What are busbars, what are their types, and why are

These busbars are appropriately insulated or enhanced for conductivity with galvanic coatings (silver-plating, nickel-plating, copper

Get a quote

What is a Busbar? The Key to DIY Solar Power

In solar panels, busbars are the thin rectangular strips that separate solar cells and conduct electricity. It takes the electrons, once separated from

Get a quote

What Is A Busbar And Do I Actually Need One?

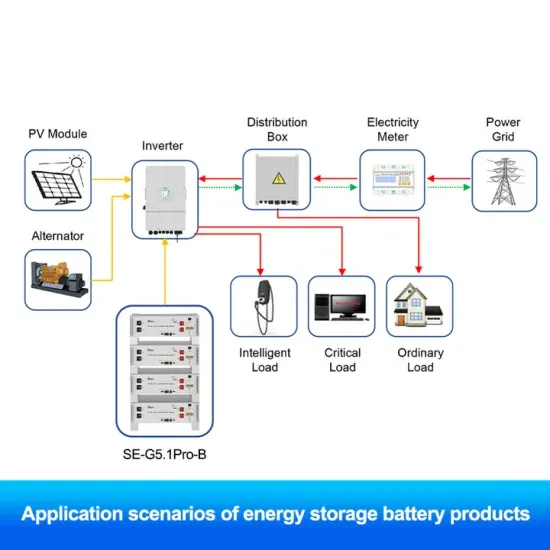

Inverter connections: Busbars can be used to connect the output of your inverter to the distribution panel or to connect multiple inverters together if you have a multi-inverter setup.

Get a quote

MBB Technology – Multi-Busbar and Silver Use in

Solar cells have a narrow, rectangular Busbar on both sides. The complete solar cell strip transmits electricity. This strip separates cells so photons can pass

Get a quote

Busbar for solar power systems: The key to optimal

In the solar power system, the Busbar is made of silver-plated copper, responsible for collecting current from the photovoltaic cells on the

Get a quote

Busbar for solar power systems: The key to optimal performance

In the solar power system, the Busbar is made of silver-plated copper, responsible for collecting current from the photovoltaic cells on the battery panel and transmitting it to the

Get a quote

Solar busbars. How are busbars used in photovoltaic

Standard silicon PV cells have specially prepared soldering points for this strip on their back and front side. These contact strips at the front and

Get a quote

Combined Ground and Neutral — northernarizona-windandsun

Hey Installers, I have a question that maybe be remedial. I often see ground and neutral on the same (and only) bus bar in a main panel.

Get a quote

FEEDER TAP 705.12 (B) (2) (1b) NEC 2017

1) Yes, 705.12 (B) applies to every feeder or panel between the PV inverter and the utility. A feeder with an interconnection is subject to 705.12 (B) (2) (1); if the feeder just has

Get a quote

Placement of backfeed breaker

Ask your questions about solar modules, mounts, inverters or any other part of your solar energy system. If you want to share the specs for your system, then you can post

Get a quote

Improving Panel Efficiency: Solar Cell Busbars and Fingers

One of the main components of any solar energy system is the sleeve beam, which connects the solar panels to the inverter. A photovoltaic beam is a type of busbar specially

Get a quote

The Critical Role of Busbars in Renewable Energy

l Inverters: Inverters convert the collected DC into AC, which can then be fed into the grid or used on-site. Busbars help manage the input and output currents

Get a quote

Solar busbars. How are busbars used in photovoltaic panels?

Standard silicon PV cells have specially prepared soldering points for this strip on their back and front side. These contact strips at the front and back are also called ''bus bars''

Get a quote

Do I need a bus bar? Why not connect inverter

Know it''s not your block diagram, but as I look up a 2128 Buss bar, this is seems to be designed for six screw connections for #20 - #10 ring terminals, so is I''m reading it right, a

Get a quote

What is a Busbar? The Key to DIY Solar Power

Explore the role of busbars in solar power systems with our in-depth guide. Learn what a busbar is, how to install one in a 12V DIY solar setup, and more.

Get a quote

Which is the solar busbar? | NenPower

A solar busbar acts as a conductive medium in photovoltaic systems that connects multiple solar cells, enabling the efficient transmission of electricity. The main purpose is to

Get a quote

Improving Panel Efficiency: Solar Cell Busbars and

One of the main components of any solar energy system is the sleeve beam, which connects the solar panels to the inverter. A photovoltaic

Get a quote

What Is A Busbar And Do I Actually Need One?

Inverter connections: Busbars can be used to connect the output of your inverter to the distribution panel or to connect multiple inverters together if you have a

Get a quote

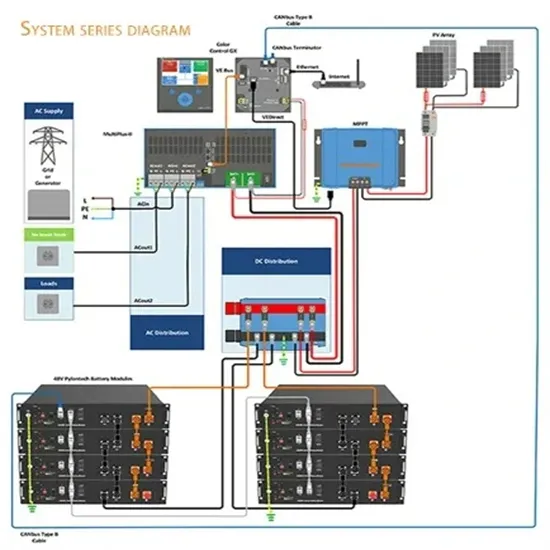

Bus Bar Design for High-Power Inverters

Index Terms—Bus bar, high-power inverter, power electronics, SRM inverter, stray capacitance, stray inductance, three-phase inverter. I. INTRODUCTION B US bars have been present in

Get a quote

Busbars in Solar Energy Systems | Redington Solar

Introduction Solar energy systems, particularly Busbars in Solar Energy Systems, have become increasingly popular due to their renewable nature and potential to reduce electricity costs.

Get a quote

The Critical Role of Busbars in Renewable Energy Applications

l Inverters: Inverters convert the collected DC into AC, which can then be fed into the grid or used on-site. Busbars help manage the input and output currents efficiently.

Get a quote

SolarEdge PCS Technology

Power Control Systems (PCS) help solar installers and homeowners install bigger systems, avoid main panel upgrades (MPU). PCS and Busbar Management actively control the current of the

Get a quote

2020 NEC 705 question | Information by Electrical Professionals

The PV AC disconnect itself is under 705.11, but the individual inverters on the busbar are all connected on the load side of the disco OCP, so 705.12 applies in the panel to

Get a quote

Residential Solar Interconnections (Full Guide)

A backfeed breaker can be used to connect a solar PV system to the load-side of a service. There are several different ways this can be done per the NEC but the most common method for

Get a quote

Solar Panel Busbars

In solar panels, busbars are the thin rectangular strips that separate solar cells and conduct electricity. It takes the electrons, once separated from photons by the solar cells, and

Get a quote

PCS Integration in Enphase Storage System

Main Panel Upgrade Avoidance: In many PV and storage systems, the Main Panel busbar rating at the site can be a limiting factor when adding a new Distributed Energy Resource (DER).

Get a quote

Solar Photovoltaic Systems, based on 2017 NEC

The busbar must have an ampacity of at least 125 percent of the PV system output circuit current rating, plus the rating of the overcurrent device protecting the busbar [705.12 (B) (2) (3) (a)].‚

Get a quote

SE-PCS-FAQs-Nov19-v002

A: The PCS feature does not increase system energy production. However, it enables the use of a larger PV system/inverter without MPUs, facilitating increased productivity and profitability. Q:

Get a quote

What is Busbar in Solar Cell? Explained Simply

A solar busbar is a thin strip of aluminum or copper that lies between cells in a panel. It separates cells and moves the direct current they create to the solar inverter.

Get a quote

6 FAQs about [Does the photovoltaic inverter have a busbar ]

What is a photovoltaic busbar?

A photovoltaic busbar is a special type of busbar for solar systems. It connects solar panels together. The busbar helps gather and send direct current from the solar panels to the inverter. This inverter changes the current to power we can use. The design of a solar panel is very important. It has to handle high voltages and not get too hot.

Are busbars bad for solar panels?

Another downside to more busbars is the soldering process. Sticking those strips of metal to the solar panel can create microcracks in the solar cells. The expanding and contracting strips of metal also cause movement within the solar panel that may increase the microcracks.

What is a busbar in a solar power system?

In the solar power system, the Busbar is made of silver-plated copper, responsible for collecting current from the photovoltaic cells on the battery panel and transmitting it to the inverter. The busbar can be placed on the front or back of the panel, depending on the manufacturer’s design. 3. Structure and operating principle of Busbar

Do IBC solar panels still have busbars and fingers?

As mentioned above, IBC solar panels still have busbars and fingers, but they’re placed behind the solar cells. A necessary part to keep the distribution of electricity efficient requires thinner busbars and solar cell fingers.

Why are solar cell busbars important?

In solar panels, busbars are wide. This helps them cool down quickly. They often connect to the solar panels through welding. And they’re protected in busways, with long busbars covered for safety. Solar cell busbars are very important in how well solar systems work. They help connect the solar panels.

How do you wire a busbar in a solar power system?

Wiring a busbar in a solar power system involves connecting the various components of the system, such as the solar panels, charge controller, and batteries, to the busbar. Here’s a general guide on how to wire a busbar: Mount the Busbar: First, mount the busbar on a non-conductive, fire-resistant surface.

Guess what you want to know

-

Photovoltaic cost-effective inverter

Photovoltaic cost-effective inverter

-

Nepal Smart Photovoltaic Inverter Project

Nepal Smart Photovoltaic Inverter Project

-

Single-module photovoltaic inverter

Single-module photovoltaic inverter

-

Photovoltaic power inverter manufacturers

Photovoltaic power inverter manufacturers

-

Danish photovoltaic power inverter

Danish photovoltaic power inverter

-

Vatican Photovoltaic Power Inverter Company

Vatican Photovoltaic Power Inverter Company

-

The role of photovoltaic solar inverter

The role of photovoltaic solar inverter

-

Palestine Photovoltaic Inverter Energy Storage Company

Palestine Photovoltaic Inverter Energy Storage Company

-

Balcony photovoltaic inverter

Balcony photovoltaic inverter

-

How big a solar panel does a 1kW photovoltaic inverter require

How big a solar panel does a 1kW photovoltaic inverter require

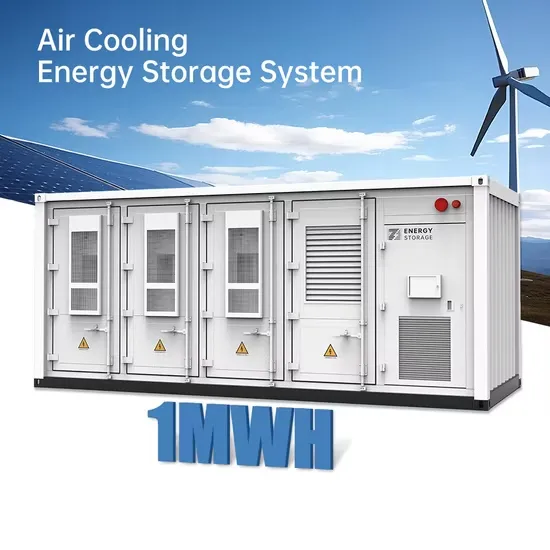

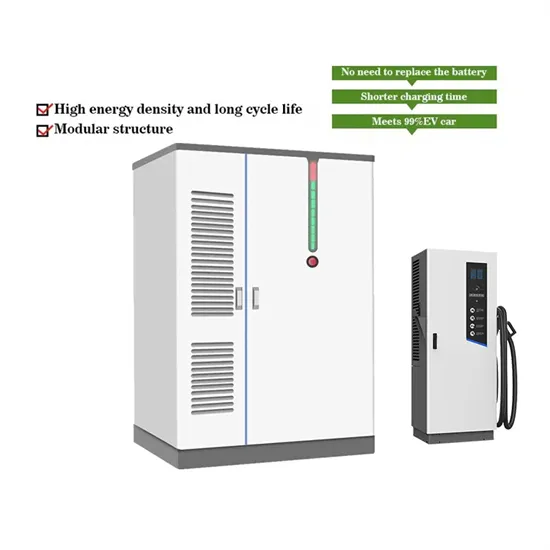

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

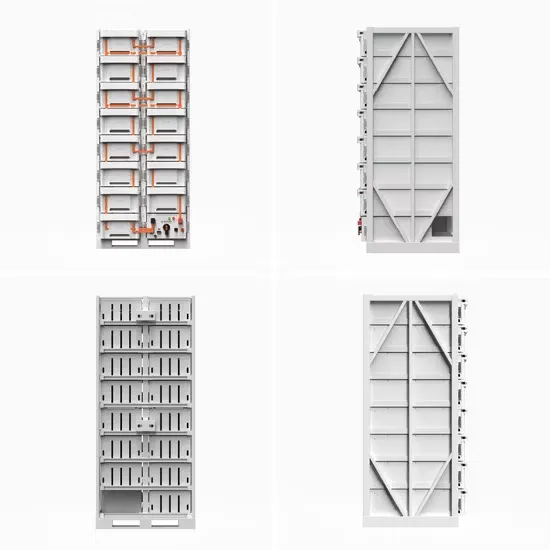

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.