Is 13.4 volts too high for devices requiring 12 V?

Some are available with a variable output voltage (so you can set it to exactly what you want) and others are completely fixed at 12v. It''s quite

Get a quote

Can I run 14 volts through a 12 volt LED Light strip without

Things that say 12V are usually designed to work with 12V lead-acid, car battery systems with voltages that can reach as high as 14.4V while the alternator is charging the

Get a quote

convert 14.4v DC to 12v DC : r/AskEngineers

First, check if your application can handle 14V? A couple extra volts won''t hurt most nominal 12V equipment. Battery voltage varies through the charge and discharge cycle anyways, for

Get a quote

Understanding Voltage Compatibility: 12V vs 14V

Using 12V in a 14V-required system may underpower it, while using 14V in a 12V system risks overvoltage stress. Proper voltage ensures

Get a quote

How bad, if at all, is 14.4V overvoltage for 12V inverter?

In general, 12v inverters will be ok with automotive voltages which can go up past 14.4volts. But you should always check the inverter (or any equipment) for their input voltage

Get a quote

Can I Charge a 14 Volt Battery with a 12V Charger?

No, you should not charge a 14V battery with a 12V charger—doing so risks undercharging, damage, or even failure. Many assume all chargers are interchangeable, but

Get a quote

Can I get a 14V output from a 12V transformer?

I want to use an LT3088 linear regulator at the transformer''s output to get a stable 12V. To do this, I must get around 14V at the ZA9672-BED

Get a quote

Understanding the Compatibility of 12V Solar Panels with 24V

While 12V batteries can be connected in parallel to increase capacity, 24V systems often connect batteries in series to achieve the required voltage levels. This series

Get a quote

Understanding Voltage Compatibility: 12V vs 14V Batteries

Using 12V in a 14V-required system may underpower it, while using 14V in a 12V system risks overvoltage stress. Proper voltage ensures safe operation, reliable performance,

Get a quote

12V DC to 14V DC adapter

Usually the straight 12v models are fine on a boat supply, but 14v models are generally safer as under voltage rarely causes any damage. Most 14v models will run fine on 12v.

Get a quote

Can I Attach My Small Inverter Directly to the Battery?

For example, a 12V inverter won''t work with a 24V battery bank; the excess voltage can instantly destroy the inverter''s circuitry. Conversely, a 24V inverter connected to a 12V

Get a quote

A Circuit Diagram for Converting 12v to 220v: Inverter

An inverter circuit diagram is essential for understanding how an inverter converts direct current (DC) to alternating current (AC) with the help of electronic

Get a quote

Easiest way to regulate a 12 V battery to regulated 12 V?

A fully charged 12V car battery measures about 13V, and with that voltage I''ve never damaged anything. I''ve also used 6V Lead batteries to replace 6V supply of my old Atari Lynx

Get a quote

Can I get a 14V output from a 12V transformer?

I want to use an LT3088 linear regulator at the transformer''s output to get a stable 12V. To do this, I must get around 14V at the ZA9672-BED (12V, 1A) thanks to the LT3088.

Get a quote

Can I Run a 12V Inverter on a 24V Battery?

You cannot connect a 12V inverter directly to a 24V battery because 12V inverters are only designed for 12V input, and 24V exceeds their operating range.

Get a quote

will 14.7 volts damage my 12v leds and other equipment?

My charge controller is set to recharge my battery bank and begin a float charge at 14.7 volts. If I use some of my 12 volt components during the day while the batteries are charging, will this

Get a quote

Can I get 14.4 volts from a 12v li-ion battery?

It''ll run off my 12-volt lithium-ion portable battery, but the functionality is compromised. I can connect the CPAP''s AC power cord to an inverter and power the inverter

Get a quote

12 Volt DC Power Inverter: In-Depth Learning and

By choosing Topbull''s 12V DC power inverters, you can ensure long-lasting and safe operation of your devices, regardless of the power

Get a quote

How can I step up from 12V to 14V for about 80 W?

There is no way to efficiently convert 12V DC to 14V DC at 3.5A without using some kind of switching circuits - by the time you add all the necessary protection and emc precautions it

Get a quote

convert 14.4v DC to 12v DC : r/AskEngineers

First, check if your application can handle 14V? A couple extra volts won''t hurt most nominal 12V equipment. Battery voltage varies through the charge and discharge cycle

Get a quote

How Many Lights Can I Connect To My Transformer?

Low voltage lighting is a great way to add style and ambience to any outdoor setting, and with the right transformer, it can be done safely and

Get a quote

Is 13.4 volts too high for devices requiring 12 V?

Some are available with a variable output voltage (so you can set it to exactly what you want) and others are completely fixed at 12v. It''s quite simple (with a little experience

Get a quote

Can I run 14 volts through a 12 volt LED Light strip without

Things that say 12V are usually designed to work with 12V lead-acid, car battery systems with voltages that can reach as high as 14.4V while the alternator is charging the battery. My

Get a quote

6 FAQs about [Can a 12v inverter be connected to a 14v voltage ]

What is the difference between a 12V and 14v battery?

A 12V battery typically operates at a nominal voltage of around 12.6 volts when fully charged, while a 14V battery usually indicates its charging state, often reaching up to 14.4 to 14.7 volts during charging. This difference is essential for understanding how each type functions within electrical systems.

How many volts does a 12V battery charge?

A 12V charger typically outputs around 13.8 to 14.4 volts during the charging cycle to ensure that a 12V battery reaches full capacity without overcharging.For systems utilizing 14V batteries, chargers must be able to maintain higher voltages during operation to ensure proper charging cycles without damaging connected devices.

Can a 12 volt battery be used as a power supply?

Most mounts and other astro equipment that are built to use nominal 12V lead acid batteries as power supplies will work fine with the 13.8V regulated power supplies. The no load voltage on a fully charged lead acid battery is about 13.2V. Most of the power supplies sold for astronomy equipment applications are in the 13 to 14 volt range.

What voltage range can a 12V battery handle?

A 12V battery can handle a reasonable range of voltages. It's not uncommon for power supplies designed to replace a 12V battery to put out 13+ volts, even the regulated ones.

What is the typical voltage range for 12V compatible products?

Since 12v battery voltages can actually vary a bit, virtually all 12v compatible products can handle a reasonable range of voltages. It's not uncommon for power supplies designed to replace a 12v battery to put out 13+ volts even the regulated ones.

What voltage does a 12 volt alternator produce?

Don't forget that the alternator output on your car typically runs at 13.5 - 14.3V to keep your '12V' battery charged. Most listed 12 volts electronic equipment are rated around 14.5 vdc max. When your vehicle engine is on, the voltage could be as high as 14.5 vdc.

Guess what you want to know

-

The inverter can be directly connected to 12v

The inverter can be directly connected to 12v

-

Can 1000V solar panels be connected to a 12V water pump inverter

Can 1000V solar panels be connected to a 12V water pump inverter

-

12v 10a connected to 220 inverter

12v 10a connected to 220 inverter

-

Inverter marked voltage 12v

Inverter marked voltage 12v

-

High voltage battery connected to inverter

High voltage battery connected to inverter

-

12v high voltage pulse inverter

12v high voltage pulse inverter

-

60V inverter connected to 12v

60V inverter connected to 12v

-

Can a 12v lithium battery be directly connected to an inverter

Can a 12v lithium battery be directly connected to an inverter

-

Can a 12v home inverter be connected to 18 volts

Can a 12v home inverter be connected to 18 volts

-

Single voltage closed loop inverter

Single voltage closed loop inverter

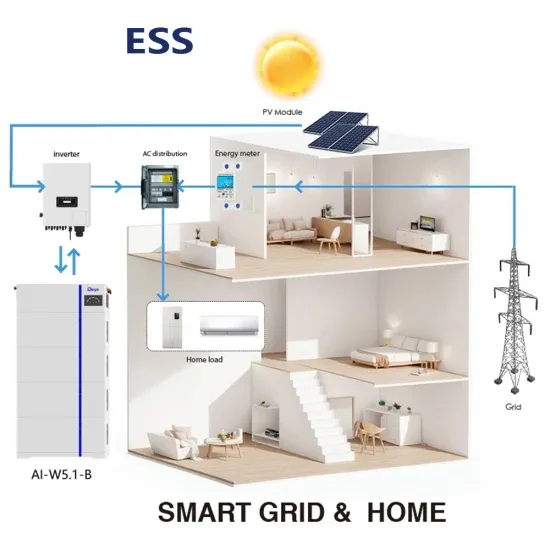

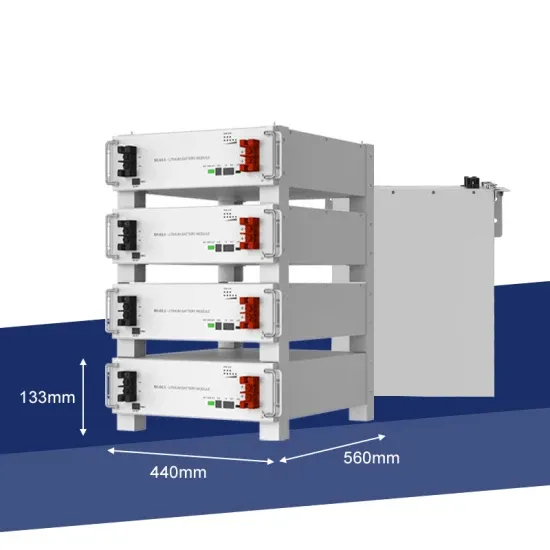

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

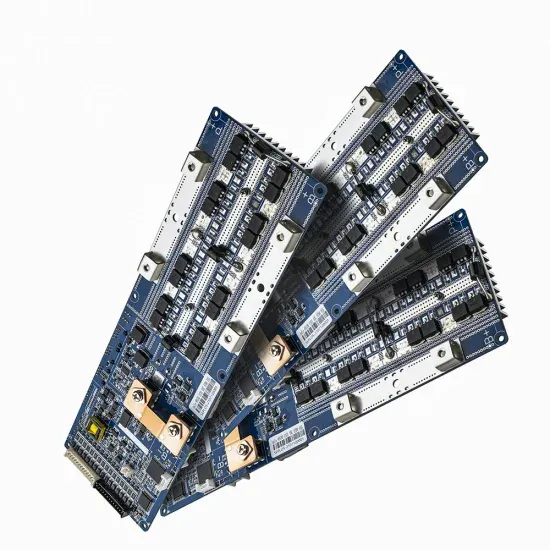

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.