Getting to Know the Layers on Solar Panels and Their Functions

The back layer of the solar panel that serves to protect the photovoltaic cells from moisture and environmental impacts. This layer also helps maintain the structural integrity of

Get a quote

NOVA | Saved By the Sun | Inside a Solar Cell | PBS

Solar panels capture sunlight and convert it to electricity using photovoltaic (PV) cells like the one illustrated above. Such cells, which can power everything

Get a quote

What Are Solar Panels Made Of And How Do They

This article will delve into the main components of solar panels, from the core photovoltaic cells to critical elements such as encapsulation materials, frames,

Get a quote

How Many Layers of Photovoltaic Panels Can You Actually

Let''s start with the solar industry''s worst-kept secret – 90% of rooftop photovoltaic panel installations use just one layer. Why? Imagine trying to wear three winter coats in July.

Get a quote

Anatomy of a Solar Panel: Understanding Its Structure

Explore the essential elements of a solar panel structure and how they harness the sun''s energy efficiently for India''s renewable future.

Get a quote

How many layers does a photovoltaic panel consist of

We explain how silicon crystalline solar cells are manufactured from silica sand and assembled to create a common solar panel made up of 6 main components - Silicon PV cells, toughened

Get a quote

The Anatomy of A Solar Panel | edp

As the name suggests, they are significantly thinner (approximately 350 times) compared to other solar panel types. Made with a variety of materials, they are produced by

Get a quote

What are solar panels made of and how are they

Answering that question means understanding how solar energy works, how solar panels are manufactured, and what the parts of a solar panel

Get a quote

Components That Make Up Solar Panels

Stanford researchers estimate that there are almost 1.5 million solar panels in the U.S. These solar panels are found in solar farms, on top of businesses'' roofs, and at people''s

Get a quote

The Anatomy of a Solar Cell: Constructing PV Panels

The heart of a PV cell lies in its semiconductor layers, typically made of silicon. When sunlight strikes these layers, the photons energize the

Get a quote

Flexible Solar Panels: Everything You Need To Know

Solar panel technology is rapidly advancing every year, and new developments like flexible solar panels are constantly evolving. Compared to conventional solar panels, flexible

Get a quote

How many layers of solar energy are installed? | NenPower

Solar panels, the most recognizable aspect of solar energy systems, consist of layers of photovoltaic (PV) cells. These cells are composed of semiconductor materials that

Get a quote

Solar Panel Construction

We explain how silicon crystalline solar cells are manufactured from silica sand and assembled to create a common solar panel made up of 6 main components - Silicon PV cells,

Get a quote

Exploring the Layers of a Solar Panel Structure

Uncover the essential layers that constitute a solar panel. Understand the composition and function of each layer in this insightful guide.

Get a quote

How many layers does a solar photovoltaic panel have

To understand how solar panels generate electricity, let''''s take a closer look at the photovoltaic cells (PV cells) in the solar panel. The PV cells are made up of two layers of silicon, one

Get a quote

What Are Solar Panels Made Of?

Discover the essential components of solar panels, including photovoltaic cells, glass, and frames. Learn how Rayzon Solar manufactures high-quality solar

Get a quote

Thin-Film Solar Panels: An In-Depth Guide | Types,

Overview: What are thin-film solar panels? Thin-film solar panels use a 2 nd generation technology varying from the crystalline silicon (c-Si)

Get a quote

Different Types Of Solar Panels In India: Cost,

Explore 10 different types of solar panels in India, ranging from first-generation monocrystalline panels to the advanced types of solar panels for

Get a quote

Photovoltaic Basics (Part 1): Know Your PV Panels for

To harness solar power effectively, one must understand photovoltaic technologies and system components. This two-part article

Get a quote

The Anatomy of a Solar Cell: Constructing PV Panels Layer by Layer

The heart of a PV cell lies in its semiconductor layers, typically made of silicon. When sunlight strikes these layers, the photons energize the electrons within the silicon

Get a quote

Solar Panel Manufacturing Process: Step-by-Step Guide

Complete solar panel manufacturing process – from raw materials to a fully functional solar panel. Learn how solar panels are made in a solar manufacturing plant,

Get a quote

Standard Solar Panel Sizes And Wattages (100W

This is the typical classification of solar panel sizes (based on the solar cell size). It''s a bit theoretical and quite useless for most calculations. The only useful

Get a quote

How Do Solar Panels Work? (Details Explained + Diagrams)

Solar panels work by converting the light radiation from the sun to Direct Current (DC) electricity through a reaction inside the silicon layers of the solar panel. The sun''s energy

Get a quote

Anatomy of a Solar Panel

To better understand their interiors, picture solar panel layers as a cross-section of a sandwich. The external layers or "bread slices" are made up of protective glass and polymer

Get a quote

6 FAQs about [Photovoltaic panels How many layers of solar panels]

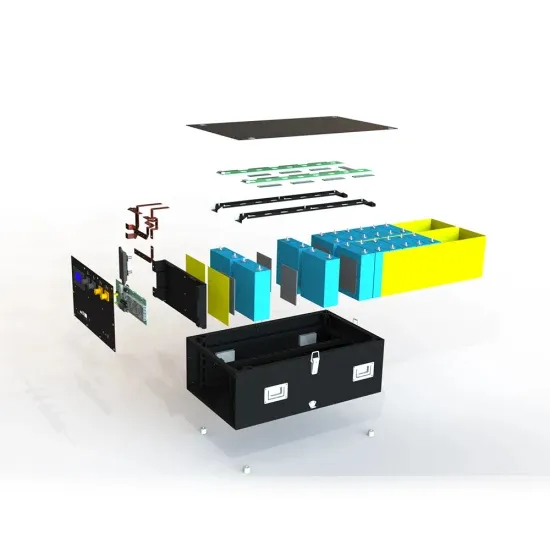

How many components are used in the construction of a solar panel?

The 6 main components used in the construction of a solar panel 1. Solar PV Cells Solar photovoltaic cells or PV cells convert sunlight directly into DC electrical energy. The solar panel's performance is determined by the cell type and characteristics of the silicon used, with the two main types being monocrystalline and polycrystalline silicon.

How many volts does a solar panel generate?

Most residential solar panels contain 60 full-size monocrystalline cells or 120 half-size cells linked together via busbars in series to generate a voltage between 30-40 volts, depending on the type of cell used.

What are the different types of solar panels?

The 6 main types of solar panels which use different types and size solar cells 2. Glass The front glass sheet protects the PV cells from the weather and impact from hail or airborne debris. The glass is typically high strength tempered glass which is 3.0 to 4.0mm thick and is designed resist mechanical loads and extreme temperature changes.

How are solar panels made?

This process involves melting the polycrystalline silicon under high pressure and temperature to slowly grow a large monocrystalline crystal known as an ingot. The thin base wafer is coated with an ultra-thin layer of either P-type or N-type silicon to form the PN-junction.

How do you choose a substrate material for a PV cell?

The choice of substrate material depends on the desired performance, cost, and application of the PV cell. The heart of a PV cell lies in its semiconductor layers, typically made of silicon. When sunlight strikes these layers, the photons energize the electrons within the silicon atoms, causing them to break free from their orbits.

What is a photovoltaic cell substrate?

Join us on this fascinating journey as we unveil the groundbreaking advancements in PV cell construction that are revolutionizing the renewable energy landscape and paving the way for a cleaner, greener future. The substrate is the foundation layer upon which the photovoltaic cell is built.

Guess what you want to know

-

How many layers of solar panels are there in a photovoltaic panel

How many layers of solar panels are there in a photovoltaic panel

-

How many solar panels are needed for a photovoltaic panel

How many solar panels are needed for a photovoltaic panel

-

How much heat can photovoltaic curtain wall solar panels withstand

How much heat can photovoltaic curtain wall solar panels withstand

-

How many volts are solar panels and photovoltaic panels

How many volts are solar panels and photovoltaic panels

-

How big is the area of 900w solar photovoltaic panels

How big is the area of 900w solar photovoltaic panels

-

How many watts are solar photovoltaic panels

How many watts are solar photovoltaic panels

-

Annual photovoltaic power generation of light-transmitting solar panels

Annual photovoltaic power generation of light-transmitting solar panels

-

Photovoltaic solar panels in South Ossetia

Photovoltaic solar panels in South Ossetia

-

Commercial solar panels photovoltaic power generation

Commercial solar panels photovoltaic power generation

-

East Asia factory photovoltaic solar panels

East Asia factory photovoltaic solar panels

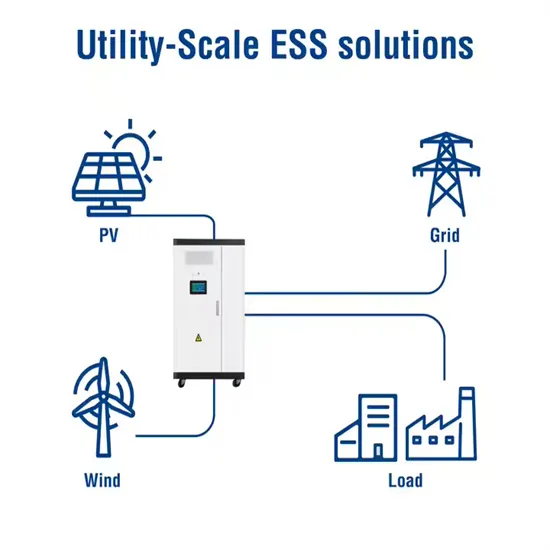

Industrial & Commercial Energy Storage Market Growth

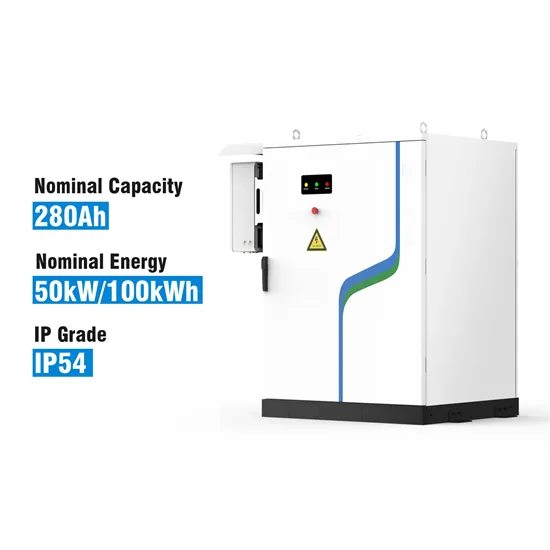

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.