekistan s solar lithium battery pack

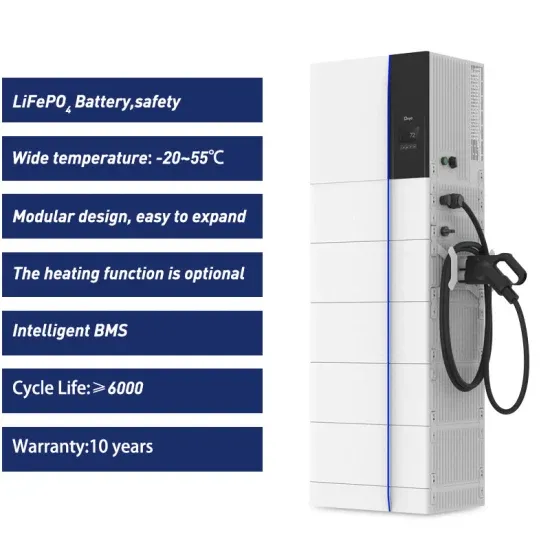

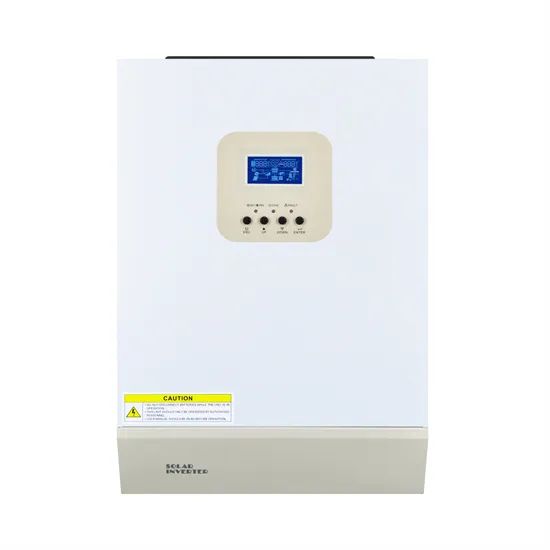

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.