Battery Cell VS Battery Module VS Battery Pack

Battery cells come in cylindrical, prismatic, and pouch designs. Cylindrical Cells: Advantages: Robust, consistent performance, high energy density. Disadvantages: Lower specific energy

Get a quote

How many cells does the energy storage battery have?

There are several influential factors that dictate the number of cells employed in energy storage batteries, including energy density, desired output, safety factors, and

Get a quote

Electric Vehicle Battery Cells Explained

EV batteries are composed of cells, and there are many types of cells. In this article, we will break them down in categories and go over the

Get a quote

The Primary Components of an Energy Storage System

For a solar and energy storage system, there is a choice between connecting the battery directly on the same DC bus where the PV lands (DC

Get a quote

Battery Cell VS Battery Module VS Battery Pack

Battery cells come in cylindrical, prismatic, and pouch designs. Cylindrical Cells: Advantages: Robust, consistent performance, high energy density.

Get a quote

A Guide to Battery Energy Storage System Components

Learn how to calculate the number of cells in lithium-ion energy storage batteries, with practical examples and expert insights into

Get a quote

How Many Battery Modules In A Tesla? Insights On EV Battery

Battery modules are composed of multiple battery cells. These cells convert chemical energy into electrical energy. The arrangement of cells within each module is crucial

Get a quote

What is a Battery Module?

Battery module is an intermediate energy storage unit between the battery cell and the battery pack. The battery module consists of a number of battery cells connected in series

Get a quote

How many cells does the energy storage battery have?

There are several influential factors that dictate the number of cells employed in energy storage batteries, including energy density, desired

Get a quote

Understanding Battery Energy Storage System (BESS)

44 number of cells connected in series in a module can also be increased to 48 and 52 series. The number of modules per rack can be 8 or 9, depending on the height of the

Get a quote

What Does a Battery Module Do? (Battery Module

A battery module is a device that provides power to an electronic device. It converts chemical energy into electrical energy. A battery module

Get a quote

How Many Cells Are in a Lithium-Ion Energy Storage Battery?

Learn how to calculate the number of cells in lithium-ion energy storage batteries, with practical examples and expert insights into configurations and applications.

Get a quote

Understanding Battery Modules: A Simple Guide —

The cells are the heart of any module, providing the primary energy storage. These cells can vary in type, such as lithium-ion or nickel

Get a quote

Battery Cell Module Pack: Everything You Need to Know

While the terms "battery cell," "battery module," and "battery pack" are often used interchangeably, the battery cell module pack refers to different stages of the battery''s

Get a quote

Understanding battery energy storage system (BESS)

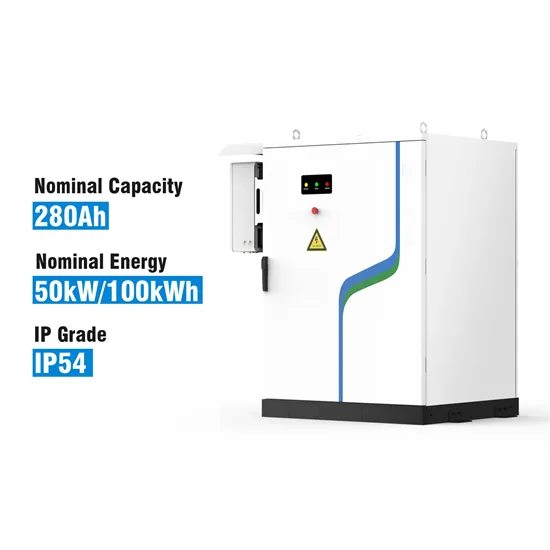

For the last few years, 280Ah LFP prismatic cell has been the trending cell used in containerised BESS (Battery Energy Storage System).

Get a quote

Battery Cells vs. Modules vs. Packs: How to Tell the Difference

Learn the differences between battery cells, modules, and packs. See how each layer works, why BMS and thermal systems matter, and where these components fit in EVs and energy storage.

Get a quote

Sturcture of Battery: From Cell to Module and Pack

The configuration of these cells within the module is designed to match the needs of the application, whether it is for higher voltage (like in

Get a quote

What Is A Lithium-Ion Battery Cell, Module, and Pack

The primary distinction between a battery module and a battery pack lies in their scale and functionality. A battery module is a smaller unit that

Get a quote

Power Battery Basics: Cells, Modules & Packs Explained

In this arrangement, 12 cells form a module, and eight modules combine to create the battery pack. The table below summarizes the key

Get a quote

A Guide to Battery Energy Storage System Components

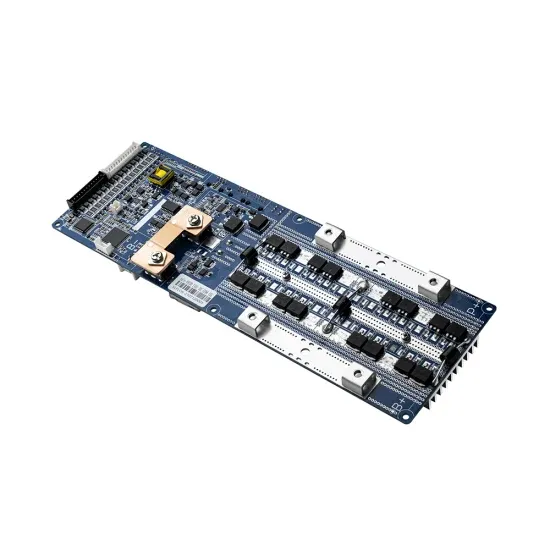

The battery comprises a fixed number of lithium cells wired in series and parallel within a frame to create a module. The modules are then stacked and combined to form a battery rack. Battery

Get a quote

EV Battery Module VS ESS Battery Module

The ESS battery module (Energy Storage System Battery Module) is part of a stationary energy storage system, consisting of multiple lithium-ion battery cells connected in

Get a quote

Battery Cell Module Pack: Everything You Need to Know

Battery cells are the basic electrochemical units. Modules are made up of multiple cells that work together to improve capacity and voltage.

Get a quote

Battery Cell Module Pack: Everything You Need to Know

Battery cells are the basic electrochemical units. Modules are made up of multiple cells that work together to improve capacity and voltage. Packs are full assemblies that include

Get a quote

Understanding Battery Energy Storage System

44 number of cells connected in series in a module can also be increased to 48 and 52 series. The number of modules per rack can be 8 or 9,

Get a quote

Hithium

HiTHIUM 314Ah ESS battery is tailored to meet the evolving needs of the power storage market by optimizing performance across multiple dimensions, including cell cost, system cost, and

Get a quote

Power Battery Basics: Cells, Modules & Packs Explained

In this arrangement, 12 cells form a module, and eight modules combine to create the battery pack. The table below summarizes the key distinctions between cells, battery

Get a quote

How Many Cells in an EV Battery Affect Performance and Structure?

In summary, the number of cells in an EV battery generally ranges from tens to thousands, influenced by the vehicle''s design, battery capacity, and technology

Get a quote

6 FAQs about [How many cells are there in an energy storage battery module ]

What are the critical components of a battery energy storage system?

In more detail, let’s look at the critical components of a battery energy storage system (BESS). The battery is a crucial component within the BESS; it stores the energy ready to be dispatched when needed. The battery comprises a fixed number of lithium cells wired in series and parallel within a frame to create a module.

What is the difference between battery cell and battery module?

Battery Cell: The basic unit of energy storage that converts chemical energy into electrical energy. It comes in various shapes (cylindrical, prismatic, or pouch) and contains an anode, cathode, separator, and electrolyte. Battery Module: A group of interconnected battery cells that increases voltage and capacity compared to individual cells.

What is the difference between battery module and battery pack?

Battery Module: A group of interconnected battery cells that increases voltage and capacity compared to individual cells. It includes wiring and connectors and may feature a basic battery management system (BMS) for monitoring. Battery Pack: A complete energy storage system containing one or more modules.

What are the different types of battery modules?

Battery module size and shape vary based on application and desired energy output. Common configurations include: Pouch-type modules: Flexible and lightweight, used in consumer electronics and electric vehicles. Prismatic modules: Rigid and stackable, commonly found in electric vehicles and energy storage systems.

What is a battery module?

It comes in various shapes (cylindrical, prismatic, or pouch) and contains an anode, cathode, separator, and electrolyte. Battery Module: A group of interconnected battery cells that increases voltage and capacity compared to individual cells. It includes wiring and connectors and may feature a basic battery management system (BMS) for monitoring.

What is the function of a battery cell?

It functions as the fundamental energy storage unit where electrochemical reactions take place to store and release energy. The characteristics of battery cells—such as their shape, size, and chemistry—significantly influence their performance, making them suitable for a variety of applications.

Guess what you want to know

-

How big is the energy storage battery module

How big is the energy storage battery module

-

How many applications does battery energy storage have

How many applications does battery energy storage have

-

How much does Israeli energy storage battery cost

How much does Israeli energy storage battery cost

-

How many kilowatt-hours of electricity can an outdoor energy storage battery store

How many kilowatt-hours of electricity can an outdoor energy storage battery store

-

How to use the liquid-cooled energy storage smart battery cabinet

How to use the liquid-cooled energy storage smart battery cabinet

-

How much does the Latvian communication base station energy storage battery system cost

How much does the Latvian communication base station energy storage battery system cost

-

How to use energy storage battery containers

How to use energy storage battery containers

-

How much does Kosovo s smart energy storage battery cost

How much does Kosovo s smart energy storage battery cost

-

How much does a 12v energy storage battery cost per ampere-hour

How much does a 12v energy storage battery cost per ampere-hour

-

How much current does the battery in an ordinary energy storage cabinet have

How much current does the battery in an ordinary energy storage cabinet have

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.