How is the inverter manufactured?

In this article, Junchipower will introduce in detail the entire process of inverter production, from design planning to factory delivery, and gradually analyze the key steps and

Get a quote

AN INTRODUCTION TO INVERTER-BASED RESOURCES

Inverter-based resources include modern wind turbines, meaning type 3 and type 4 wind turbines, solar photovoltaic, and battery energy storage resources, as well as high voltage direct current

Get a quote

How do inverters convert DC electricity to AC?

Just as appliances vary in the power they consume, so inverters vary in the power they produce. Typically, to be on the safe side, you''ll need

Get a quote

Solaredge Inverter constantly resetting/not producing

I''ve seen inverter with outdated firmware stop producing power. Since utility update grid profile every 1-3 years, system has to have latest firmware to work

Get a quote

Converting DC to AC: Basic Principles of Inverters

Types of Inverters Inverters can be categorized based on the type of AC power they produce. AC power generated by the grid is of a pure

Get a quote

A review on topology and control strategies of high-power

In reviewing various PWM techniques in LS-PV-PP high-power inverters, we find that these techniques focus on optimizing the conversion of DC power from solar panels to AC

Get a quote

6.4. Inverters: principle of operation and parameters

To produce a sine wave output, high-frequency inverters are used. These inverters use the pulse-width modification method: switching currents at high frequency, and for variable periods of time.

Get a quote

A comprehensive review of multi-level inverters, modulation, and

Conventional two-level inverters have many drawbacks, including higher THD, significant switching losses, and high voltage stress on semiconductor switches within inverter.

Get a quote

Too much of a good thing: Inverter hyper-clipping

Basically, if the inverter isn''t ''clipping'' excess power but the modules are, then does this damage the module? To re-state the process

Get a quote

6.4. Inverters: principle of operation and parameters

The low frequency inverters typically operate at ~60 Hz frequency. To produce a sine wave output, high-frequency inverters are used. These inverters use the

Get a quote

7 Simple Inverter Circuits you can Build at Home

Here''s yet another cool DIY inverter idea which is extremely reliable and uses ordinary parts for accomplishing a high power inverter design, and can be upgraded to any

Get a quote

Harmonics and Noise in Photovoltaic (PV) Inverter and the

1. Introduction PV inverters use semiconductor devices to transform the DC power into controlled AC power by using Pulse Width Modulation (PWM) switching. PWM switching is the most

Get a quote

How to Eliminate Inverter Noise

Have you ever heard a high frequency sound coming from your inverter? How about a knocking or some kind of buzzing noise? There are many possible reasons for those, and this guide shows

Get a quote

800VA Pure Sine Wave Inverter''s Reference Design

The pure Sine Wave inverter has various applications because of its key advantages such as operation with very low harmonic distortion and clean power like utility-supplied electricity,

Get a quote

7 Simple Inverter Circuits you can Build at Home

In this article, Junchipower will introduce in detail the entire process of inverter production, from design planning to factory delivery, and

Get a quote

A High Frequency Variable Load Inverter Architecture

There are many applications that require high-frequency, high-power inverters such as induction heating, plasma generation, and wireless power transfer.

Get a quote

Pure Sine Wave Inverter: All You Need to Know

Pure sine wave inverters are known for their high-quality and reliable power output, making them the preferred choice for a wide range of

Get a quote

A review on topology and control strategies of high-power inverters

In reviewing various PWM techniques in LS-PV-PP high-power inverters, we find that these techniques focus on optimizing the conversion of DC power from solar panels to AC

Get a quote

What is a High-Frequency Power Inverter?

This article provides an overview of high-frequency inverter topologies, design considerations, applications, and advantages versus traditional lower frequency inverters.

Get a quote

How To Produce Inverter: A Step-by-Step Guide

This article will explain how to produce inverter and the key components and walk you through the manufacturing process, from design to final assembly.

Get a quote

What Is An Inverter

The inverter receives DC power from batteries or solar panels and then, converts it into a high-frequency AC power signal. Thereafter, through the use of electronic components

Get a quote

Considerations on the Development of High-Power Density Inverters

This paper aims to compare the maximum output power and losses of inverters with different types (surface-mounted, through-hole-mounted and power modules) of

Get a quote

Does the inverter generate the reactive power from

For example, if the inverter is fed with a 100 kW DC battery and the inverter has to run with 0.9 power factor, it will produce 90 kW of AC power, and the rest 10

Get a quote

How to Fix a Power Inverter? 10 Common Problems & Solutions

The main focus of this article is on how to fix a power inverter. In addition, you will also learn common problems with power inverters and how to avert them.

Get a quote

Guess what you want to know

-

High-power photovoltaic power frequency inverter

High-power photovoltaic power frequency inverter

-

Is a high-power inverter easy to use

Is a high-power inverter easy to use

-

High-power inverter design solution

High-power inverter design solution

-

High-power 48V inverter

High-power 48V inverter

-

High-power home solar water pump inverter

High-power home solar water pump inverter

-

Assembling a high-power inverter

Assembling a high-power inverter

-

Haiti Off-grid Power Frequency 20kw Inverter

Haiti Off-grid Power Frequency 20kw Inverter

-

Inverter 48v to 3v

Inverter 48v to 3v

-

South Ossetia Industrial Inverter Manufacturer

South Ossetia Industrial Inverter Manufacturer

-

Huijue New Energy Inverter Price

Huijue New Energy Inverter Price

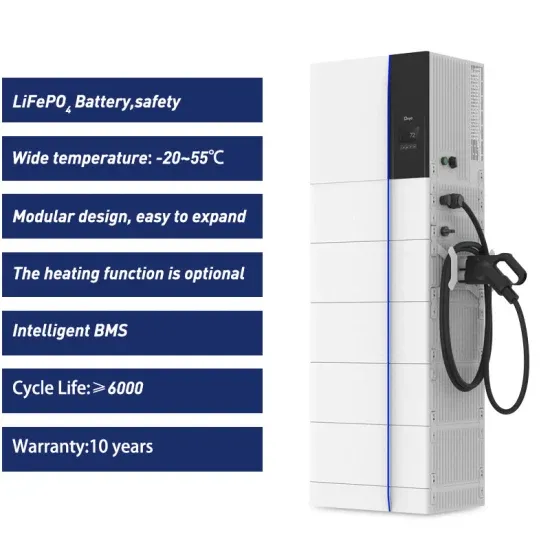

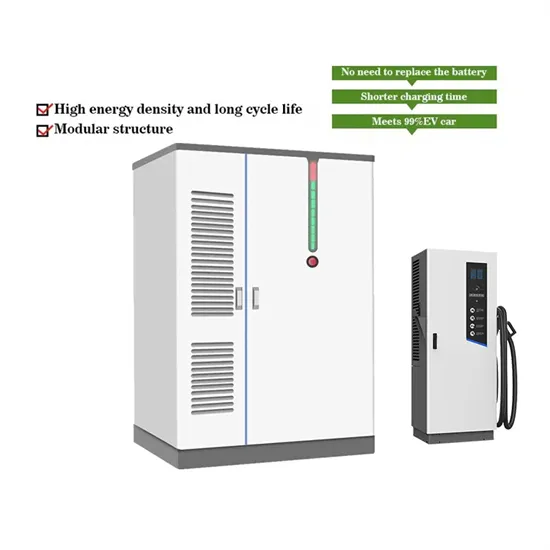

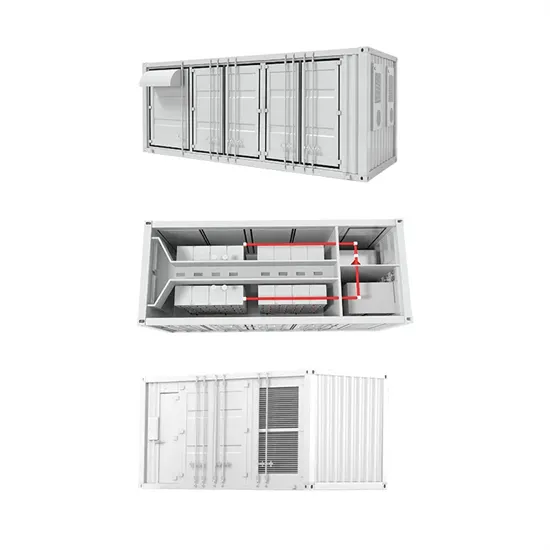

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.