PV and CEC text.doc

According to Rule 50-018, removal of a photovoltaic module or panel shall not interrupt the bonding conductor to other photovoltaic modules. This Rule requires that modules not be

Get a quote

Flexible Solar Panels: Complete Buying Guide, Pros

Explore the complete guide to flexible solar panels including pros, cons, applications, and expert installation tips. Ideal for RVs, boats, and off

Get a quote

Installation Guide for Flexible Photovoltaic Panels

In the pursuit of sustainable energy, flexible photovoltaic panels are gradually becoming the choice of many people. It not only has high-efficiency energy conversion

Get a quote

Code Requirement for Solar Photovoltaic (PV) Systems

PART I: BUILDING AND RESIDENTIAL CODE REQUIREMENTS Definitions: 1.1 Solar Photovoltaic (PV) System. The total components and subsystems that, in combination, convert

Get a quote

Flexible solar panel installation guide

Leave a slight gap between the flexible solar PV panels so that a cover strip (for example an anodised aluminium door threshold strip) can be installed and the roof panels stitched back

Get a quote

How to Mount Flexible Solar Panels: A

Mounting flexible solar panels involves applying an adhesive to the back of the panel and pressing it onto the desired surface, usually a roof or

Get a quote

Solar Conduits & Roof Penetrations Explained | Solar ME

Determining the best route for the conduit and properly sealing the roof penetrations are crucial steps in your solar panel installation process. You''ll

Get a quote

ETFE Thickness in Flexible Solar Panels: Which

Leading ETFE solar panel manufacturer explains thickness options (25-150μm) and their impact on performance, flexibility, and lifespan. Quality

Get a quote

64-4-* Wiring methods for solar photovoltaic systems

As per Rule 64-210 4) requirements for wiring support, acceptable supporting means are considered to be straps or other devices located within 300 mm of every box or fitting and at

Get a quote

Flexible Solar Panels: Complete Buying Guide, Pros and Cons

Explore the complete guide to flexible solar panels including pros, cons, applications, and expert installation tips. Ideal for RVs, boats, and off-grid systems

Get a quote

Flexible Solar Panels: Complete 2025 Guide & Best

Unlike their rigid counterparts, flexible solar panels can bend up to 360 degrees in some cases, weigh significantly less, and install with minimal

Get a quote

What Are the Grounding Requirements for Solar Panels?

When it comes to grounding requirements for solar panels, you must meet the stringent guidelines that are central to your project. Failure to

Get a quote

Advances in flexible perovskite solar cells: A

This distinctive design enables the creation of thin, flexible, and even transparent solar panels, enabling cutting-edge designs and unmatched versatility in energy production.

Get a quote

Photovoltaic Module

General engineering principals include safety factors when calculating adhesive bond area to avoid stressing the adhesive at or near the point of failure. The appropriate safety factor is

Get a quote

Transformational Solar Array Final Report

Such a thermal environment will lead to silicone oil being created under solar intensity and desorbing from the solar panel with this silicone oil being collected on the cooler concentrator.

Get a quote

Solar Photovoltaic: SPECIFICATION, CHECKLIST AND GUIDE

Install and label a 4'' x 4'' plywood panel area for mounting an inverter and balance of system components. Install a 1" metal conduit for the DC wire run from the designated array location

Get a quote

Solar Photovoltaic: SPECIFICATION, CHECKLIST AND GUIDE

As per Rule 64-210 4) requirements for wiring support, acceptable supporting means are considered to be straps or other devices located within 300 mm of every box or fitting and at

Get a quote

Flexible Solar Panels: Complete 2025 Guide & Best Options

Unlike their rigid counterparts, flexible solar panels can bend up to 360 degrees in some cases, weigh significantly less, and install with minimal mounting hardware. This guide

Get a quote

Solar panel bonding | Avery Dennison | Tapes

The Avery Dennison adhesive tape solutions provide solar panel manufacturers with advanced bonding advantages that outperform traditional methods and support the drive for greater

Get a quote

What is the process of grounding and bonding a solar PV array?

Using approved mechanical connectors and bonding washers are two popular bonding and grounding methods. Mechanical connectors can be mounted to a module or

Get a quote

How to Mount Flexible Solar Panels: A Comprehensive Guide for

Mounting flexible solar panels involves applying an adhesive to the back of the panel and pressing it onto the desired surface, usually a roof or deck of an RV, boat or van. It''s

Get a quote

PV framing and bonding technical manual

This manual is intended to provide guidance on sealant choice and proper application procedures for DuPontTM FortasunTM, formerly Dow Corning® brand, sealants for photovoltaic (PV)

Get a quote

What is the process of grounding and bonding a solar

Using approved mechanical connectors and bonding washers are two popular bonding and grounding methods. Mechanical connectors can be

Get a quote

NEC Requirements for Solar — Part 1 | EC&M

Article 690 covers solar installations, except large-scale ones (those are covered in Article 691) [Sec. 690.1], as shown in Fig. 1. There are

Get a quote

Bonding Fasteners for Solar Panel Mounting: The Definitive

Bonding fasteners for solar panel mounting represent a significant advancement in photovoltaic installation technology, offering superior performance characteristics that address

Get a quote

Solar PV Bonding | Flexible and Traditional | Scott Bader

For bonding lightweight flexible solar panels to roof structures, Scott Bader''s Crestabond M7 series and M1 series are recommended. Crestabond structural adhesives achieve a high

Get a quote

6 FAQs about [Flexible photovoltaic panel bonding area requirements]

How do you Mount flexible solar panels?

How to Mount Flexible Solar Panels: A Comprehensive Guide for DIY Enthusiasts - Solar Panel Installation, Mounting, Settings, and Repair. Mounting flexible solar panels involves applying an adhesive to the back of the panel and pressing it onto the desired surface, usually a roof or deck of an RV, boat or van.

How do you wire a flexible solar panel?

Press the panel down firmly, ensuring a solid bond between the panel and the surface. The good news is that flexible solar panels use the same wiring methods as any other solar panel. Choose between a series or parallel connection based on your individual power needs. Once connected, route your cables to the solar controller.

What are flexible solar panels?

Flexible solar panels are photovoltaic modules designed with bendable materials that allow them to conform to curved surfaces while maintaining their ability to generate electricity from sunlight.

Can flexible solar panels be installed on a fiberglass roof?

Flexible panels can be installed directly onto fiberglass or aluminum roofs using adhesive backing or minimal fasteners. For those considering a complete home solar solution, our residential solar panels offer similar efficiency benefits for permanent installations. Typical installations:

Are flexible solar panels better than rigid solar panels?

Traditional rigid solar panels have their place, but in some scenarios, flexible solar panels are distinctly advantageous. Imagine you’re decking out your RV or remodeling your boat – you’d prefer the smooth contour of flexible solar panels over the boxy rigidity of traditional panels.

What is the minimum array area requirement for a solar PV inverter?

Although the RERH specification does not set a minimum array area requirement, builders should minimally specify an area of 50 square feet in order to operate the smallest grid-tied solar PV inverters on the market.

Guess what you want to know

-

Flexible 24v solar panel photovoltaic

Flexible 24v solar panel photovoltaic

-

300w flexible photovoltaic panel size

300w flexible photovoltaic panel size

-

Flexible photovoltaic panel container installation

Flexible photovoltaic panel container installation

-

Djibouti flexible photovoltaic panel manufacturer

Djibouti flexible photovoltaic panel manufacturer

-

How much does a 10KW flexible photovoltaic panel cost

How much does a 10KW flexible photovoltaic panel cost

-

Flexible photovoltaic panel reliability

Flexible photovoltaic panel reliability

-

Flexible photovoltaic panel width 60 cm

Flexible photovoltaic panel width 60 cm

-

Swedish photovoltaic panel wholesale

Swedish photovoltaic panel wholesale

-

800w photovoltaic panel specifications

800w photovoltaic panel specifications

-

Photovoltaic panel power classification

Photovoltaic panel power classification

Industrial & Commercial Energy Storage Market Growth

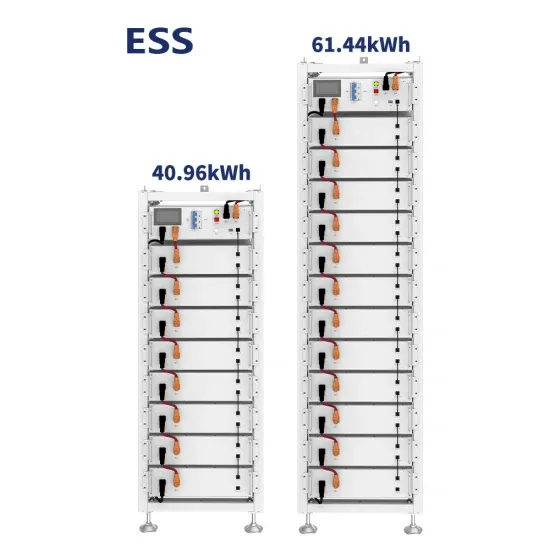

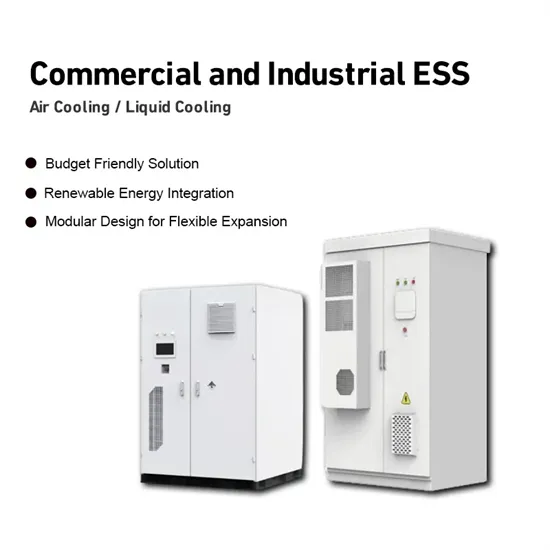

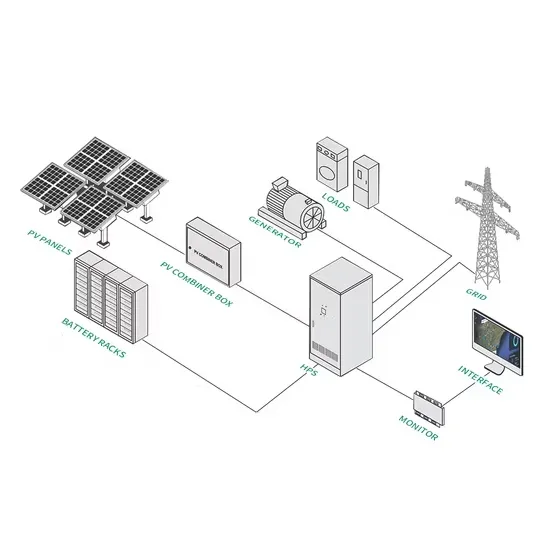

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

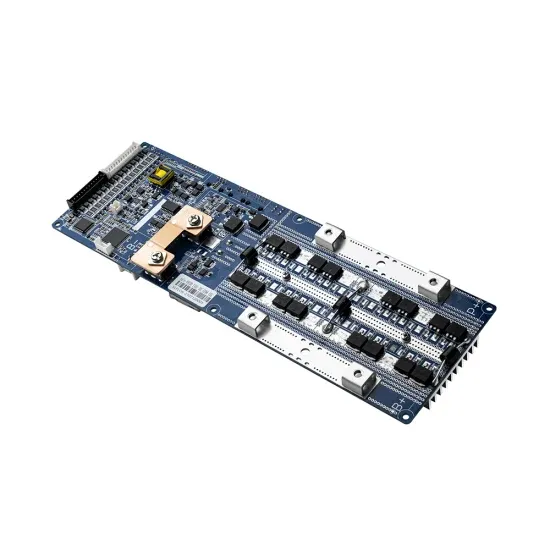

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.