REDOX-FLOW BATTERY

Redox-flow batteries are electrochemical energy storage devices based on a liquid storage medium. Energy conversion is carried out in electrochemical cells similar to fuel cells. Most

Get a quote

Influence of temperature on performance of all vanadium redox flow

The main mass transfer processes of the ions in a vanadium redox flow battery and the temperature dependence of corresponding mass transfer properties of the ions were

Get a quote

Adjustment of Electrolyte Composition for All‐Vanadium Flow

Commercial electrolyte for vanadium flow batteries is modified by dilution with sulfuric and phosphoric acid so that series of electrolytes with total vanadium, total sulfate, and

Get a quote

Broad temperature adaptability of vanadium redox flow battery

This work systematically investigates the effects of the total vanadium concentration and sulfuric acid concentration on the temperature adaptability of VFBs for the first time as we

Get a quote

Improving the Performance of an All-Vanadium Redox

During the operation of an all-vanadium redox flow battery (VRFB), the electrolyte flow of vanadium is a crucial operating parameter,

Get a quote

A novel flow design to reduce pressure drop and enhance

The Vanadium Redox Flow Battery (VRFB) is one of the promising stationary electrochemical storage systems in which flow field geometry is essential to ensure uniform

Get a quote

Comparative analysis of single-acid and mixed-acid systems as

A comparison study was conducted for various supporting electrolytes of sulfuric acid (H 2 SO 4), hydrochloric acid (HCl), and mixed acids (H 2 SO 4 + HCl) in a vanadium

Get a quote

Accelerated design of vanadium redox flow battery

Stabilizing multiple vanadium oxidation states in aqueous solution is a primary challenge in designing reliable large-scale vanadium redox flow

Get a quote

State-of-art of Flow Batteries: A Brief Overview

In this flow battery system Vanadium electrolytes, 1.6-1.7 M vanadium sulfate dissolved in 2M Sulfuric acid, are used as both catholyte and anolyte. Among

Get a quote

Accelerated design of vanadium redox flow battery electrolytes through

Summary Operational stability of electrolytes is a persistent impediment in building redox flow battery technology. Stabilizing multiple vanadium oxidation states in aqueous

Get a quote

State-of-art of Flow Batteries: A Brief Overview

In this flow battery system Vanadium electrolytes, 1.6-1.7 M vanadium sulfate dissolved in 2M Sulfuric acid, are used as both catholyte and anolyte. Among the four available oxidation

Get a quote

Towards an all-vanadium redox-flow battery electrolyte

The electrochemistry of the V (IV)/V (III) redox couple influences the initial pre-charging of the electrolyte in vanadium redox-flow batteries to produce a catholyte and anolyte

Get a quote

Research progress of vanadium battery with mixed acid system:

Recently, vanadium redox flow battery (VRFB) has attracted extensive attention as a promising form of large-scale energy storage. However, its application is limited by issues

Get a quote

Adjustment of Electrolyte Composition for

Commercial electrolyte for vanadium flow batteries is modified by dilution with sulfuric and phosphoric acid so that series of electrolytes with

Get a quote

Accelerated design of vanadium redox flow battery electrolytes

Stabilizing multiple vanadium oxidation states in aqueous solution is a primary challenge in designing reliable large-scale vanadium redox flow batteries (VRBs).

Get a quote

Investigating the Effects of Operation Variables on All-Vanadium

In this work, an advanced 2D steady-state isothermal model of a unit cell all-vanadium redox flow battery has been presented. The model is based on recent state-of-art

Get a quote

Vanadium Redox Flow Battery

Each side of the cell is fed with an electrolyte containing sulfuric acid and a vanadium redox couple (see below), flowing through the porous electrodes. The liquid enters the cell from

Get a quote

Revealing sulfuric acid concentration impact on comprehensive

H 2 SO 4 concentration has an important influence on the performance of vanadium electrolytes and flow batteries. However, the comprehensive research is still

Get a quote

Vanadium redox flow batteries: A comprehensive review

A key advantage to redox flow batteries is the independence of energy capacity and power generation. The capacity of the battery is related to the amount of stored electrolyte in

Get a quote

Fact Sheet: Vanadium Redox Flow Batteries (October 2012)

Sulfuric acid solutions, the electrolyte used in current VRBs, can only hold a certain number of vanadium ions before they become oversaturated, and they only allow the battery to work

Get a quote

Improving the Performance of an All-Vanadium Redox Flow Battery

During the operation of an all-vanadium redox flow battery (VRFB), the electrolyte flow of vanadium is a crucial operating parameter, affecting both the system performance and

Get a quote

Investigation on the stability of electrolyte in vanadium flow

The effects of impurity, temperature, concentration of vanadium and sulphuric acid on the stability of electrolyte in vanadium redox flow batteries are studied. It is found that the

Get a quote

Recent Advances and Perspectives of Impurity Ions

The vanadium redox flow battery (VRFB) is an efficient electrochemical energy storage system, characterized by its energy efficiency,

Get a quote

Proton Conducting Organic-Inorganic Composite

Herein, we report surface-modified thermally crosslinked polyvinyl alcohol-silica (PVA-SiO2) membranes for the vanadium redox flow battery

Get a quote

Improved broad temperature adaptability and energy density of vanadium

The cell performance of vanadium redox flow battery with optimized electrolyte compositions indicates that the sulfate-chloride mixed acid electrolyte can operate at a wider

Get a quote

Electrolyte engineering for efficient and stable vanadium redox flow

The vanadium redox flow battery (VRFB), regarded as one of the most promising large-scale energy storage systems, exhibits substantial potential in th

Get a quote

Investigating the Effects of Operation Variables on All-Vanadium Redox

In this work, an advanced 2D steady-state isothermal model of a unit cell all-vanadium redox flow battery has been presented. The model is based on recent state-of-art

Get a quote

Bismuth concentration influenced competition between

The current obstacles for all-vanadium redox flow batteries (VRFBs) include the sluggish reaction kinetics of electrode materials and the overlapping potential range of the

Get a quote

Guess what you want to know

-

10kw all-vanadium redox flow battery

10kw all-vanadium redox flow battery

-

All-vanadium redox flow battery market share

All-vanadium redox flow battery market share

-

All-vanadium redox flow battery installation

All-vanadium redox flow battery installation

-

Kiribati all-vanadium redox flow battery manufacturer

Kiribati all-vanadium redox flow battery manufacturer

-

Equatorial Guinea Huijue all-vanadium redox flow battery

Equatorial Guinea Huijue all-vanadium redox flow battery

-

Yaounde s new all-vanadium redox flow battery

Yaounde s new all-vanadium redox flow battery

-

All-vanadium redox flow battery energy storage container

All-vanadium redox flow battery energy storage container

-

Benin all-vanadium redox flow battery

Benin all-vanadium redox flow battery

-

All-vanadium redox flow battery specific capacity

All-vanadium redox flow battery specific capacity

-

Organic Redox Flow Battery

Organic Redox Flow Battery

Industrial & Commercial Energy Storage Market Growth

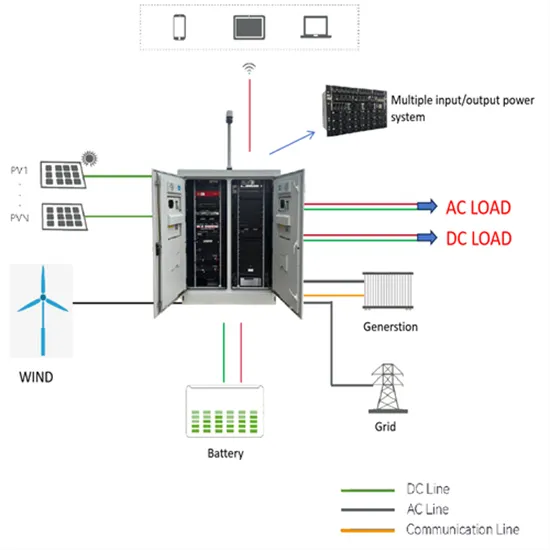

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.