7 Advantages of Bifacial Glass-Backsheet Modules over Glass-Glass Modules

Unlike traditional PV modules, bifacial modules can generate power from both the front and the back, resulting in higher power output within the same space. This has made

Get a quote

The Bifaciality of Solar Panels: A Comprehensive Guide from

Bifacial double-glass solar panels are not suitable for residential rooftop photovoltaic systems and flat commercial and industrial rooftop projects, as these scenarios limit the performance and

Get a quote

The Difference Between Bifacial Module and Double Glass Bifacial Module

In summary, the primary difference between a bifacial module and a double glass bifacial module is the presence of glass on both sides in the latter, which provides improved

Get a quote

Second Wave Of Innovation For Double Glass Modules

There may be an easy-to-see increase in the second half of 2019," says Gessey PV Consulting in China. In March this year, Trina Solar released its next generation of four module

Get a quote

Glass-to-Transparent Backsheet vs. Glass-to-Glass Solar Modules

These modules feature glass on both the front and back, sandwiching the solar cells between two layers of heat-treated, tempered glass. This design enhances the module''s

Get a quote

Bifacial Solar Panels: What are They and Are They Worth It?

The front of a bifacial solar module is covered with a protective glass and the rear side may be made of either glass or transparent polymer backsheet that allows sunlight to

Get a quote

The Difference Between Bifacial Module and Double

In summary, the primary difference between a bifacial module and a double glass bifacial module is the presence of glass on both sides in the

Get a quote

JA Solar 595W JAM72D40 MB N-type Double Glass

The JA Solar JAM72D40 MB modules from the DeepBlue 4.0 series deliver 570–595W with high-efficiency Mono-PERC cells and 16 busbars. Featuring a

Get a quote

The Bifaciality of Solar Panels: A Comprehensive

Bifacial double-glass solar panels are not suitable for residential rooftop photovoltaic systems and flat commercial and industrial rooftop projects, as

Get a quote

Bifacial photovoltaic panels: the new mainstream?

Conventional photovoltaic modules are made with a non-transparent backsheet at their rear side. In constrast, bifacial modules have a

Get a quote

Raytech Double-Glass Modules | Bifacial Solar

Raytech as a manufacturer and supplier of high-quality double glass solar panel, solar module, and solar panel, provide you with high-quality products and

Get a quote

Key Differences Between Half-Cut Modules & Bi

While half-cut modules excel in assuaging cell resistance, augmenting shade tolerance, and bolstering durability, bi-facial modules shine

Get a quote

Dual-glass vs glass-backsheet: The winning formula

Bifacial glass technology is the preferred material among manufacturers for the rear side cover of the modules. Some key advantages

Get a quote

Bifacial Solar Panels: What You Should Know | Renogy US

Bifacial solar panels capture sunlight from both sides. Discover the benefits and drawbacks of this more efficient clean energy solution.

Get a quote

Bifacial Solar Modules | Maysun Solar

The solar cells in bifacial panels are identical to those in monofacial solar panels, with the only difference lying in the panel design. Traditional monofacial panels use an opaque backsheet,

Get a quote

Bifacial photovoltaic panels: the new mainstream?

Conventional photovoltaic modules are made with a non-transparent backsheet at their rear side. In constrast, bifacial modules have a transparent rear side and use bifacial

Get a quote

Glass-to-Transparent Backsheet vs. Glass-to-Glass Solar

These modules feature glass on both the front and back, sandwiching the solar cells between two layers of heat-treated, tempered glass. This design enhances the module''s

Get a quote

JA solar panel n-type bifacial double glass high

Powered by the latest SMBB n-type solar eell and half-cell configuration, these modules have higher output power, lower LID, better weak illumination

Get a quote

PowerPoint Presentation

Benefits Best match for bifacial module, increase system yields 0-touch maintenance, Saving OPEX during entire lifecycle Smart I-V curve 3.0, better match bifacial module and more

Get a quote

Trina 435 TSM-NEG9R.28 Vertex S+ double glass

Multi-busbar technology is integrated, which serves to improve the light-catching effect, reduce series resistance and improve current consumption. This double

Get a quote

JA Solar PV Bifacial Double-glass Modules Installation Manual

This Installation Manual contains essential information for electrical and mechanical installation that you must know before handling and installing JA Solar modules. This Manual also

Get a quote

7 Advantages of Bifacial Glass-Backsheet Modules

Unlike traditional PV modules, bifacial modules can generate power from both the front and the back, resulting in higher power output within

Get a quote

BIFACIAL SERIES – GLASS-TO-GLASS PHOTOVOLTAIC

The bifacial dual sided glass module (G2G) generates more electricity by converting direct, radiant and scattered solar energy on both the front and the back side of the module.

Get a quote

Enhancing optical performance of bifacial PV modules

In this paper, we demonstrate several novel approaches to reduce the transmittance losses and optimize the front side power of the bifacial PV module under standard test

Get a quote

DMEGC 450w N-Type Bifacial Module with Double Glass

The DMEGC DM450M10RT-B54HBT 450W N-Type Bifacial Solar Module is a high-efficiency panel designed for both residential and commercial

Get a quote

Key Differences Between Half-Cut Modules & Bi-Facial Modules

While half-cut modules excel in assuaging cell resistance, augmenting shade tolerance, and bolstering durability, bi-facial modules shine in maximizing energy yield,

Get a quote

Bifacial Solar Panels: What are They and Are They

The front of a bifacial solar module is covered with a protective glass and the rear side may be made of either glass or transparent polymer

Get a quote

455W MBB Bifacial Mono PERC

Introduction Assembled with MBB bifacial PERCIUM cells and half-cell configuration, these double glass modules have the capability of converting the incident light from the rear side together

Get a quote

JA SOLAR PV BIFACIAL DOUBLE-GLASS MODULES

For the bifacial modules, in order to maintain the energy yield of module rear side, the distance between the bottom of modules and the roof or ground surface is recommended be at least 1m.

Get a quote

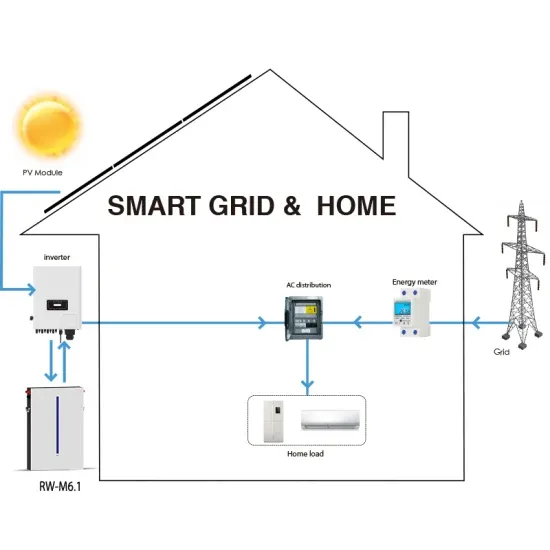

6 FAQs about [Huawei bifacial non-double-glass modules]

What is a bifacial solar module?

The front of a bifacial solar module is covered with a protective glass and the rear side may be made of either glass or transparent polymer backsheet that allows sunlight to pass through. This stands in contrast to conventional solar panels which have opaque backsheets.

Should bifacial panels have double/dual glass?

These days, many bifacial panel designs incorporate double/dual glass at the rear of the modules. Glass-glass panels seems to better transmit light and are more resistant to unpredictable weather, moisture, corrosion, and have good mechanical load capacity.

What are bifacial modules made of?

1. Structural Composition These modules consist of a front glass layer and a rear polymer-based transparent backsheet, typically made from materials like Tedlar or PET (polyethylene terephthalate). The transparent backsheet allows for some light to pass through, which is beneficial for bifacial modules.

What is a bifacial G-B module?

Bifacial G-B modules use a 3.2 mm-thick tempered glass on the front, delivering superior impact strength and durability in comparison to the 2 mm–2.1 mm thick heat-treated glass typically used in G-G modules. The glass used in PV modules generally has a UV transmittance of 40%-50%.

Why are bifacial glass-backsheet modules becoming more popular?

In recent years, an increasing number of module manufacturers have shifted towards transparent backsheets due to their numerous advantages over traditional glass modules. Bifacial Glass-Backsheet (G-B) modules are 17% lighter than Glass-Glass (G-G) modules.

Why do bifacial PV modules have a transparent rear side?

Bifacial PV modules with a transparent rear side collect additional sunlight on the rear side of the module as they capture light reflected from the surface beneath the module and from the surroundings (albedo). As a result, bifacial modules generate additional energy under outdoor conditions [9-11] compared to the standard monofacial modules.

Guess what you want to know

-

Huawei North Asia Solar PV Modules

Huawei North Asia Solar PV Modules

-

Huijue Technology s bifacial photovoltaic modules

Huijue Technology s bifacial photovoltaic modules

-

Huawei now has monocrystalline silicon photovoltaic modules

Huawei now has monocrystalline silicon photovoltaic modules

-

Monocrystalline p-type bifacial double-glass modules

Monocrystalline p-type bifacial double-glass modules

-

High-efficiency bifacial double-glass monocrystalline modules

High-efficiency bifacial double-glass monocrystalline modules

-

Huawei solar panels photovoltaic modules

Huawei solar panels photovoltaic modules

-

Huawei brand all-black double-glass modules

Huawei brand all-black double-glass modules

-

Huawei Croatia Solar Perovskite PV Modules

Huawei Croatia Solar Perovskite PV Modules

-

Huawei supplies energy storage projects

Huawei supplies energy storage projects

-

Huawei Energy Storage Island Construction Project

Huawei Energy Storage Island Construction Project

Industrial & Commercial Energy Storage Market Growth

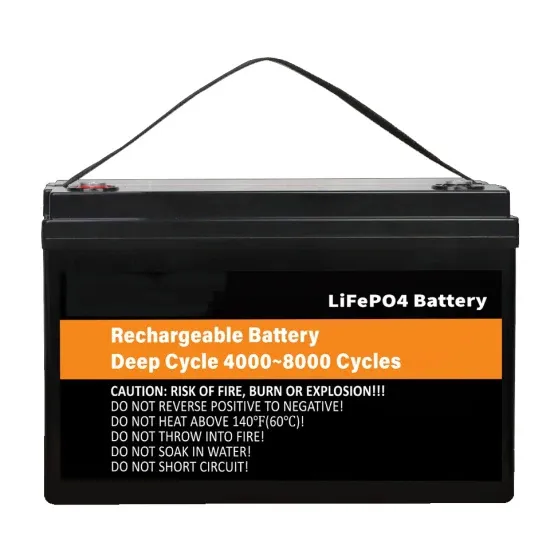

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.