Energy Storage Solution LFP Battery System

Optimizing Energy Storage Systems Under Minimal Risk Delta''s battery storage systems feature high-voltage output for enhanced energy management efficiency. With their scalable, fire

Get a quote

A reliability review on electrical collection system of battery energy

This paper''s literature investigation can provide a support for the reliability improvement of energy storage power station.

Get a quote

Modeling and Simulation of Battery Energy Storage Systems

Plant controller module (REPC_A) – This module processes frequency and active power output of the BESS to emulate frequency/active power control. It also processes voltage and reactive

Get a quote

StackRack Battery Systems | Residential, Commercial

Achieve grid independence by generating, storing, and using your own energy, safeguarding against costly utility rates and future increases. Our commercial

Get a quote

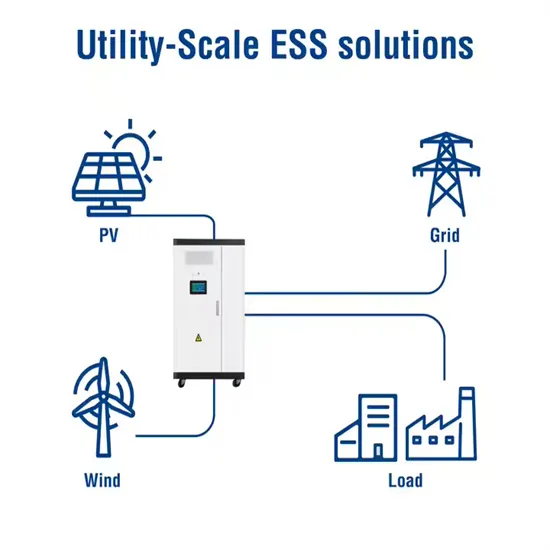

Utility-scale battery energy storage system (BESS)

This reference design focuses on an FTM utility-scale battery storage system with a typical storage capacity ranging from around a few megawatt-hours (MWh) to hundreds of MWh.

Get a quote

Analysis on Self-heating Process of Battery Modules in Energy

The safety of battery modules in energy storage station is a key factor for the power system with high proportion of renewable energy. In this study, the therma.

Get a quote

Modeling and validation of battery energy storage systems using

The model is benchmarked against a detailed 3-phase equipment specific model. The paper may also be downloaded for free from the source CIGRE.

Get a quote

Battery energy storage system modeling: A combined

In this work, a new modular methodology for battery pack modeling is introduced. This energy storage system (ESS) model was dubbed hanalike after the Hawaiian word for "all

Get a quote

China Energy Transition Review 2025

As academic conclusions frequently inform government modelling, there is a risk that governments may also overestimate energy transition costs by relying on outdated figures for

Get a quote

Handbook on Battery Energy Storage System

One energy storage technology in particular, the battery energy storage system (BESS), is studied in greater detail together with the various components required for grid-scale operation.

Get a quote

Study on Modeling Energy Storage Battery Module Based on the

Parameter estimation of battery module in energy storage stations is fundamental for battery management and fault diagnosis. This paper proposes a battery module model

Get a quote

Explosion hazards study of grid-scale lithium-ion battery energy

Here, experimental and numerical studies on the gas explosion hazards of container type lithium-ion battery energy storage station are carried out. In the experiment, the LiFePO4

Get a quote

Modeling and validation of battery energy storage

The model is benchmarked against a detailed 3-phase equipment specific model. The paper may also be downloaded for free from the source

Get a quote

What are the energy storage module models?

They help ensure that energy is available even when production is low, thus supporting the reliability and resilience of the energy supply. In the

Get a quote

Electro-thermal coupling modeling of energy storage station

Aiming at the current lithium-ion battery storage power station model, which cannot effectively reflect the battery characteristics, a proposed electro-thermal coupling modeling method for

Get a quote

Reliability Assessment of Battery Energy-Storage Module Based

The battery energy storage technology can be flexibly configured and has excellent comprehensive characteristics. In addition to considering the reliability of the battery energy

Get a quote

What are the energy storage module models? | NenPower

They help ensure that energy is available even when production is low, thus supporting the reliability and resilience of the energy supply. In the following sections, various

Get a quote

Battery Energy Storage System Evaluation Method

Executive Summary This report describes development of an effort to assess Battery Energy Storage System (BESS) performance that the U.S. Department of Energy (DOE) Federal

Get a quote

WECC Battery Storage Guideline

This guideline focuses only on transient stability dynamic models of battery energy storage systems (BESS) which is one of many energy storage technologies widely adopted in the

Get a quote

Battery Energy Storage Systems (BESS)

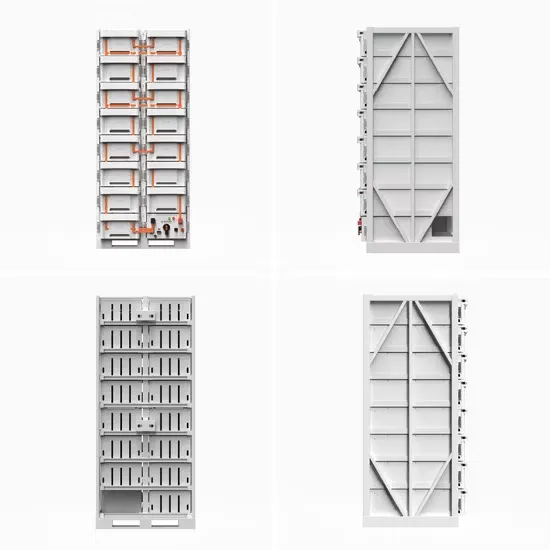

The state- of-the-art facility features a purpose-built area for the assembly and testing of extensive industrial controls and automation systems, Battery Energy Storage Systems (BESS), and

Get a quote

Multi-Level Thermal Modeling and Management of

This study employs the isothermal battery calorimetry (IBC) measurement method and computational fluid dynamics (CFD) simulation to

Get a quote

Multi-Level Thermal Modeling and Management of Battery Energy Storage

This study employs the isothermal battery calorimetry (IBC) measurement method and computational fluid dynamics (CFD) simulation to develop a multi-domain thermal

Get a quote

Energy Storage Valuation: A Review of Use Cases and Modeling

Disclaimer This report was prepared as an account of work sponsored by an agency of the United States government. Neither the United States government nor any agency thereof, nor any of

Get a quote

Base Station Energy Storage

MANLY Main Base Station Energy Storage LiFePO4 Battery Module A. The above tables are all equipped with communication protocols. According to your needs, whether you need a

Get a quote

Analysis on Self-heating Process of Battery Modules in Energy Storage

The safety of battery modules in energy storage station is a key factor for the power system with high proportion of renewable energy. In this study, the therma.

Get a quote

6 FAQs about [Energy storage station battery module model]

What is connection form of collection system of battery energy storage power station?

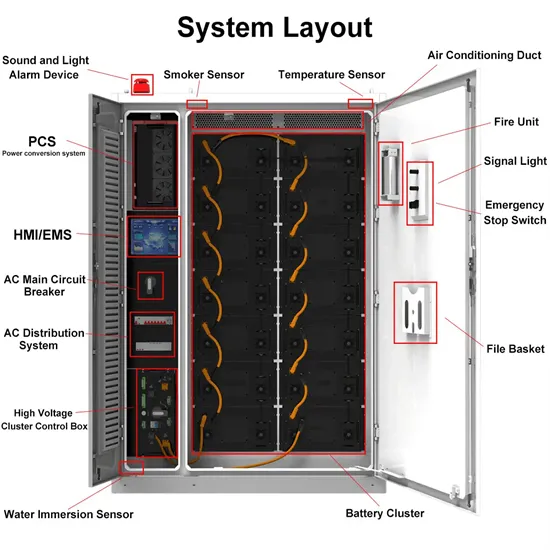

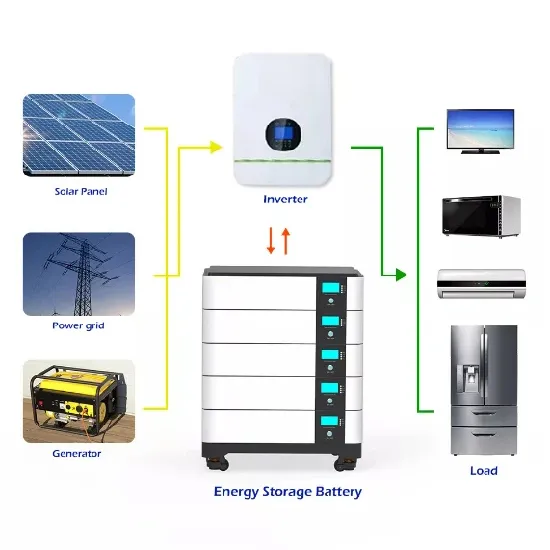

Connection form of collection system of battery energy storage power station The energy storage system is mainly composed of energy storage battery pack, power conversion system (PCS), battery management system (BMS), battery monitoring system (MNS) and other subsystems .

What is a battery energy storage system (BESS)?

Battery energy storage systems (BESS) are increasingly gaining traction as a means of providing ancillary services and support to the grid. This is particularly true in micro-grids and in supplement with photovoltaic (PV) generation. As such, for power system time-domain simulation studies, standard models are needed for modeling BESS.

What is battery energy storage system?

The battery energy storage system is a flexible resource with dual characteristics of source and load. It can be widely used in renewable energy consumption, peak shaving and frequency modulation, virtual power plant, and so on.

What is the scale of energy storage battery pack?

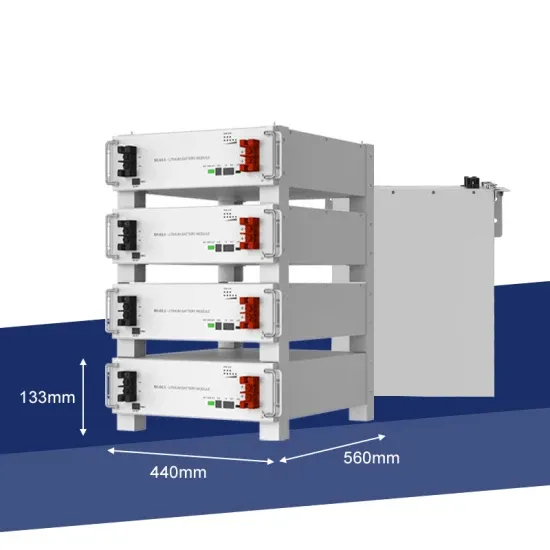

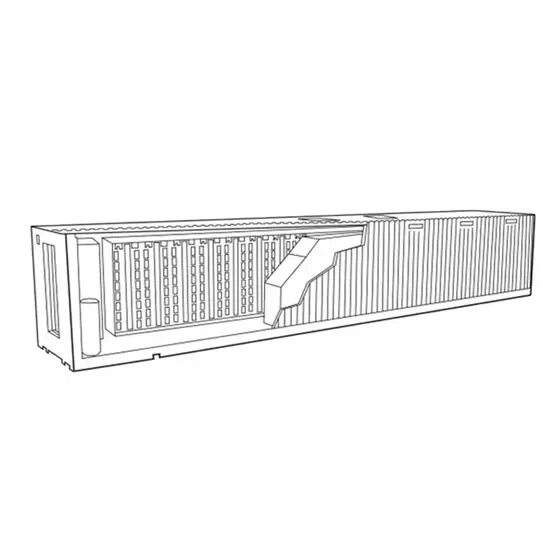

As shown in Fig. 1, the scale of energy storage battery pack from small to large is single battery (cell), battery module, battery cluster, battery system, etc., while the energy storage battery pack is composed of single batteries in series and parallel and connected to the power grid through the power conversion system.

Can a large-scale battery energy storage system be dynamically represented?

Dynamic representation of a large-scale battery energy storage system for system planning studies requires the use of two or three new renewable energy (RE) modules shown below in Figure 4 . These modules, in addition to others, are also used to represent wind and PV power plants.

How many battery energy storage systems are there?

Currently, approximate 70 battery energy storage systems with power ratings of 1 MW or greater are in operation around the world. With more and more large-scale BESS being connected to bulk systems in North America, they play an important role in the system reliability.

Guess what you want to know

-

Battery Energy Storage Power Station Solution

Battery Energy Storage Power Station Solution

-

Vanuatu base station energy storage battery brand

Vanuatu base station energy storage battery brand

-

Nicaragua Distributed Energy Storage Power Station Model

Nicaragua Distributed Energy Storage Power Station Model

-

Tuvalu communication base station energy storage battery installation

Tuvalu communication base station energy storage battery installation

-

Energy storage lithium iron phosphate battery station cabinet

Energy storage lithium iron phosphate battery station cabinet

-

Brazilian energy storage cabinet battery company introduces base station

Brazilian energy storage cabinet battery company introduces base station

-

Photovoltaic energy storage cabinet lithium battery base station

Photovoltaic energy storage cabinet lithium battery base station

-

Energy storage container battery module installation site

Energy storage container battery module installation site

-

What is the capacity of the BESS model of the energy storage power station

What is the capacity of the BESS model of the energy storage power station

-

Communication base station energy storage battery installation location

Communication base station energy storage battery installation location

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.