Why are symmetric flow batteries so attractive All vanadium or all iron

From the patent diagram below, it can be seen that all iron flow batteries require a current density of less than 20mA/cm2 at room temperature. Compared to all vanadium flow batteries with a

Get a quote

All-iron redox flow battery in flow-through and flow

These findings highlight the potential of novel non-vanadium chemistries in both flow-through and flow-over cells, prompting further

Get a quote

State-of-art of Flow Batteries: A Brief Overview

In this flow battery system, the cathode is air (Oxygen), the anode is a metal, and the separator is immersed in a liquid electrolyte. In both aqueous and non-aqueous media, zinc, aluminum,

Get a quote

Are iron-flow batteries the solution to variable

The initial investment cost of vanadium batteries is high, but due to the long cycle life of vanadium batteries, they have certain advantages in

Get a quote

Vanadium Redox Flow Batteries: A Safer Alternative to Lithium

Comparing Vanadium Redox Flow Batteries (VRFBs) and Lithium-Ion Batteries, focusing on safety, long-term stability, and scalability for large-scale energy storage solutions.

Get a quote

A comparative study of iron-vanadium and all-vanadium flow battery

This study attempts to answer this question by means of a comprehensively comparative investigation of the iron-vanadium flow battery and the all-vanadium flow battery

Get a quote

All-iron redox flow battery in flow-through and flow-over set-ups:

This study marks the first side-by-side examination of the same all-soluble, all-iron chemistry in flow-through and flow-over cells, revealing substantial configuration-dependent

Get a quote

What are the safety differences between iron flow

In summary, iron flow batteries offer several safety advantages over vanadium flow batteries, including their non-toxic and less reactive

Get a quote

What are the safety differences between iron flow batteries and

In summary, iron flow batteries offer several safety advantages over vanadium flow batteries, including their non-toxic and less reactive nature, lack of thermal runaway risk, and

Get a quote

State of The Art and Future Trends for All-Iron Flow

In particular, two types of AIFBs will be investigated: all-iron hybrid flow batteries (AI-HFB), characterized by the iron plating reaction at the anode, and iron flow batteries with no

Get a quote

Understanding the redox reaction mechanism of vanadium electrolytes

There are hydration structure difference between vanadium ion and water molecules. Vanadium redox flow batteries (VRFBs) have been highlighted for use in energy

Get a quote

How do iron flow batteries compare to vanadium flow batteries in

Higher Efficiency and Energy Density: Vanadium flow batteries offer higher energy density and efficiency compared to iron flow batteries. They can operate effectively over a

Get a quote

WHAT IS THE DIFFERENCE BETWEEN A VFB AND A VANADIUM FLOW BATTERY

While the iron–chromium redox flow battery (ICRFB) is a low-cost flow battery, it has a lower storage capacity and a higher capacity decay rate than the all-vanadium RFB.

Get a quote

State-of-art of Flow Batteries: A Brief Overview

In this flow battery system, the cathode is air (Oxygen), the anode is a metal, and the separator is immersed in a liquid electrolyte. In both aqueous and non

Get a quote

Introduction to types and comparison of iron flow battery

Facing the development needs of the large-scale energy storage field and the high cost of the traditional all-vanadium redox flow battery, the development of

Get a quote

Are iron-flow batteries the solution to variable renewables?

The initial investment cost of vanadium batteries is high, but due to the long cycle life of vanadium batteries, they have certain advantages in terms of full life cycle costs.

Get a quote

Why are symmetric flow batteries so attractive All vanadium or all

From the patent diagram below, it can be seen that all iron flow batteries require a current density of less than 20mA/cm2 at room temperature. Compared to all vanadium flow batteries with a

Get a quote

Analysis of different types of flow batteries in energy

Compared with vanadium, iron has higher utility and lower cost. All-iron flow batteries are divided into acidic and alkaline systems, and acidic

Get a quote

Introduction to types and comparison of iron flow battery

Facing the development needs of the large-scale energy storage field and the high cost of the traditional all-vanadium redox flow battery, the development of the iron flow battery provides a

Get a quote

A comparative study of iron-vanadium and all-vanadium flow

This study attempts to answer this question by means of a comprehensively comparative investigation of the iron-vanadium flow battery and the all-vanadium flow battery

Get a quote

Membrane Considerations for the All-Iron Hybrid Flow

The all-iron flow battery is currently being developed for grid scale energy storage. As with all flow batteries, the membrane in these systems

Get a quote

Go with the flow: What are flow batteries, and how do they work?

The Queensland Government''s recently announced Queensland Energy and Jobs Plan commits $500 million to grid-scale and community batteries, including flow batteries,

Get a quote

Mathematical modeling and in-depth analysis of 10 kW-class iron

The iron-vanadium flow batteries (IVFBs) employing V2+ /V 3+ and Fe 2+ /Fe 3+ as active couples are regarded as promising large-scale energy storage technologies,

Get a quote

Flow batteries for grid-scale energy storage

A modeling framework by MIT researchers can help speed the development of flow batteries for large-scale, long-duration electricity storage

Get a quote

All-Soluble All-Iron Aqueous Redox-Flow Battery

The rapid growth of intermittent renewable energy (e.g., wind and solar) demands low-cost and large-scale energy storage systems for smooth

Get a quote

Are iron-flow batteries the solution to variable

Comparison vanadium battery vs lithium, All-vanadium redox flow battery is a water circulation system, which is non-flammable and does not

Get a quote

Principle, Advantages and Challenges of Vanadium Redox Flow Batteries

Reproduction of the 2019 General Commissioner for Schematic diagram of a vanadium flow-through batteries storing the energy produced by photovoltaic panels.

Get a quote

Introduction guide of flow battery

At present, China''s largest flow battery demonstration project has achieved 100 MW/400 MWh. At present, there are three technical routes for flow batteries to

Get a quote

Analysis of different types of flow batteries in energy storage field

Compared with vanadium, iron has higher utility and lower cost. All-iron flow batteries are divided into acidic and alkaline systems, and acidic all-iron flow batteries are

Get a quote

6 FAQs about [Differences between all-iron and all-vanadium flow batteries]

Is all-iron flow battery performance dependent on cell configuration?

All-soluble, all-iron flow battery performance is critically dependent upon cell configuration. Flow-through and flow-over designs exhibit stark differences in efficiency, maximum power density, capacity retention, and self-discharge.

How are the performance of two flow batteries analyzed?

The overall performances of the two flow batteries are examined by experimental methods. The capital costs are analyzed on the basis of a real 250 kW flow battery module. There are four following parts in the rest of this paper. The experimental methods and conditions are shown in section 2.

What causes the capacity decay of iron-vanadium flow batteries?

Thus, the capacity decay of Iron-vanadium flow batteries can be mainly attributed to the ion diffusions across the membrane. In the main, the capacity retention ability of VFB is superior to that of IVFB, because the VFB capacity is not only higher after 500 cycles, but also without unexpected fluctuation during the whole testing.

What are Li-ion batteries & redox flow batteries?

Li-Ion Batteries (LIBs) and Redox Flow Batteries (RFBs) are popular battery system in electrical energy storage technology. Currently, LIBs have dominated the energy storage market being power sources for portable electronic devices, electric vehicles and even for small capacity grid systems (8.8 GWh) .

What are the advantages and disadvantages of organic redox flow batteries?

The redox reaction and voltage generated with respect to SHE is given below: Advantages: · Low-cost flow battery system. Disadvantages: · Low energy density · Slow exchange of Chromium ions · Evolution of hydrogen at the anode · High chance of crossover. Aqueous OrganicRedox Flow Batteries (AORFBs)

Why does VfB cost so much compared to ion exchange membranes?

For VFB, 62.79% of the total cost comes from the electrolyte owing to the high cost of vanadium resources. By comparison, the second largest part of the ion exchange membrane accounts for only 10% benefited from the cost down of the providers.

Guess what you want to know

-

Which type of vanadium is used in all-vanadium liquid flow batteries

Which type of vanadium is used in all-vanadium liquid flow batteries

-

Cost per kilowatt-hour of all-vanadium redox flow batteries

Cost per kilowatt-hour of all-vanadium redox flow batteries

-

Alkaline all-vanadium flow battery price

Alkaline all-vanadium flow battery price

-

How to build liquid flow batteries for small communication base stations in Bangladesh

How to build liquid flow batteries for small communication base stations in Bangladesh

-

Do vanadium liquid flow batteries require phosphoric acid

Do vanadium liquid flow batteries require phosphoric acid

-

Global ranking of flow batteries for communication base stations

Global ranking of flow batteries for communication base stations

-

Sierra Leone all-vanadium flow battery

Sierra Leone all-vanadium flow battery

-

10kw all-vanadium redox flow battery

10kw all-vanadium redox flow battery

-

Albania Liquid Flow All-Vanadium Energy Storage Power Station

Albania Liquid Flow All-Vanadium Energy Storage Power Station

-

Zinc-based flow batteries and vanadium batteries

Zinc-based flow batteries and vanadium batteries

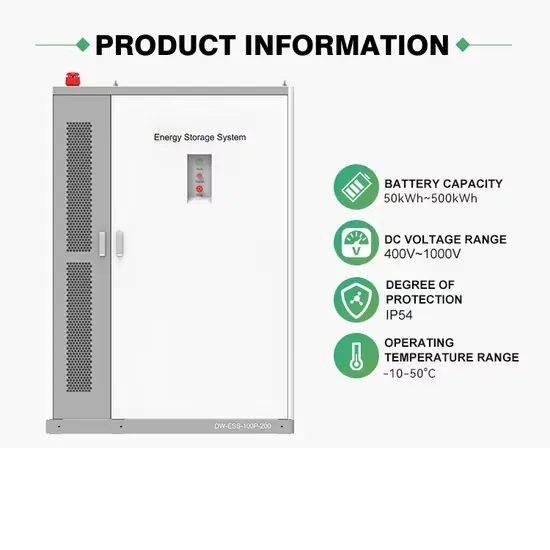

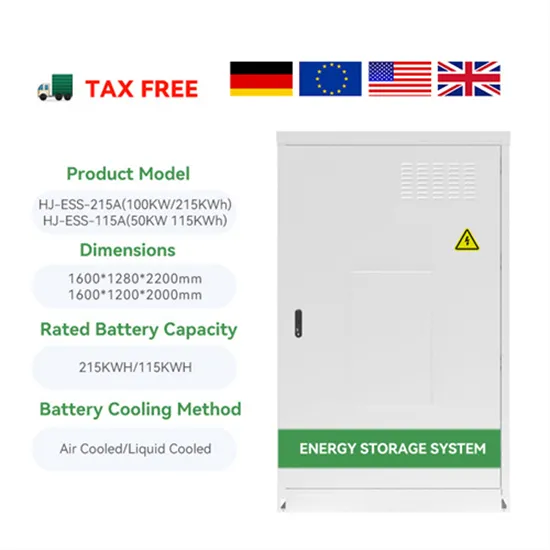

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.