How does a liquid-cooled energy storage cabinet dissipate heat

The working principle of the liquid cooling system in the energy storage cabinet is mainly divided into the following steps: Coolant circulation: The core of the liquid cooling system is the

Get a quote

Study on uniform distribution of liquid cooling pipeline in container

Designing a liquid cooling system for a container battery energy storage system (BESS) is vital for maximizing capacity, prolonging the system''s lifespan, and improving its

Get a quote

How does the liquid cooling system work in the energy storage cabinet

Heat exchange: The circulating coolant flows through the battery modules in the energy storage cabinet through a heat exchanger (usually a series of carefully designed pipes or plate heat

Get a quote

Engineering Design of Liquid Cooling Systems in

Key design components such as heat exchangers, pumps, and thermal interface materials play a decisive role in determining how efficiently

Get a quote

Liquid-cooled energy storage cabinet components

Liquid-cooled energy storage cabinets significantly reduce the size of equipment through compact design and high-efficiency liquid cooling systems, while increasing power density and energy

Get a quote

How Energy Storage Liquid Cooling Works: A Cool Solution for a

thousands of batteries working overtime in a storage facility, generating enough heat to fry an egg. Enter energy storage liquid cooling – the unsung hero keeping these powerhouses from

Get a quote

Working principle of energy storage cabinet liquid cooling

By employing high-volume coolant flow, liquid cooling can dissipate heat quickly among battery modules to eliminate thermal runaway risk quickly - and significantly reducing loss of control

Get a quote

Liquid Cooling Battery Cabinet: Maximize Efficiency Now

The ability to manage heat effectively allows these systems to offer high-capacity, dependable power for businesses aiming to optimize their energy management and embrace

Get a quote

Liquid-Cooling ESS: The Key to Efficient Energy Storage

Discover the benefits of liquid-cooling ESS for efficient energy storage systems. Improve battery lifespan, enhance safety, and optimize performance with advanced liquid

Get a quote

Cabinet Cooling: A Key Aspect in Energy Storage Systems

Firstly, excessive heat can cause a significant reduction in the efficiency of the energy storage system. High temperatures can increase the internal resistance of batteries,

Get a quote

Energy Storage System Cooling

Thermoelectric coolers serve a cooling capacity spectrum from approximately 10 to 400 Watts, and can cool by removing heat from control sources through convection, conduction, or liquid

Get a quote

LIQUID-COOLED POWERTITAN 2.0 BATTERY ENERGY

A patented liquid-cooled heat dissipation scheme and 4D sensing technology maintain a balanced system temperature with a ≤ 2.5°C temperature difference across all

Get a quote

Engineering Design of Liquid Cooling Systems in Energy Cabinets

Key design components such as heat exchangers, pumps, and thermal interface materials play a decisive role in determining how efficiently heat is removed and dissipated.

Get a quote

How does the liquid cooling system work in the energy

Heat exchange: The circulating coolant flows through the battery modules in the energy storage cabinet through a heat exchanger (usually a series of carefully

Get a quote

The difference between air cooling and liquid cooling

Liquid cooling dissipates heat by using a liquid medium (such as water and a water-glycol solution) for thermal exchange, resulting in high cooling efficiency

Get a quote

The Ultimate Guide to Liquid-Cooled Energy Storage Cabinets

Liquid cooling is a method that uses liquids like water or special coolants to dissipate heat from electronic components. Unlike air cooling, which relies on fans to move air

Get a quote

Liquid Cooling: Efficiency in Battery Storage

The Evolution of Energy Storage Cooling As the world transitions towards renewable energy sources, the demand for efficient and reliable Commercial & Industrial (C&I)

Get a quote

Comparison of cooling methods for lithium ion battery

Comparison of cooling methods for lithium ion battery pack heat dissipation: air cooling vs. liquid cooling vs. phase change material cooling vs.

Get a quote

Liquid Cooling Battery Cabinet: Future of Energy Storage

Liquid Cooling Technology offers a far more effective and precise method of thermal management. By circulating a specialized coolant through channels integrated within or

Get a quote

THERMAL MANAGEMENT FOR ENERGY STORAGE: UNDERSTANDING AIR AND LIQUID

Liquid cooling systems use a liquid as a cooling medium, which carries away the heat generated by the battery through convective heat exchange. The structural form of a

Get a quote

Frontiers | Research and design for a storage liquid

Based on the device status and research into industrial and commercial energy storage integrated cabinets, this article further studies the

Get a quote

How Can Liquid Cooling Revolutionize Battery Energy

With the rapid advancement of technology and an increasing focus on energy efficiency, liquid cooling systems are becoming a game-changer across

Get a quote

How does the energy storage liquid cooler dissipate heat?

Unlike air cooling, which relies solely on convection, liquid coolers employ a fluid medium that facilitates superior heat transfer due to its increased density and specific heat

Get a quote

Liquid Cooling Battery Cabinet Efficiency & Design

Unlike air cooling, which relies on circulating air to dissipate heat, liquid cooling uses a specialized coolant that flows through pipes or plates integrated within the battery cabinet.

Get a quote

Guess what you want to know

-

How much does a liquid-cooled energy storage battery cabinet cost in China

How much does a liquid-cooled energy storage battery cabinet cost in China

-

How does a liquid-cooled energy storage cabinet store energy

How does a liquid-cooled energy storage cabinet store energy

-

How does the solar energy storage cabinet work

How does the solar energy storage cabinet work

-

Liquid-cooled energy storage lithium battery station cabinet base station power system

Liquid-cooled energy storage lithium battery station cabinet base station power system

-

Air-cooled energy storage battery compartment and liquid-cooled energy storage battery cabinet

Air-cooled energy storage battery compartment and liquid-cooled energy storage battery cabinet

-

Domestic liquid-cooled outdoor battery cabinet Huijue Energy Storage

Domestic liquid-cooled outdoor battery cabinet Huijue Energy Storage

-

Liquid-cooled integrated energy storage cabinet

Liquid-cooled integrated energy storage cabinet

-

New energy liquid-cooled energy storage battery Cabinet additions

New energy liquid-cooled energy storage battery Cabinet additions

-

String liquid-cooled energy storage battery cabinet

String liquid-cooled energy storage battery cabinet

-

How to Become an Energy Storage Cabinet Battery Agent

How to Become an Energy Storage Cabinet Battery Agent

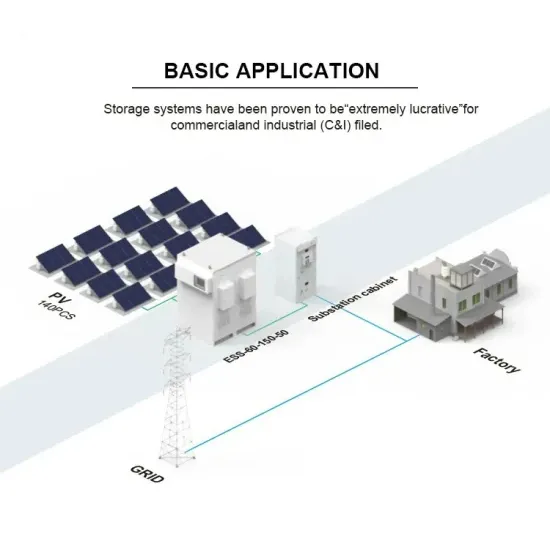

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.