Sodium Pyroantimonate Nasbo3 CAS No 12507-68-5 for Photovoltaic Solar

Sodium Pyroantimonate Nasbo3 CAS No 12507-68-5 for Photovoltaic Solar Glassflame Retardant Sodium Antimonate Powder, Find Details and Price about Sodium Salt and Nasbo3 from

Get a quote

Sodium pyroantimonate-Sodium pyroantimonate-Products Center

Sodium pyroantimonate is mainly used as clarifying agent for picture tube glass, optical glass and other glass, also used in enamel, ceramics and flame retardant industries. 1, photovoltaic solar

Get a quote

Sodium pyroantimonate

sodium pyroantimonate is used as a glass fining agent in the production of high-grade glass such as solar glass, and can also be used as a flame retardant synergist for

Get a quote

High Fusing Point Sodium Pyroantimonate for Photovoltaic Solar

MAIN PURPOSESodium antimonate is mainly used as a clarifying agent and defoamer for photo-voltaic solar glass, black and white, and color display screen cathode ray tube glass.

Get a quote

Most photovoltaic glass companies choose sodium

In the glass manufacturing industry, sodium pyroantimonate and antimony trioxide is also used to manufacture a variety of properties and uses of glass, such as optical glass, infrared

Get a quote

How is Solar Glass Different from Other Types of Glass?

Among the primary elements of solar glass are quartz sand, soda ash, limestone, dolomite, sodium nitrate, mirabilite, sodium pyroantimonate, aluminum hydroxide, and so on.

Get a quote

Sodium Pyroantimonate: A High-Performance Alternative to

Sodium antimonate has a much lower tinting strength than antimony trioxide, along with lower arsenic and lead content, making it superior for use as a low-tinting flame

Get a quote

A Summary of Smelting and Secondary Recovery Process of

As Fig. 3 shows, the aforementioned three groups are also used for various other applications. First, sodium pyroantimonate, with a mixing quality of 0.2% to 0.4%, is typically

Get a quote

Sodium pyroantimonate

Use spark-proof tools and explosion-proof equipment. Adhered or collected material should be promptly disposed of, in accordance with appropriate laws and regulations.

Get a quote

Sodium Antimonate Powder Sodium Pyroantimonate

Sodium Antimonate Powder Sodium Pyroantimonate and Nasb (OH) 6 with CAS No 12507-68-5, Find Details and Price about Sodium Antimonate 12507-68-5

Get a quote

Addressing uncertain antimony content in solar glass for

An mony compounds (an mony trioxide, Sb2O3, or sodium an monate NaSbO3) are added to a batch, at the 0.1—1 wt% level, to increase light transmission in paterned solar glass. An mony

Get a quote

How is Solar Glass Different from Other Types of Glass?

Among the primary elements of solar glass are quartz sand, soda ash, limestone, dolomite, sodium nitrate, mirabilite, sodium pyroantimonate, aluminum

Get a quote

Sodium pyroantimonate | 12507-68-5

ChemicalBook あなたのためにSodium pyroantimonate (12507-68-5)の化学的性質を提供して、融点、価格、蒸気圧、沸点、毒性、比重、沸点、密度、分子式、分子量、物理的な性質、毒性

Get a quote

Solar Panel Cleaning: Best Practices and Simple Guide

Dirty panels? There are some instances where solar panels might need cleaning, but most of the evidence says solar panels are self-sufficient

Get a quote

Sodium Antimonate pyroantimonate,cas 12507-68-5 | Baoxu chem

Sodium pyroantimonate is primarily used as a clarifier and defoamer for photovoltaic solar glass and kinescope glass for black and white and color display screens. It is also used as a clarifier

Get a quote

Sodium pyroantimonate | 31589-39-6

Visit ChemicalBook To find more Sodium pyroantimonate (31589-39-6) information like chemical properties,Structure,melting point,boiling point,density,molecular formula,molecular weight,

Get a quote

Solar Glass: What Is It & What Is Its Role In Solar Panels?

The function of solar glass in solar panels is to protect solar panels from water vapor erosion, block oxygen to prevent oxidation, so that solar panels can withstand high and

Get a quote

MONOGRAPHS (USP)

Potassium pyroantimonate solution—Dissolve 2 g of po-tassium pyroantimonate in 95 mL of hot water. Cool quick-ly, and add a solution containing 2.5 g of potassium hydroxide in 50 mL of

Get a quote

Most photovoltaic glass companies choose sodium pyroantimonate

In the glass manufacturing industry, sodium pyroantimonate and antimony trioxide is also used to manufacture a variety of properties and uses of glass, such as optical glass, infrared

Get a quote

Are Solar Panels Are Filled with Toxic Chemicals that Leach Into

Research published in the Journal of Hazardous Materials in 2017 found that it''s possible to release the trace amounts of cadmium in a solar panel – but to do so, you''d first

Get a quote

6 FAQs about [Solar panels use sodium pyroantimonate]

What is sodium pyroantimonate used for?

sodium pyroantimonate is white or off-white crystalline powder, soluble in hot water, insoluble in cold water, insoluble in ethanol. sodium pyroantimonate is used as a glass fining agent in the production of high-grade glass such as solar glass, and can also be used as a flame retardant synergist for plastics and rubber.

Why do solar panels use borosilicate glass?

Solar glass manufacturers in India and elsewhere prefer using borosilicate glass because it is lightweight and sturdy, which facilitates installation and increases the overall efficiency of solar panels. Ideal for settings with unpredictable weather, borosilicate glass is capable of handling rapid temperature fluctuations without breaking.

Why do solar panels have a low iron concentration?

One key is their solar glass with low iron concentration. Ordinary glass absorbs sunlight due to its higher iron content. This absorption reduces light reaching the solar cells, lowering solar panel efficiency. However, solar glass has less iron. Less light absorption allows more sunlight to reach the solar cells via the glass.

Is tempered glass a good material for solar panels?

Tempered glass has long been the go-to material for solar panels due to its affordability and popular use. The solar glass that has undergone a specific heat treatment technique is much more durable than ordinary glass. It can resist hail and strong winds, among other severe weather events.

What type of glass do solar panels use?

Solar panels usually use plate glass, which is the most basic type of glass. It’s pretty flat, see-through, and lets a fair amount of light in. On the other hand, it’s not as durable or unique as some other solar panel glass choices. They are inexpensive to produce. Therefore, they are the cost-effective option for basic solar panel applications.

Why are solar panels packaged with glass?

Therefore, solar cells are usually packaged with solar glass through EVA and back sheet. The function of solar glass in solar panels is to protect solar panels from water vapor erosion, block oxygen to prevent oxidation, so that solar panels can withstand high and low temperature, have good insulation and aging resistance.

Guess what you want to know

-

Use of bifacial solar panels in Croatia

Use of bifacial solar panels in Croatia

-

How to use solar panels to generate energy on site

How to use solar panels to generate energy on site

-

How to use container solar panels site

How to use container solar panels site

-

Rural solar photovoltaic panels for household use 220v

Rural solar photovoltaic panels for household use 220v

-

Home solar photovoltaic panels for daytime use

Home solar photovoltaic panels for daytime use

-

Use of 20W solar panels in Dominica

Use of 20W solar panels in Dominica

-

How much does solar power generation cost for home use

How much does solar power generation cost for home use

-

Photovoltaic solar panels connected to solar integrated machine

Photovoltaic solar panels connected to solar integrated machine

-

Cambodia s new solar photovoltaic panels

Cambodia s new solar photovoltaic panels

-

Is Montenegro exempt from tariffs on solar panels

Is Montenegro exempt from tariffs on solar panels

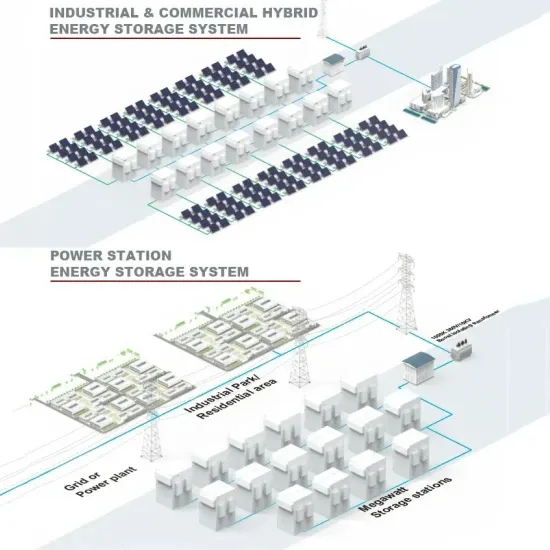

Industrial & Commercial Energy Storage Market Growth

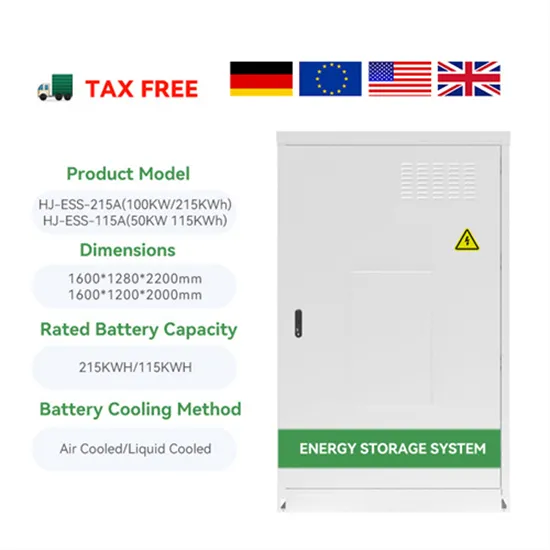

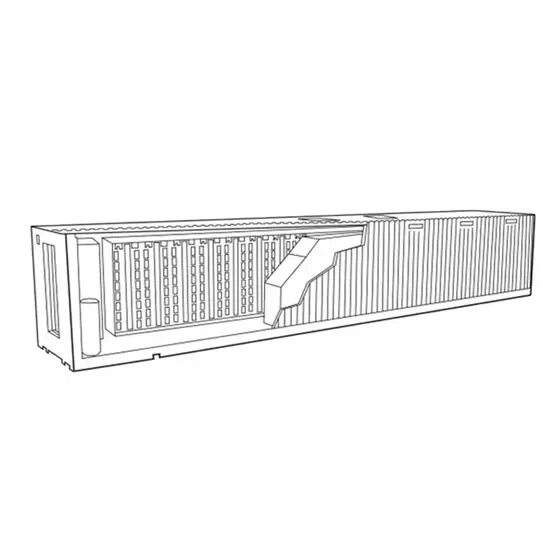

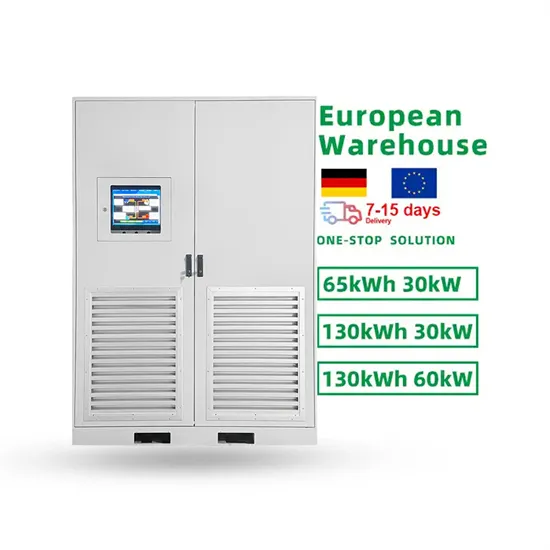

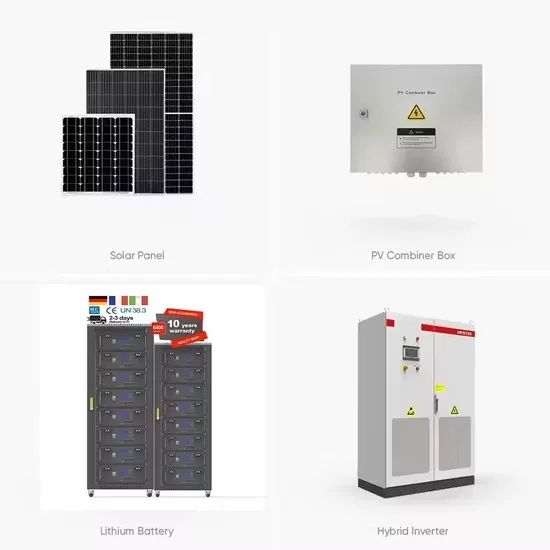

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

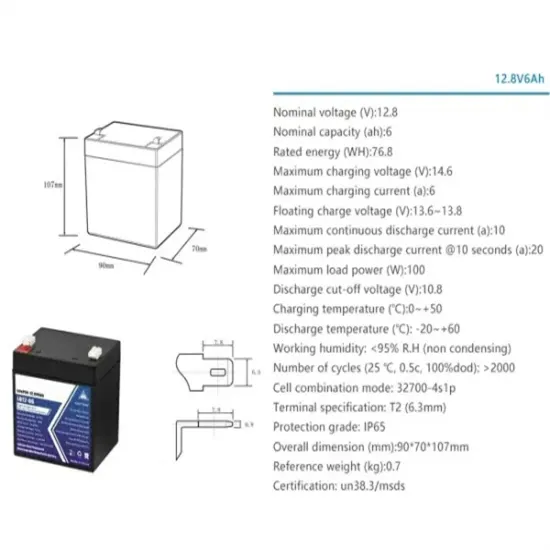

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.