Energy storage container system assembly process

ABB''s containerized energy storage system is a complete,self-contained battery solution for large-scale marine energy storage. The batteries and all control,interface,and auxiliary equipment

Get a quote

2.5MW/5MWh Liquid-cooling Energy Storage System Technical

Project Overview The project features a 2.5MW/5MWh energy storage system with a non-walk-in design which facilitates equipment installation and maintenance, while ensuring long-term safe

Get a quote

Town of Medway Battery Energy Storage System (BESS)

Figure 1: Battery Array Figure 2: Battery Cell Figure 3: Battery Module Figure 4: Battery Container Figure 5: Substation Figure 6: Switchgear Figure 7: Transformer Figure 8: Massachusetts

Get a quote

BESS Decommissioning and End-of-Life Planning:

If you are just starting the permitting process, or in the early stages of BESS project development, this article is for you! A battery energy storage

Get a quote

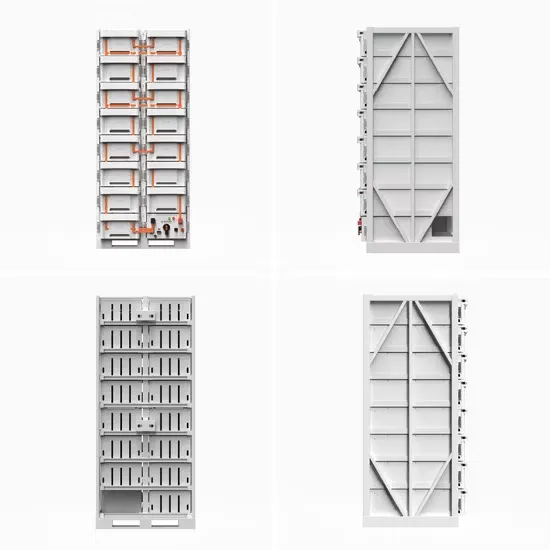

Key Design Principles for Battery Pack Structures in Energy Storage

Explore essential design guidelines for battery pack structures in energy storage systems, focusing on safety, adaptability, thermal protection, and manufacturing efficiency,

Get a quote

Understanding the essentials of battery energy storage system design

Lithium-ion BESS: Engineering the core of energy storage systems In the paper, the authors concentrate on lithium-ion-based systems, leading the charge in the energy

Get a quote

A simple method for the design of thermal energy

One of the key factors that currently limits the commercial deployment of thermal energy storage (TES) systems is their complex design

Get a quote

China Wall Mounted Energy Storage Manufacturers,

Shandong Wina Green Power Technology Co., Ltd: We offer wall mounted home energy storage, stacked energy storage, rack-mounted energy storage and

Get a quote

How are energy storage containers produced? | NenPower

Energy storage containers are produced through a systematic approach that incorporates several stages:1) Design specifications, 2) Material selection, 3) Manufacturing

Get a quote

Energy storage battery system container design

Container energy storage, also commonly referred to as containerized energy storage or container battery storage, is an innovative solution designed to address the increasing

Get a quote

HOW TO DESIGN A BESS (BATTERY ENERGY STORAGE SYSTEM) CONTAINER?

Designing a Battery Energy Storage System (BESS) container in a professional way requires attention to detail, thorough planning, and adherence to industry best practices.

Get a quote

Energy Storage Container Design Flow Chart: A Step-by-Step

Much like how you carefully measure water-to-coffee ratios (unless you''re a chaos-loving espresso shooter), the energy storage container design flow chart requires precision,

Get a quote

Why Your Business Needs a Lithium Battery Storage Container

A Lithium Battery Storage Container securely houses lithium-ion batteries for efficient energy storage, essential for renewable energy integration, backup power, and grid

Get a quote

Designing a BESS Container: A Comprehensive Guide to Battery

Discover the essential steps in designing a containerized Battery Energy Storage System (BESS), from selecting the right battery technology and system architecture to

Get a quote

BATTERY STORAGE FIRE SAFETY ROADMAP

In 2019, EPRI began the Battery Energy Storage Fire Prevention and Mitigation – Phase I research project, convened a group of experts, and conducted a series of energy storage site

Get a quote

DESIGNING A BESS CONTAINER: A COMPREHENSIVE GUIDE TO BATTERY ENERGY

The Battery Energy Storage System (BESS) container design sequence is a series of steps that outline the design and development of a containerized energy storage system.

Get a quote

Park energy storage container layout planning

A bi-level optimal planning method of the electric/thermal hybrid energy storage system for the park-level integrated energy system with the utilization of second-life batteries is

Get a quote

Energy storage containers: an innovative tool in the green energy

The article aims to provide readers with a comprehensive understanding of energy storage container technology to promote its widespread application and promotion in the future

Get a quote

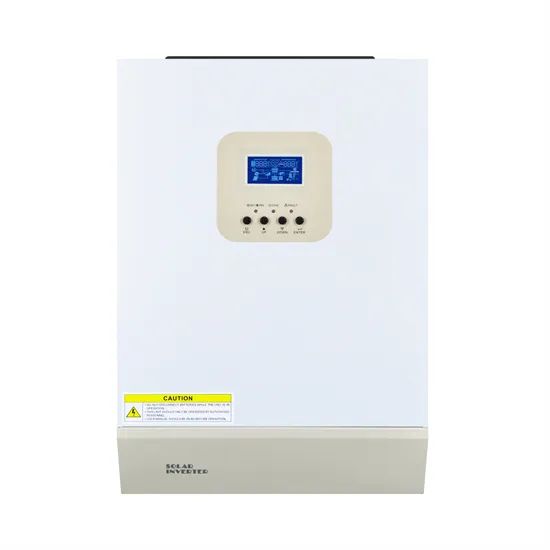

Protecting Solar BESS: Shipping Container Structures for Storage

Its reliability and energy efficiency make the BESS design important for the future of renewable energy. Battery Energy Storage System Design A BESS is a complex device

Get a quote

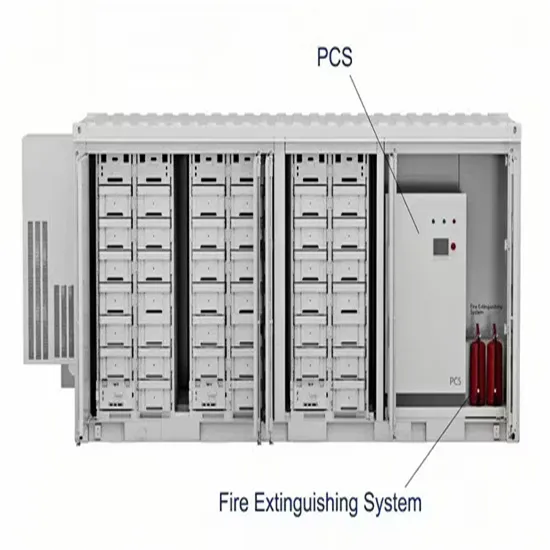

Energy storage container battery module design

The EnerC+ container is a battery energy storage system (BESS) that has four main components: batteries, battery management systems (BMS), fire suppression systems (FSS), and thermal

Get a quote

Key points of energy storage container design

The Battery Energy Storage System (BESS) container design sequence is a series of steps that outline the design and development of a containerized energy storage system.

Get a quote

Shipping Container Energy Storage System Guide

What modifications are essential for a shipping container to be used for energy storage? Can shipping container energy storage systems be

Get a quote

Designing a BESS Container: A Comprehensive Guide to Battery Energy

Discover the essential steps in designing a containerized Battery Energy Storage System (BESS), from selecting the right battery technology and system architecture to

Get a quote

6 FAQs about [Energy Storage Container Design and Development Process]

What is a battery energy storage system (BESS) container design sequence?

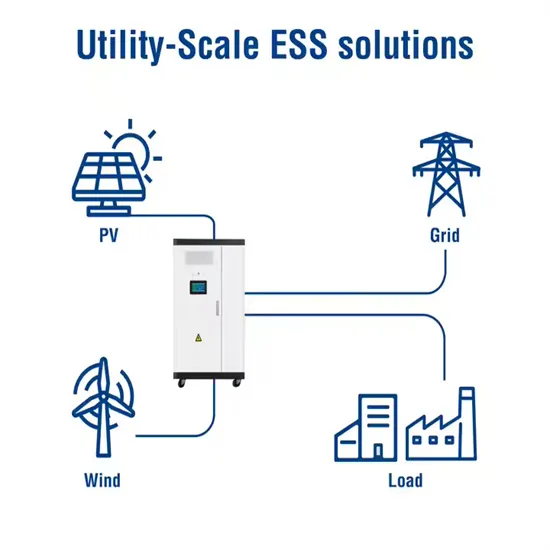

The Battery Energy Storage System (BESS) container design sequence is a series of steps that outline the design and development of a containerized energy storage system. This system is typically used for large-scale energy storage applications like renewable energy integration, grid stabilization, or backup power.

What is an energy storage system?

This system is typically used for large-scale energy storage applications like renewable energy integration, grid stabilization, or backup power. Here's an overview of the design sequence:

How do I design a Bess container?

Here's a step-by-step guide to help you design a BESS container: 1. Define the project requirements: Start by outlining the project's scope, budget, and timeline. Determine the specific energy storage capacity, power rating, and application (e.g., grid support, peak shaving, renewable integration, etc.) of the BESS. 2.

What are the responsibilities of a Bess container?

Transportation and deployment: - Transport the container to the installation site and deploy the BESS system. - Connect the BESS container to the grid or other intended energy sources and loads. 11. Operation and maintenance: - Monitor the performance and health of the BESS container during operation.

What is modularity in a Bess container?

In the context of a BESS container, modularity refers to designing the system using standardized, interchangeable components that can be easily combined, expanded, or replaced as needed. Here are some considerations for implementing modularity in a BESS container design: 1.

What is a standard container size for a Bess enclosure?

1. Standardized container sizes:Utilize standardized ISO container sizes for the BESS enclosure to simplify transportation, logistics, and installation. Common sizes include 20-foot, 40-foot, and 45-foot containers, which are widely available and easily transportable by trucks, trains, or ships.

Guess what you want to know

-

Energy Storage Container Fire Protection System Solution and Process

Energy Storage Container Fire Protection System Solution and Process

-

Walk-in container energy storage assembly process

Walk-in container energy storage assembly process

-

Container configuration energy storage box design

Container configuration energy storage box design

-

Container Energy Storage Process

Container Energy Storage Process

-

Mexican energy storage container design company

Mexican energy storage container design company

-

Global container energy storage design

Global container energy storage design

-

Container Energy Storage Project Design

Container Energy Storage Project Design

-

Container energy storage thermal management design

Container energy storage thermal management design

-

Energy storage container assembly automation design

Energy storage container assembly automation design

-

Japanese container photovoltaic energy storage design

Japanese container photovoltaic energy storage design

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.