Cost per kWh and the percentage cost breakdown for

Download scientific diagram | Cost per kWh and the percentage cost breakdown for Lead Acid battery-based energy storage. (Source: Own depiction) from

Get a quote

Levelized Costs of New Generation Resources in the Annual

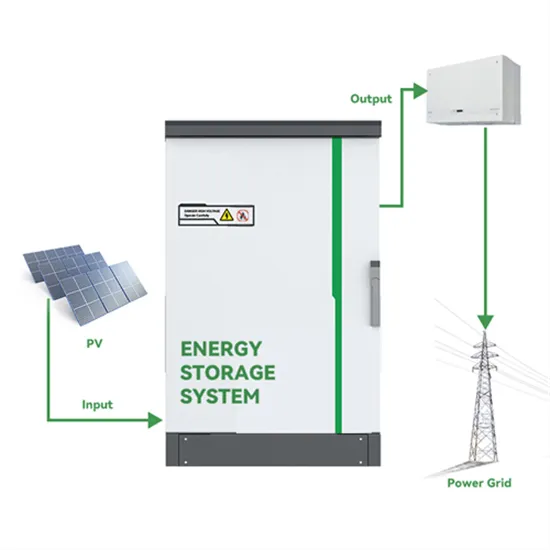

A solar PV-battery (PV-battery) hybrid system is a single-axis PV system coupled with a four-hour battery storage system. Costs are expressed in terms of net AC (alternating current) power

Get a quote

The Rise of Batteries in Six Charts and Not Too Many

RMI forecasts that in 2030, top-tier density will be between 600 and 800 Wh/kg, costs will fall to $32–$54 per kWh, and battery sales will rise

Get a quote

Lead Acid vs LFP cost analysis | Cost Per KWH

In summary, the total cost of ownership per usable kWh is about 2.8 times cheaper for a lithium-based solution than for a lead acid solution. We note that

Get a quote

Energy Storage Cost and Performance Database

In support of this challenge, PNNL is applying its rich history of battery research and development to provide DOE and industry with a guide to current energy

Get a quote

2mwh lead-carbon battery energy storage cost

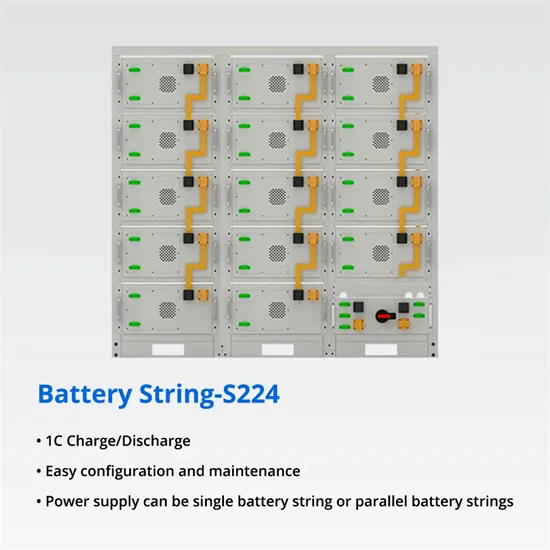

The heart of a 2MWh energy storage system is the battery modules. These modules are typically lithium-ion batteries, which offer high energy density, long cycle life, and fast charging

Get a quote

Energy Storage Cost and Performance Database

The U.S. Department of Energy''s (DOE) Energy Storage Grand Challenge is a comprehensive program that seeks to accelerate the development, commercialization, and utilization of next

Get a quote

Lithium vs. Lead Acid Batteries: A 10-Year Cost Breakdown for Energy

Discover why lithium batteries deliver 63% lower LCOE than lead acid in renewable energy systems, backed by NREL lifecycle data and UL-certified performance metrics。

Get a quote

Past, present, and future of lead–acid batteries | Science

When Gaston Planté invented the lead–acid battery more than 160 years ago, he could not have foreseen it spurring a multibillion-dollar

Get a quote

Grid-scale battery costs: $/kW or $/kWh?

Grid-scale battery costs can be measured in $/kW or $/kWh terms. Thinking in kW terms is more helpful for modelling grid resiliency. A good rule

Get a quote

A comparative life cycle assessment of lithium-ion and lead-acid

Lithium-ion battery technology is one of the innovations gaining interest in utility-scale energy storage. However, there is a lack of scientific studies about its environmental

Get a quote

What Does Green Energy Storage Cost in 2025?

In 2025, you''re looking at an average cost of about $152 per kilowatt-hour (kWh) for lithium-ion battery packs, which represents a 7% increase since 2021. Energy storage systems (ESS) for

Get a quote

How much does a storage battery cost per kilowatt-hour?

Meanwhile, lead-acid batteries generally offer a lower upfront cost, but they lack longevity and performance concerning energy density and cycle life. It''s also worth considering

Get a quote

How Much Does Commercial & Industrial Battery Energy Storage

While the cost per kWh can vary based on several factors, understanding these elements will help you make an informed decision. As technology advances and market

Get a quote

How Much Does Commercial & Industrial Battery Energy Storage Cost Per KWh?

While the cost per kWh can vary based on several factors, understanding these elements will help you make an informed decision. As technology advances and market

Get a quote

The Levelized Cost of Storage of Electrochemical Energy

Xue et al. (2016) framed a general life cycle cost model to holistically calculate various costs of consumer-side energy storage, the results of which showed the average annual cost of battery

Get a quote

Lithium-Ion Battery Pack Prices See Largest Drop

New York, December 10, 2024 – Battery prices saw their biggest annual drop since 2017. Lithium-ion battery pack prices dropped 20% from 2023 to a

Get a quote

Energy Storage Cost and Performance Database

In support of this challenge, PNNL is applying its rich history of battery research and development to provide DOE and industry with a guide to current energy storage costs and performance

Get a quote

(PDF) Lead-Carbon Batteries toward Future Energy

The lead acid battery has been a dominant device in large-scale energy storage systems since its invention in 1859. It has been the most

Get a quote

2022 Grid Energy Storage Technology Cost and Performance

The 2020 Cost and Performance Assessment provided installed costs for six energy storage technologies: lithium-ion (Li-ion) batteries, lead-acid batteries, vanadium redox flow batteries,

Get a quote

Lithium vs. Lead Acid Batteries: A 10-Year Cost

Discover why lithium batteries deliver 63% lower LCOE than lead acid in renewable energy systems, backed by NREL lifecycle data and UL-certified

Get a quote

2022 Grid Energy Storage Technology Cost and

The 2020 Cost and Performance Assessment provided installed costs for six energy storage technologies: lithium-ion (Li-ion) batteries, lead-acid batteries,

Get a quote

Lead Acid vs LFP cost analysis | Cost Per KWH Battery Storage

In summary, the total cost of ownership per usable kWh is about 2.8 times cheaper for a lithium-based solution than for a lead acid solution. We note that despite the higher facial cost of

Get a quote

Utility-Scale Battery Storage | Electricity | 2024 | ATB | NREL

The Storage Futures Study (Augustine and Blair, 2021) describes how a greater share of this cost reduction comes from the battery pack cost component with fewer cost reductions in BOS,

Get a quote

Battery Cost per kWh

From powering electric vehicles (EVs) to storing solar energy for homes and businesses, the cost per kilowatt-hour (kWh) of batteries is a defining factor in determining

Get a quote

Energy Storage Technology and Cost Characterization Report

This report defines and evaluates cost and performance parameters of six battery energy storage technologies (BESS) (lithium-ion batteries, lead-acid batteries, redox flow batteries, sodium

Get a quote

Utility-Scale Battery Storage | Electricity | 2022 | ATB | NREL

In this way, the cost projections capture the rapid projected decline in battery costs and account for component costs decreasing at different rates in the future. Figure 3 shows the resulting

Get a quote

Cost Projections for Utility-Scale Battery Storage: 2023 Update

In this work we describe the development of cost and performance projections for utility-scale lithium-ion battery systems, with a focus on 4-hour duration systems. The projections are

Get a quote

How much does a storage battery cost per kilowatt-hour?

Meanwhile, lead-acid batteries generally offer a lower upfront cost, but they lack longevity and performance concerning energy density and cycle

Get a quote

6 FAQs about [Lead-carbon battery energy storage cost per kilowatt-hour]

How much does a battery cost per kilowatt-hour?

Battery cost per kilowatt-hour (kWh) refers to the cost to manufacture or purchase one unit of energy storage. If a battery costs $120 per kWh and has a 10 kWh capacity, it would cost approximately $1,200. This metric helps compare pricing across different battery technologies and sizes.

How are battery energy storage costs forecasted?

Forecast procedures are described in the main body of this report. C&C or engineering, procurement, and construction (EPC) costs can be estimated using the footprint or total volume and weight of the battery energy storage system (BESS). For this report, volume was used as a proxy for these metrics.

How much does a lead-acid hybrid battery cost?

Lead-acid hybrid systems, such as the one produced by the manufacturer Ultrabattery, were not considered in this work because of their lower specific energy leading to higher unit energy costs for their 4-hour application. For vanadium redox flow batteries, with two exceptions the cost was in a tight range of $357–$584/kWh.

How much does a battery chemistry cost?

A fixed O&M cost of $10/kW-yr was used for all battery chemistries. Variable O&M includes all costs necessary to operate the storage system throughout the duration of its economic life and is normalized with respect to the annual discharge energy throughput.

Which battery energy storage technology has the lowest annualized value?

• On an annualized basis, Li-ion has the lowest total annualized $/kWh value of any of the battery energy storage technologies at $74/kWh, and ultracapacitors offer the lowest annualized $/kW value of the technologies included. An attempt was made to determine the cost breakdown among the various categories for PSH and CAES.

Are battery storage costs based on long-term planning models?

Battery storage costs have evolved rapidly over the past several years, necessitating an update to storage cost projections used in long-term planning models and other activities. This work documents the development of these projections, which are based on recent publications of storage costs.

Guess what you want to know

-

How much does one MW of battery energy storage cost per kilowatt-hour

How much does one MW of battery energy storage cost per kilowatt-hour

-

St Lucia lead-carbon battery energy storage system

St Lucia lead-carbon battery energy storage system

-

Energy storage cabinet electricity cost per kilowatt-hour

Energy storage cabinet electricity cost per kilowatt-hour

-

How much does a 380V 10kw mobile energy storage battery cost

How much does a 380V 10kw mobile energy storage battery cost

-

How much does the energy storage battery cabinet cost

How much does the energy storage battery cabinet cost

-

How much does energy storage battery cost in Costa Rica

How much does energy storage battery cost in Costa Rica

-

How much does the battery for the energy storage cabinet cost

How much does the battery for the energy storage cabinet cost

-

Cost price of Sino-European liquid-cooled energy storage battery cabinet

Cost price of Sino-European liquid-cooled energy storage battery cabinet

-

How much does a battery energy storage system cost

How much does a battery energy storage system cost

-

What energy storage battery has low cost

What energy storage battery has low cost

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.