Underground Mine Communication Infrastructure Guidelines

The backbone/core communications system could be hybrid leaky feeder supporting digital communica-tions, Wi-Fi®, fibre optic cabling, or a combination of technologies to provide the

Get a quote

Communications in Underground Mine | SpringerLink

Communications in underground mines include bus communication, wired telephone communication, industrial Ethernet communication, and wireless communication.

Get a quote

Mine Rescue System, Wireless Communication Systems | Mining

The Mine Rescue Operations Wireless Communication System ensures communication in the mining excavation during activities related to the rescue operation. The

Get a quote

UPS Batteries in Telecom Base Stations – leagend

This article delves deep into the role, technology, maintenance, and future trends of UPS batteries in telecom base stations, offering a detailed

Get a quote

Surface Mine Communication

Base antennas: When it comes to VHF and UHF antennas, RFI consistently outperforms the competition every time. Mobile antennas for vehicles: many of the public safety networks turn

Get a quote

How Mine Communication Networks Improve Production

Production data can now be collected from multiple sources including machinery, automated systems, conveyors, proximity sensors, dust detectors, etc. This data can be aggregated and

Get a quote

ITP Mining: Through the earth communications for the mining

The low cost of the radios allow for large number of such stations to relay the data throughout the mine. The use of electronics specialized to very low frequencies in communication equipment

Get a quote

4 types of Base stations

Macro cell, Micro cell, Pico cell and Femto cell are 4 types of base stations in wireless communication networks. Macro Base Station Macrocell antennas must be properly mounted

Get a quote

Mining Communication Base Station

Communication base station setups will usually include a wide array of different technologies, including power supplies, data servers, head end, radio

Get a quote

Becker Wholesale Mine Supply

Fixed Base Stations: Installed at strategic points within the mine, base stations facilitate communication by acting as relay points between handheld radios and the surface.

Get a quote

Base Stations and Cell Towers: The Pillars of Mobile

Base stations and cell towers are critical components of cellular communication systems, serving as the infrastructure that supports seamless

Get a quote

(PDF) Surface Electromagnetic Wave-Based Wireless Communication

The results obtained prove the fundamental possibility of designing multichannel induction communication systems with a guaranteed communication range of over 4 km from

Get a quote

Underground Mine Communications Infrastructure

Many new technologies developed and sold by vendors require high-speed digital networks to manage the increas-ing volumes of data generated in the underground mining environment.

Get a quote

Uses for Mining Communications Systems

Many radios used in a modern mining network come equipped with GPS applications and indoor location tracking capabilities. This allows site managers to know where every team member is

Get a quote

Mining Communication Base Station

Communication base station setups will usually include a wide array of different technologies, including power supplies, data servers, head end, radio repeaters, and communication

Get a quote

CN115968061A

The invention discloses a mobile communication base station used in a coal mine, which comprises a shell, a communication base station, a shielding rotating frame and a screw; the

Get a quote

Base Station''s Role in Wireless Communication Networks

A base station is the component of the network that handles communication between devices and the network, while a cell tower is the physical structure that houses the antennas and

Get a quote

KT661 (5G)-F Explosion-proof and Intrinsically Safe Communication Base

The base station is a kind of coal mine communication equipment for 5G wireless communication in coal mines. It is used with 5G terminals and 5G smart gateways, supporting mobile voice

Get a quote

6 FAQs about [What equipment does the mine communication base station have ]

What is a mining communication base station?

Our mining communication base stations are innovatively built to fit your specific project’s needs. Our semi-portable LTE base stations are modular, standalone, fully self-supporting units forging the way in long range communications solutions for remote mining operations. Mining relies on communication technology.

What is a communication base station?

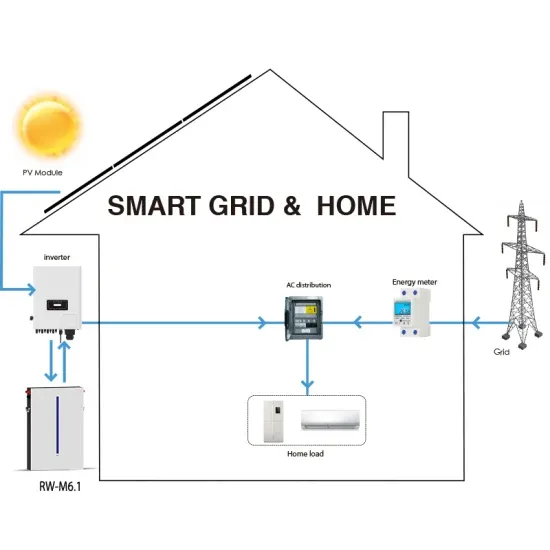

Communication base station setups will usually include a wide array of different technologies, including power supplies, data servers, head end, radio repeaters, and communication systems that allow for high-speed continuous information flow. It can also be used as part of a leaky feeder system in the communication network.

What is a base station in a mine?

Fixed Base Stations: Installed at strategic points within the mine, base stations facilitate communication by acting as relay points between handheld radios and the surface. These stations ensure coverage over a large area, allowing workers to remain in contact even when they are far from each other.

What type of communication system do mines use?

For stationary units or worksites, cable-based (wired) communication sys-tems are normally adequate; wireless systems should be used for mobile units. There is a tendency for underground mines to use a sin-gle communication network for both voice and data.

Can a mining base station be used as a communications tower?

Our mining communication base stations can also host mast systems up to 32 metres high, depending on your selected model, meaning it can easily be used as an off-grid communications tower. Or use our base station next to a fixed tower for power and communications without the need for site services.

What audio communication systems are suitable for underground mines?

There are several audio communications systems that are suitable for underground mines (Table 6). The systems range from very simple to very complex. One simple option is a mine phone system. A battery-operated phone is placed at a control location at the surface or entrance into the mine.

Guess what you want to know

-

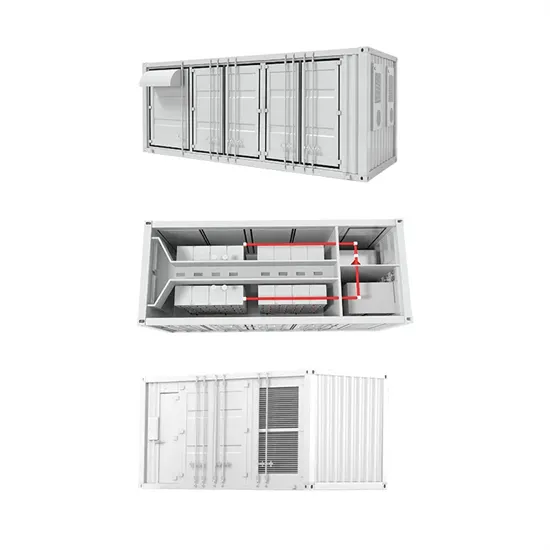

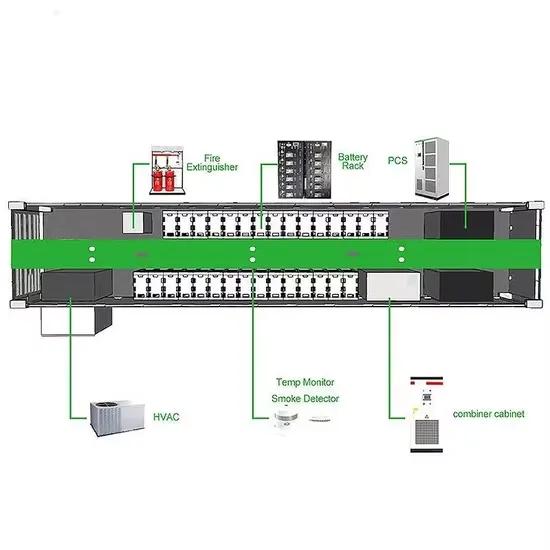

What are the manufacturers of emergency communication base station energy storage system equipment

What are the manufacturers of emergency communication base station energy storage system equipment

-

What is the square shape of base station communication equipment

What is the square shape of base station communication equipment

-

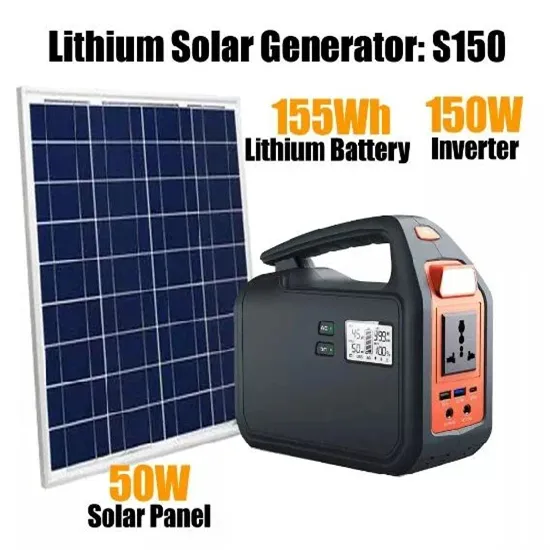

What are the photovoltaic power generation of base station communication equipment

What are the photovoltaic power generation of base station communication equipment

-

What does civil base station communication equipment include

What does civil base station communication equipment include

-

What types of equipment are connected to the grid for communication base station inverters

What types of equipment are connected to the grid for communication base station inverters

-

What are the mobile base station communication equipment

What are the mobile base station communication equipment

-

What is the minimum voltage of a communication base station

What is the minimum voltage of a communication base station

-

Appearance characteristics of base station communication equipment

Appearance characteristics of base station communication equipment

-

South African communication base station energy storage equipment manufacturer

South African communication base station energy storage equipment manufacturer

-

Base station communication equipment wind power

Base station communication equipment wind power

Industrial & Commercial Energy Storage Market Growth

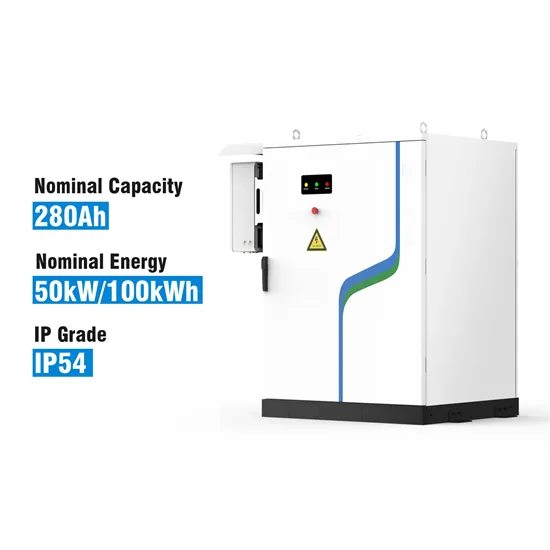

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.