CONSTRUCTION OF BASE STATIONS FOR GUYED

Construction: Undertake the construction of base stations, including the installation of necessary equipment (e.g., antennas, transmitters, power supply systems). Testing and Commissioning:

Get a quote

COMMUNICATION SITE BUILDING DESIGN AND

For example, a CO may contain a cellular or Personal Communications Services (PCS) switch and/or centralized base station controllers. Good design is even more critical for a CO

Get a quote

Concrete Foundations in Substations and Transmission

Concrete foundations support transmission towers and high-voltage substation equipment including transformers, circuit breakers, feeder lines, capacitor banks, switches, and

Get a quote

Process of Installing a Base Transceiver Station (BTS)

Installing a Base Transceiver Station (BTS) is a critical step in building mobile communication networks. Here''s a step-by-step guide to the

Get a quote

Guidelines on Technical Specifications for the Installation of

When non-standard foundations and anchors are to be used for construction, the soil parameters recommended by the geo-technical engineer should incorporate a minimum safety factor of

Get a quote

Process of Installing a Base Transceiver Station (BTS)

Installing a Base Transceiver Station (BTS) is a critical step in building mobile communication networks. Here''s a step-by-step guide to the process:

Get a quote

Foundations 101: Understanding the Excavation and

The process of creating a foundation involves excavation and formwork, which are critical steps in the construction journey. In this guide, we will delve into

Get a quote

Construction of telecommunication towers

The document provides a final presentation on improving quality and productivity in the construction of telecom towers. It identifies key issues with current

Get a quote

Communication tower foundation selection and design

According to the foundation design of two types of towers commonly used in the construction of communication base stations in Hebei

Get a quote

Microsoft PowerPoint

Base stations are often in enclosed spaces and experience wide temperature variations. These systems need to operate with high reliability for years Means some reconfigurable devices.

Get a quote

Communication Tower Foundation Design: 2025 Complete Guide

Every step of the process ensures a strong and enduring foundation- from smart sensor integration and soil analysis to structural integrity and advanced grounding systems.

Get a quote

Construction of Telecom Tower | PDF | Surveying

• The study is limited only to address the construction related issues. Design related issues are not in the scope of the study. • The study is limited to

Get a quote

Communication tower foundation selection and design

According to the foundation design of two types of towers commonly used in the construction of communication base stations in Hebei China Unicom in recent years, the

Get a quote

Inverter Transformer: Construction Fundamentals and Working Principle

A brief introduction to an inverter transformer. Construction of inverter transformer assembly with fundamental components. Explained with the working principle & common

Get a quote

5G Communication Base Stations Participating in Demand

With the rapid development of the construction and application of 5G communication networks in the power grid, more and more 5G base stations need to be built

Get a quote

Base Stations

Base stations form a key part of modern wireless communication networks because they offer some crucial advantages, such as wide coverage, continuous communications and

Get a quote

Validation request

[ Refresh the page to generate a new image. ] Note: If you get here while trying to submit a form, you may have to re-submit the form. Access to this domain may need the

Get a quote

05 inverter_station_foundation_0 | PDF | Power Inverter

• Mapping of foundation layout on the ground as per Approved/RFC (Release for Construction) drawing. • Temporary marking of layout with Lime powder or paint for all foundations of

Get a quote

What is the function of the Base Transceiver Station

The Base Transceiver Station (BTS) is a critical component of the cellular network architecture, particularly in the GSM (Global System for

Get a quote

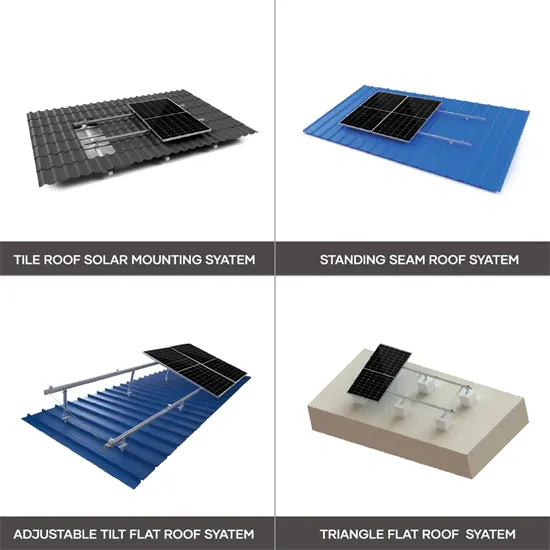

Drawings & Documents Required for Solar Projects

The document is a comprehensive list of drawings and documents related to a solar plant project, detailing various layouts, designs, and specifications for

Get a quote

Telecommunication Tower Reinforced Concrete Foundation

This case study focuses on the design of a telecom tower foundation using the engineering software program spMats. The tower under study is a 100 ft high and all members are hot-dip

Get a quote

Construction of Cell Site | SIX Construction

It''s essential to consult with experts and follow industry best practices when building a cell site tower. A cell site, also known as a cell tower or base station, is a structure that hosts the

Get a quote

6 FAQs about [Communication base station inverter foundation construction process]

What are the different types of concrete foundations in substations?

The primary types of concrete foundations in substations are pedestals and slabs. Figure 2-2 shows a typical design of pedestal commonly used in substations. Note the air gap between the metal plate and the concrete. In many cases, this gap is filled with grout to prevent moisture ingress.

What type of foundation is used in a substation?

Note that in most cases, the foundation and the cap, or pedestal, are the same structure, and the top portion of this structure can be accessed and visually inspected. The primary types of concrete foundations in substations are pedestals and slabs. Figure 2-2 shows a typical design of pedestal commonly used in substations.

Can EPRI develop a management guide for concrete foundations in substations?

EPRI may develop a similar set of management and field guides focused on concrete foundations in substations. EPRI has performed extensive work in the past on the design, maintenance, and inspection of concrete structures in relation to hydroelectric dams.

How do you build a cell site tower?

QUALITY. Building a cell site tower requires careful planning, precise engineering, and rigorous construction. Here’s a comprehensive guide on the methods to build a cell site tower: I. Planning and Design (Weeks 1-4) Site acquisition: Secure a suitable location for the tower.

How does a base station work?

It usually connects the device to other networks or devices through a dedicated high bandwidth wire of fiber optic connection. Base stations typically have a transceiver, capable of sending and receiving wireless signals; Otherwise if they only send the trailer it will be considered a transmitter or broadcast point only.

What type of structure is used for a telecom tower foundation?

So very stable structure types like lower lattice towers and towers built of reinforced concrete are used in most cases, although also guyed masts are used for taller application. This case study focuses on the design of a telecom tower foundation using the engineering software program spMats.

Guess what you want to know

-

The whole process of communication base station inverter foundation construction

The whole process of communication base station inverter foundation construction

-

Communication base station inverter grid-connected installation construction process

Communication base station inverter grid-connected installation construction process

-

Necessity analysis of communication base station inverter construction

Necessity analysis of communication base station inverter construction

-

Base station communication power supply construction process

Base station communication power supply construction process

-

Communication base station inverter construction site

Communication base station inverter construction site

-

Communication base station inverter grid connection and station startup process

Communication base station inverter grid connection and station startup process

-

Turkmenistan 5G communication base station inverter construction

Turkmenistan 5G communication base station inverter construction

-

Samoa Communication Base Station Inverter Construction Plan

Samoa Communication Base Station Inverter Construction Plan

-

Luxembourg communication base station energy storage system foundation construction

Luxembourg communication base station energy storage system foundation construction

-

City Communication Base Station Inverter Grid Connection Construction Plan

City Communication Base Station Inverter Grid Connection Construction Plan

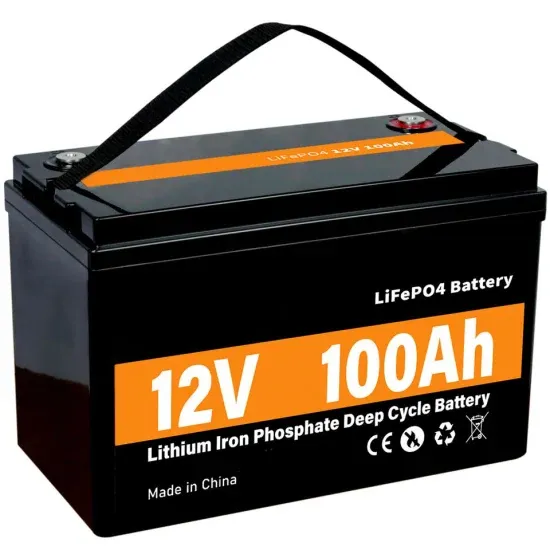

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.