6 Battery Energy Storage Systems — Lithium | UpCodes

This section applies to battery energy storage systems that use any lithium chemistry (BESS-Li). Unoccupied structures housing BESS-Li must comply with NFPA 855, except where modified

Get a quote

Finding the Perfect Space: How Much Room Should Be Between

When designing and organizing your kitchen, various factors contribute to a functional and appealing layout. One crucial consideration is the amount of space you keep

Get a quote

IFC Mounting Requirements for IQ Battery Systems

The UL 9540A testing shows that the manufacturers installation and spacing recommendations included in these products'' Quick Installation Guides (QIG) are adequate

Get a quote

How Much Space Between Stove And Cabinet? | Safe

How Much Space Between Stove And Cabinet: A Comprehensive Guide 🍳 When designing or remodeling a kitchen, one crucial question often arises: "How

Get a quote

Spaces About Battery Systems | UpCodes

Spaces designated for battery systems must adhere to specific regulations regarding working space, which is measured from the battery cabinet''s edge. For battery racks, a minimum

Get a quote

Battery Cabinet

To check for inadvertent grounding of the battery, use a digital multi-meter set to the DC Volts scale to measure the voltage between any battery terminal and either the cabinet framework

Get a quote

Work Space about battery racks | Information by Electrical

Batteries should be located in clean, dry rooms and be arranged to provide sufficient work space for inspection and maintenance. Provisions must also be made for

Get a quote

EG4 BESS Spacing

The following document clarifies BESS (Battery Energy Storage System) spacing requirements for the EG4 WallMount batteries / rack mount six slot battery cabinet installations.

Get a quote

Equipment layout and clearances

The cabinets may be placed with zero clearance to the rear wall. The cabinets may be placed with zero clearance to the side wall, however some clearance

Get a quote

Guidelines for storage & usAGE of lead acid batteries

2 Lead-Acid Batteries Lead-acid batteries are the most widely used electrical energy storage, primarily for uninterrupted power supply (UPS) equipment and emergency power system

Get a quote

Do Server Rack Batteries need space between them?

I placed my two racks symmetrically in the space between panels, supply (left), load (right) to reduce the wiring size. All of my main rack 4/0 wiring from server to combiner

Get a quote

Control Panel Layout And Wiring Best Practices

The quality of the wiring methods used in an industrial control panel can vary quite widely. This article summarizes what this author believes are some best practice when it comes to control

Get a quote

Designing Industrial Battery Rooms: Fundamentals and Standards

Industrial battery rooms require careful design to ensure safety, compliance, and operational efficiency. This article covers key design considerations and relevant standards.

Get a quote

Cabinet and rack which one is better for Li-ion battery

Cabinets offer safety and protection for Li-ion battery packs, while racks provide scalability and flexibility. Choose based on space, cooling, and

Get a quote

What is the appropriate safety distance between battery

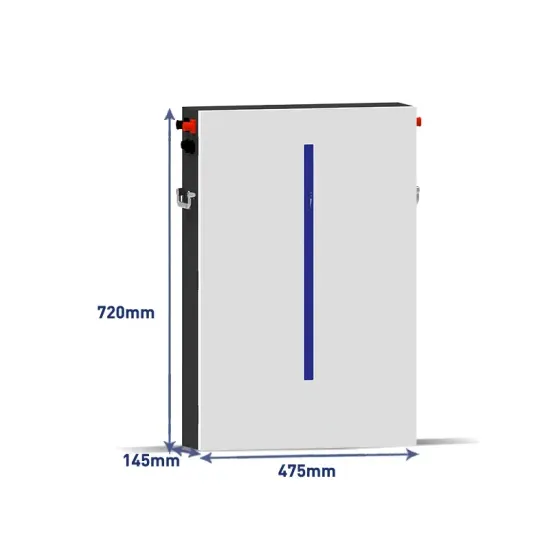

The space requirements for battery systems must comply with 110.26. Working space is measured from the edge of the battery cabinet,racks,or trays. For battery racks,there is a

Get a quote

480.9 Battery Locations.

Working space shall be measured from the edge of the battery cabinet, racks, or trays. For battery racks, there shall be a minimum clearance of 25 mm (1 in.) between a cell container and any

Get a quote

What is the best storage spacing for energy storage

Determining the optimal storage spacing for energy storage cabinets is paramount. The effectiveness, safety, and longevity of the battery

Get a quote

B-type equipment room battery cabinet spacing

This article does not cover maintenance free or computer room type batteriesand battery cabinets in its Battery Room Design Requirements. The main keywords for this article are vented lead

Get a quote

What is the best storage spacing for energy storage cabinets?

Determining the optimal storage spacing for energy storage cabinets is paramount. The effectiveness, safety, and longevity of the battery systems depend heavily on how these

Get a quote

What is the appropriate safety distance between battery

Batteries themselves should be mounted on stands or in cabinets, designed to provide good access, particularly to prevent personnel responsible for servicing from having to

Get a quote

Essential Requirements for Placing Energy Storage Batteries: A

The secret often lies in how and where you place those battery units. Whether you''re setting up a home solar system or managing a commercial energy park, understanding

Get a quote

6 FAQs about [Spacing between battery cabinets]

How much space do you need for a battery system?

Spaces about battery systems shall comply with 110.26. Working space shall be measured from the edge of the battery cabinet, racks, or trays. For battery racks, there shall be a minimum clearance of 25 mm (1 in.) between a cell container and any wall or structure on the side not requiring access for maintenance.

How far apart should IQ batteries be stacked?

Enphase IQ Battery 3, 3T, 10, and 10T test was conducted at the manufacturers recommended mounting distances with a minimum of 6” between vertically stacked units, 1” horizontally between IQ Battery 3/3T, and 6” clearance on the sides for IQ Battery 10/10T. The IQ Battery datasheets detail that they have been certified to UL9540A.

How much space is required between IQ batteries?

The following diagrams illustrate the minimum amount of space required between each IQ Battery. The minimum space for non-battery Enphase equipment is 6” around all sides. For first-generation wall mounts that are not UL 9540A compliant. The IQ Battery 10T must be installed at least 3 ft from the ceiling.

What is the minimum clearance for a battery rack?

For battery racks, there shall be a minimum clearance of 25 mm (1 in.) between a cell container and any wall or structure on the side not requiring access for maintenance. Battery stands shall be permitted to contact adjacent walls or structures, provided that the battery shelf has a free air space for not less than 90 percent of its length.

What are the requirements for a battery installation?

1. Space Planning and Layout 900mm min Battery Room Layout 1200mm Primary Access End Access 1000mm Battery Racks Industrial battery installations require adequate spacing for maintenance, ventilation, and safety. The layout should accommodate: 2. Structural Requirements

What are the requirements for a battery location?

Battery locations shall conform to 480.9 (A), (B), and (C). (A) Ventilation. Provisions appropriate to the battery technology shall be made for sufficient diffusion and ventilation of gases from the battery, if present, to prevent the accumulation of an explosive mixture. (B) Live Parts. Guarding of live parts shall comply with 110.27.

Guess what you want to know

-

Can new energy battery cabinets withstand high temperatures

Can new energy battery cabinets withstand high temperatures

-

Palau has the largest number of photovoltaic communication battery cabinets

Palau has the largest number of photovoltaic communication battery cabinets

-

Italian authorized manufacturer of outdoor communication battery cabinets

Italian authorized manufacturer of outdoor communication battery cabinets

-

What types of liquid-cooled energy storage battery cabinets are included

What types of liquid-cooled energy storage battery cabinets are included

-

Various new energy battery cabinets

Various new energy battery cabinets

-

Which manufacturer should I look for for Seychelles outdoor communication battery cabinets

Which manufacturer should I look for for Seychelles outdoor communication battery cabinets

-

What are the specifications and sizes of battery cabinets for base stations

What are the specifications and sizes of battery cabinets for base stations

-

Outdoor photovoltaic communication battery cabinets

Outdoor photovoltaic communication battery cabinets

-

Reasonably priced battery cabinets in South Africa

Reasonably priced battery cabinets in South Africa

-

Battery energy storage cabinets built in Algeria

Battery energy storage cabinets built in Algeria

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.