Bridging the fire protection gaps: Fire and explosion risks in grid

Techniques for explosion mitigation include vent gas characterization and full-scale testing, while fire mitigation involves active suppression systems or passive exposure protection.

Get a quote

Four Overlooked BESS Project Requirements

Fire is a risk for all energy projects and continues to be a point of emphasis with AHJs and other permitting authorities. Since BESS technology is so new, code requirements,

Get a quote

Proactive First Responder Engagement for Battery Energy

Entergy''s Risk Management Fire Protection Engineers are engaged in the conceptual design aspects of all BESS projects. This ensures that related fire risks are adequately addressed

Get a quote

Bridging the fire protection gaps: Fire and explosion

Introduction The challenges of providing effective fire and explosion hazard mitigation strategies for Battery Energy Storage Systems

Get a quote

What are the fire protection requirements for energy storage

Fire protection requirements for energy storage equipment include: compliance with national and local codes, installation of appropriate fire suppression systems, continuous

Get a quote

Managing fire risk Battery Energy Storage System

This fact sheet outline the measures we take to reduce the risk of a fire at our BESS facilities, and highlights the many ways that fire risk management is considered within the project''s life-cycle.

Get a quote

Fire protection management measures for new energy

In 2019, EPRI began the Battery Energy Storage Fire Prevention and Mitigation - Phase I research project, convened a group of experts, and conducted a series of energy storage site

Get a quote

Battery Energy Storage Systems (BESS)

4 National Fire Protection Association, Battery Energy Storage Hazards and Failure Modes, December 3, 2021. white paper, "Laying the Foundation."5 In particular, CanREA recognizes

Get a quote

Fire Codes and NFPA 855 for Energy Storage Systems

Fire codes and standards inform energy storage system design and installation and serve as a backstop to protect homes, families, commercial facilities, and personnel,

Get a quote

Moss Landing fire prompts ACP to publish BESS Safety Blueprint

Large-scale battery fires are a hot topic, especially since the Moss Landing fire. To help industry ensure best practices for lithium-ion-based battery energy storage (BESS)

Get a quote

Energy Storage in New York City

In contrast, all energy storage systems authorized for installation in New York must have undergone many stages of rigorous safety testing (e.g. UL certification), have required project

Get a quote

BATTERY STORAGE FIRE SAFETY ROADMAP

This roadmap provides necessary information to support owners, opera-tors, and developers of energy storage in proactively designing, building, operating, and maintaining these systems to

Get a quote

Bridging the fire protection gaps: Fire and explosion

Techniques for explosion mitigation include vent gas characterization and full-scale testing, while fire mitigation involves active

Get a quote

Fire Safety Solutions for Energy Storage Systems | EB BLOG

Explore advanced fire safety solutions for energy storage systems, including fire suppression techniques and innovative technologies to protect personnel and equipment.

Get a quote

Understanding NFPA 855: Fire Protection for Energy

As energy storage systems become increasingly integral to the energy grid, it''s essential that fire safety remains a top priority. NFPA 855

Get a quote

Fire Suppression for Battery Energy Storage Systems

As demand for electrical energy storage systems (ESS) has expanded, safety has become a critical concern. This article examines lithium

Get a quote

Battery Energy Storage Systems: Main Considerations for Safe

This webpage includes information from first responder and industry guidance as well as background information on battery energy storage systems (challenges & fires), BESS

Get a quote

Understanding NFPA 855: Fire Protection for Energy Storage

As energy storage systems become increasingly integral to the energy grid, it''s essential that fire safety remains a top priority. NFPA 855 provides a comprehensive

Get a quote

SAN DIEGO COUNTY FIRE PROTECTION DISTRICT

II. BACKGROUND The San Diego County Fire Protection District (SDCFPD) currently employs a mix of local, state, and national codes and standards to review Battery Energy Storage System

Get a quote

Fire Safety Solutions for Energy Storage Systems

Explore advanced fire safety solutions for energy storage systems, including fire suppression techniques and innovative technologies to protect

Get a quote

After a High-Profile Fire, Battery Energy Storage

A clean-energy trade group''s report offers safety guidelines for battery energy storage systems following a fire at one of the largest battery

Get a quote

How Advanced Solar Energy Management Systems Prevent

Fires, overheating, and system failures can pose serious risks, especially in large-scale solar installations. Traditional Energy Management Systems (EMS) mainly track energy

Get a quote

Fire management of new energy storage projects

These initiatives have included creating a battery storage fire safety roadmap,developing recommendations and leading practices for designing systems,and training and working with

Get a quote

6 FAQs about [Fire protection management for new energy storage projects]

What are the fire and building codes for energy storage systems?

However, many designers and installers, especially those new to energy storage systems, are unfamiliar with the fire and building codes pertaining to battery installations. Another code-making body is the National Fire Protection Association (NFPA). Some states adopt the NFPA 1 Fire Code rather than the IFC.

What is an energy storage roadmap?

This roadmap provides necessary information to support owners, opera-tors, and developers of energy storage in proactively designing, building, operating, and maintaining these systems to minimize fire risk and ensure the safety of the public, operators, and environment.

What is battery energy storage fire prevention & mitigation?

In 2019, EPRI began the Battery Energy Storage Fire Prevention and Mitigation – Phase I research project, convened a group of experts, and conducted a series of energy storage site surveys and industry workshops to identify critical research and development (R&D) needs regarding battery safety.

Why are building and fire codes important?

Before diving into the specifics of energy storage system (ESS) fire codes, it is crucial to understand why building and fire codes are so relevant to the success of our industry. The solar industry is experiencing a steady and significant increase in interest in energy storage systems and their deployment.

What happened at Gateway energy storage facility?

On May 15, 2024, Gateway Energy Storage Facility in San Diego, California, experienced a BESS fire with continued flare-ups for seven days following the fire. The facility held about 15,000 nickel manganese cobalt lithium-ion batteries.

Are there any problems with energy storage?

There have also been issues in the U.S. residential energy storage sector. For example, after five reported fires stemming from its RESU10 battery units, LG Chem issued product recalls in December of 2020 and again in August 2021. According to the Consumer Product Safety Commission, these fires resulted in property damage and one injury.

Guess what you want to know

-

Fire protection design for new energy storage projects

Fire protection design for new energy storage projects

-

Energy Storage Projects and Fire Protection

Energy Storage Projects and Fire Protection

-

Let new energy storage projects improve both quantity and quality

Let new energy storage projects improve both quantity and quality

-

New energy projects equipped with energy storage

New energy projects equipped with energy storage

-

Energy storage allocation for new energy projects

Energy storage allocation for new energy projects

-

New Energy Storage System Management

New Energy Storage System Management

-

A batch of new energy storage projects in Russia

A batch of new energy storage projects in Russia

-

The first batch of new energy storage projects in Tartu Estonia

The first batch of new energy storage projects in Tartu Estonia

-

Bhutan s latest policy on new energy storage

Bhutan s latest policy on new energy storage

-

Engineering Energy Storage New Energy Manufacturer

Engineering Energy Storage New Energy Manufacturer

Industrial & Commercial Energy Storage Market Growth

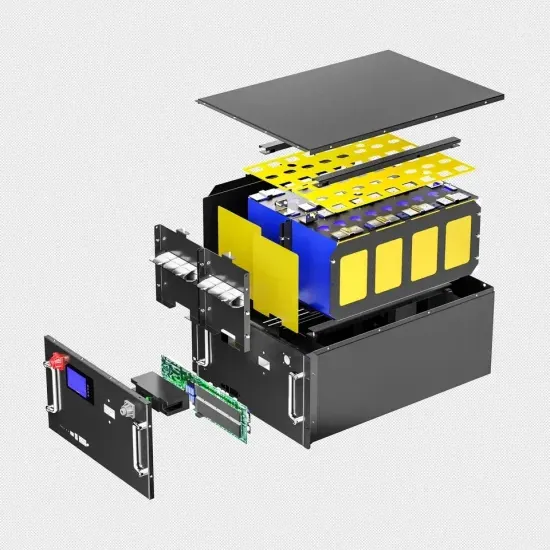

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.