A comparative overview of large-scale battery systems for

In this section, the characteristics of the various types of batteries used for large scale energy storage, such as the lead–acid, lithium-ion, nickel–cadmium, sodium–sulfur and

Get a quote

How do the energy densities of lithium-ion and nickel-cadmium

Nickel-cadmium batteries have a moderate energy density, usually between 45–80 Wh/kg. This makes them heavier and bulkier relative to the energy they store compared

Get a quote

How do the energy densities of lithium-ion and nickel-cadmium batteries

Nickel-cadmium batteries have a moderate energy density, usually between 45–80 Wh/kg. This makes them heavier and bulkier relative to the energy they store compared

Get a quote

Comprehensive review of energy storage systems technologies,

NiCd battery can be used for large energy storage for renewable energy systems. The efficiency of NieCd battery storage depends on the technology used during their

Get a quote

What kind of battery is used in the energy storage cabinet

Lastly, Nickel-cadmium batteries are durable in adverse conditions, although their use is less common due to environmental concerns related to cadmium. A thorough

Get a quote

Metals in Battery Energy Storage Systems: A Comprehensive

Nickel plays a crucial role in increasing the energy capacity of lithium-ion batteries, making it valuable for large-scale applications like grid stabilization and renewable energy

Get a quote

Can nickel-cadmium batteries store energy on a large scale

Secondary batteries, such as lead-acid, nickel-cadmium, and lithium-ion batteries can be deployed for energy storage, but require some re-engineering for grid applications.

Get a quote

Hubble Battery Tech Holds Power on Earth | NASA Spinoff

Although they are bigger and heavier than lithium-ion cells, the batteries provide more energy storage per square foot of floor space than alternatives, the company said. This

Get a quote

Nickel-based batteries for medium

Ni-Cd batteries offer excellent cycle life, good low-temperature performance, and exceptional tolerance of high discharge rates, combined with versatility in size, ranging from

Get a quote

Battery Hazards for Large Energy Storage Systems

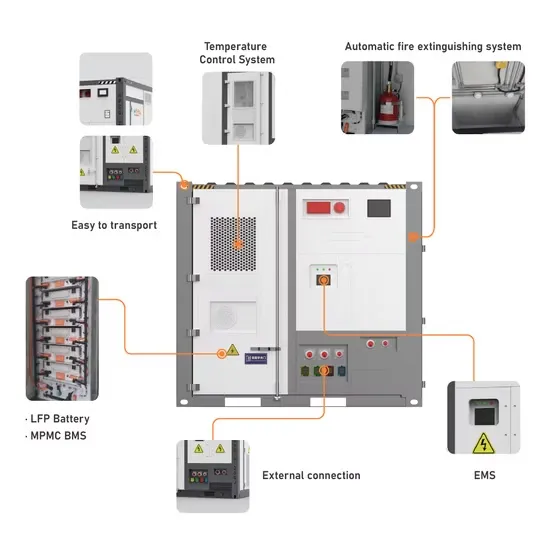

Figure 1 depicts the various components that go into building a battery energy storage system (BESS) that can be a stand-alone ESS or can

Get a quote

Different Types of Battery Energy Storage Systems (BESS)

These batteries offer high energy density and are primarily used for large-scale applications, such as grid storage and load balancing. Pros: High energy density, well-suited

Get a quote

Grid-Scale Energy Storage

Electricity Time-Shifting: Grid-scale energy storage can store cheaper electricity generated during off-peak hours and dispatch it to match higher demand during peak hours. Additionally, grid

Get a quote

nickel-cadmium battery large-scale energy storage

Nickel Cadmium Battery A comparative overview of large-scale battery systems for electricity storage Andreas Poullikkas, in Renewable and Sustainable Energy Reviews, 2013 2.3

Get a quote

Battery Energy Storage

3.1 Battery energy storage The battery energy storage is considered as the oldest and most mature storage system which stores electrical energy in the form of chemical energy [47, 48].

Get a quote

Ultimate Showdown: Comparing Different Types of Solar Energy

Nickel-cadmium batteries are particularly suited for heavy-duty applications like commercial aviation, utilities, and large-scale solar energy storage. Despite their efficiency and

Get a quote

What are the Different Types of Utility-scale Batteries?

Discover the different types of utility-scale batteries, including lithium-ion, lead-acid, flow, sodium-sulfur, nickel-cadmium, and solid-state batteries. Learn about their advantages,

Get a quote

Key Differences Between NiCd and NiMH Batteries

Compare nickel cadmium vs nickel metal hydride battery types to understand differences in energy density, lifespan, environmental impact, and application suitability.

Get a quote

Nicd battery tech: modern uses & understanding

While lithium-ion batteries dominate the portable electronics market, Nickel-Cadmium (NiCd) batteries retain a significant presence in specific niches. Their robust nature, high discharge

Get a quote

Battery Hazards for Large Energy Storage Systems

Figure 1 depicts the various components that go into building a battery energy storage system (BESS) that can be a stand-alone ESS or can also use harvested energy from

Get a quote

Vanadium Redox Flow Batteries for Large-Scale Energy Storage

After batteries like nickel-cadmium and lithium-ion batteries are being completely used up, several leaching techniques are applied for recycling, because of their toxicity,

Get a quote

Nickel-Cadmium Batteries: A Comprehensive Guide

Discover the benefits and limitations of Nickel-Cadmium batteries in energy storage, including their history, working principle, and uses.

Get a quote

Answering Frequently Asked Questions About NFPA 855

Some of the impactful requirements of NFPA 855 include: Large-scale fire testing shall be conducted on a representative energy storage system (ESS) in accordance with UL

Get a quote

Metals in Battery Energy Storage Systems: A

Nickel plays a crucial role in increasing the energy capacity of lithium-ion batteries, making it valuable for large-scale applications like grid

Get a quote

Lead batteries for utility energy storage: A review

Li-ion batteries have advantages in terms of energy density and specific energy but this is less important for static installations. The other technical features of Li-ion and other

Get a quote

6 FAQs about [Can nickel-cadmium batteries store energy on a large scale ]

What are the different types of batteries used for large scale energy storage?

In this section, the characteristics of the various types of batteries used for large scale energy storage, such as the lead–acid, lithium-ion, nickel–cadmium, sodium–sulfur and flow batteries, as well as their applications, are discussed. 2.1. Lead–acid batteries

What type of batteries can be used for energy storage?

Secondary batteries, such as lead–acid and lithium-ion batteries can be deployed for energy storage, but require some re-engineering for grid applications . Grid stabilization, or grid support, energy storage systems currently consist of large installations of lead–acid batteries as the standard technology .

How does a nickel cadmium battery work?

The operation of the nickel-cadmium battery is based upon the redox reaction between nickel oxide hydroxide and cadmium. The key active units in a fully charged cell include a positive nickel oxide hydroxide electrode, a negative cadmium electrode, a separator, and an alkaline electrolyte that is normally potassium hydroxide.

What metals are used in battery energy storage systems?

Battery energy storage systems (BESS) utilize a variety of metals, each contributing to different aspects of battery performance and efficiency. Key metals include lithium, nickel, cobalt, manganese, iron, lead, vanadium, copper, aluminum, and graphite. Lithium is fundamental in lithium-ion batteries, facilitating ion migration between electrodes.

What is a nickel based battery?

Introduction Nickel-based batteries include nickel-cadmium (commonly denoted by Ni-Cd), nickel-iron (Ni-Fe), nickel-zinc (Ni-Zn), nickel-hydrogen (Ni-H ), and nickel metal hydride (Ni-MH). All these batteries employ nickel oxide hydroxide (NiOOH) as the positive electrode, and thus are categorized as nickel-based batteries.

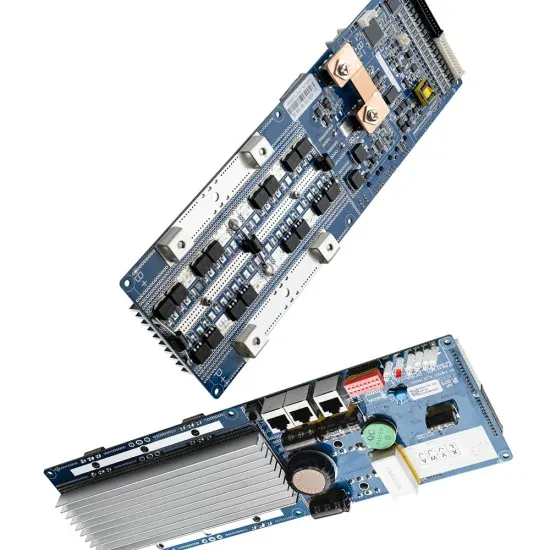

What components go into building a battery energy storage system?

Figure 1 depicts the various components that go into building a battery energy storage system (BESS) that can be a stand-alone ESS or can also use harvested energy from renewable energy sources for charging. The electrochemical cell is the fundamental component in creating a BESS.

Guess what you want to know

-

How to store energy with lead-acid batteries

How to store energy with lead-acid batteries

-

Large pool of energy storage batteries

Large pool of energy storage batteries

-

What batteries are used in large energy storage stations

What batteries are used in large energy storage stations

-

Multiple voltage energy storage batteries

Multiple voltage energy storage batteries

-

Which household has more energy storage batteries

Which household has more energy storage batteries

-

Introduction to Large Energy Storage Vehicles

Introduction to Large Energy Storage Vehicles

-

How much is the wholesale price of energy storage cabinet batteries in Chile

How much is the wholesale price of energy storage cabinet batteries in Chile

-

5 strings of 60V energy storage batteries

5 strings of 60V energy storage batteries

-

Main uses of energy storage batteries

Main uses of energy storage batteries

-

How much is the demand for energy storage batteries

How much is the demand for energy storage batteries

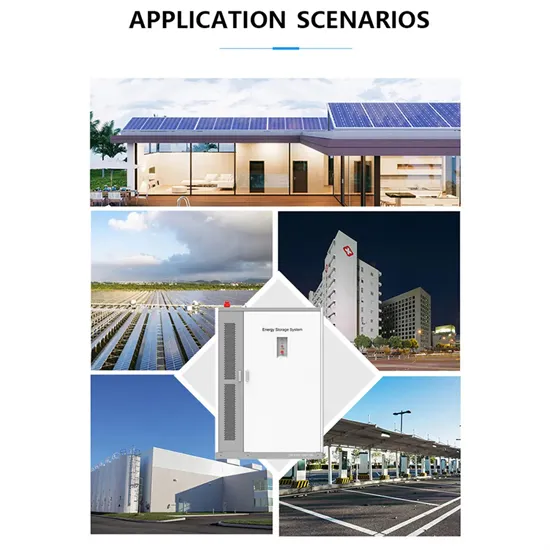

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.