Substation inverter control for AC electrified transportation

The advanced substation configuration, already proposed by the authors in previous publications, has been further improved with reference to compensator configuration, inverter control and

Get a quote

Protection System for a Collector Substation That

This paper describes the protection system developed for the collector substation of a large PV plant to protect buses, GSU transformers, feeders, and capacitor banks.

Get a quote

Substation inverter control for AC electrified transportation systems

The paper deals with AC substation inverter control for power quality improvement in high speed railways. The advanced substation configuration, already proposed by the authors in previous

Get a quote

Substation inverter control for AC electrified transportation systems

The advanced substation configuration, already proposed by the authors in previous publications, has been further improved with reference to compensator configuration, inverter control and

Get a quote

Inverter operating characteristics optimization for DC traction

Abstract—Compared with energy storage equipment based on supercapacitors, flywheels or lithium batteries, inverters have obvious advantages in installation space, cost, reliability and

Get a quote

Switching and Protection solutions for 800VAC Recombiners

Discover the ABB Switching & Protection solutions for protecting and securing AC Recombiners. Quickly configure Commercial & Industrial Photovoltaic (PV) plants with several string

Get a quote

Solid State Power Substation Technology Roadmap

Design and development of a flexible, standardized power electronic converter that can be applied across the full range of grid applications and configurations can enable the economy of scale

Get a quote

AC Substations and Earthing System Fundamentals

A route length of more than 7,000 km of overhead lines represent a part of the UK Electricity Transmission system, including about 700 km of underground cable

Get a quote

25 kV AC railway electrification

Railway electrification systems using alternating current (AC) at 25 kilovolts (kV) are used worldwide, especially for high-speed rail. It is usually supplied at the standard utility frequency

Get a quote

Inverter Upgraded for Substations

Delivers 1200 watts of clean, regulated AC power from batteries or other DC sources for reliable substation monitoring. Behlman Electronics Inc. has upgraded its INV

Get a quote

Major components of the HVDC converter station

The interconnection of HVDC can bring many benefits to the AC system. Single line diagram of one end of a HVDC bipole converter Figure 1

Get a quote

Solar Inverter Sub Station

1.Advanced Inverters: At the heart of the substation are high-efficiency inverters that handle the DC to AC conversion. Modern inverters feature advanced technologies such as maximum

Get a quote

60 MW grid tied solar power plant with 115 kV/34.5 kV substation

The inverter outputs three phase AC current to a step-up transformer. The step-up transformer outputs to a collector in the substation component, in which flows to the collector

Get a quote

Michigan Economic Development Corporation

High-Voltage, High-Frequency Devices for Solid State Power Substation and Grid Power Converters Allen R. Hefner Semiconductor Electronics Division National Institute of Standards

Get a quote

Solid State Power Substation Technology Roadmap

A solid state power substation (SSPS), defined as a substation or "grid node" with the strategic integration of high-voltage power electronic converters, can provide system benefits and

Get a quote

60 MW grid tied solar power plant with 115 kV/34.5 kV

The inverter outputs three phase AC current to a step-up transformer. The step-up transformer outputs to a collector in the substation

Get a quote

Microsoft Word

The solar plant will produce power which will be directed to the grid via a substation. The plant will contain the solar arrays and inverters. The substation contain all necessary components

Get a quote

Solar Transformers: Sizing, Inverters, and E-Shields

Learn all about transformer sizing and design requirements for solar applications—inverters, harmonics, DC bias, overload, bi-directionality,

Get a quote

DC railway system. The dc catenary is generated by the substation

The diagram of the dc railway system shows that the ac transmission line feeds the dc catenary voltage V CAT through the substation, which consists of a three-phase transformer and a 12

Get a quote

Inverter complete transformer substation

Complete transformer substation of inverter type for converting direct current of photovoltaic modules into alternating three-phase current 50 Hz 10 kV. The

Get a quote

AN INTRODUCTION TO INVERTER-BASED RESOURCES

Inverter-based resources are now found everywhere across the bulk power system (BPS) in North America and are the most significant driver of grid transformation today.

Get a quote

Solar Inverter Sub Station

As the demand for renewable energy grows, solar inverter substations are becoming increasingly sophisticated. They are not only crucial for maximizing the efficiency of solar power systems

Get a quote

Modelling, simulating and parameter designing for traction power system

The bidirectional converter device (BCD) can substitute the substation rectifier and the energy feedback system (EFS) by transforming energy between the AC side and DC side.

Get a quote

Introduction to HVDC Architecture and Solutions for Control

The converter station and protection systems are designed such a way that the ac protection of the converter and adjacent ac substation are not affected by the normal, transient and

Get a quote

6 FAQs about [Substation AC system inverter]

What is an inverter substation?

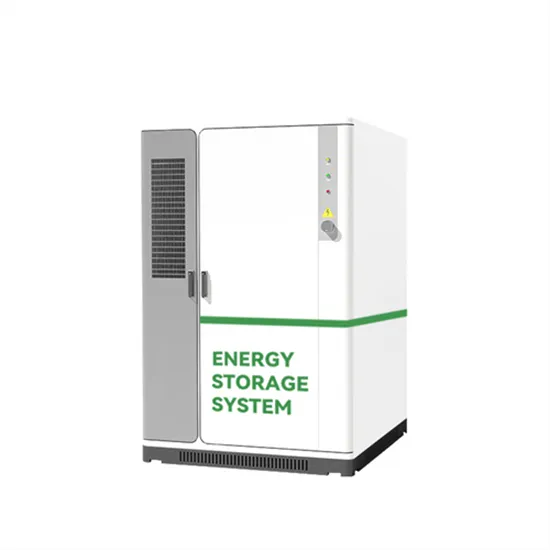

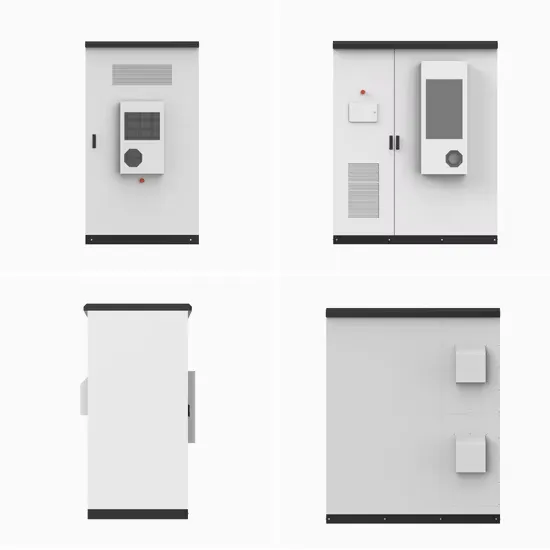

Inverter substation - this CSS is made with a concrete or or sheet metal base frame (per market requirements) per the latest IEC standard 62271-202 consists of DC/AC inverters, primary low voltage AC switchboard, step up distribution transformer (oil or dry type) and medium voltage gas insulated or air insulated secondary switchgear.

What is a solid state power substation (SSPs)?

Substations or “grid nodes” with the strategic integration of high-voltage power electronic converters, discussed from here on as solid state power substations (SSPS), can provide advanced capabilities and facilitate evolution of the electric power system.

How does a power electronic converter affect a substation?

For example, harmonics from power electronic converters can lead to unwanted resonances that can influence the operation and lifetimes of other substation equipment. EMI impacts, noise, and overall substation footprint are other facets that need to be considered.

What is a transformer substation?

Transformer substations, collector stations and inverter substation meeting the latest global IEC standards up to 24 kV. Solar and wind renewable energy is rapidly growing globally. Power is generated at low voltage DC levels and transformed up to medium voltages for network distribution.

How does an inverter work?

The inverter outputs three phase AC current to a step-up transformer. The step-up transformer outputs to a collector in the substation component, in which flows to the collector arrangement, feeder arrangement and key protection component. Finally, it is fed to the grid at 115 kV.

What is a power inverter?

“Inverters” is the general term for power electronic converters that change DC power to AC power. These power electronic systems are critical to the integration of variable renewable resources and battery energy storage because they enable the electricity generated or stored to be injected back into the grid.

Guess what you want to know

-

Charging pile DC to AC 220 inverter

Charging pile DC to AC 220 inverter

-

How to connect the AC side of the inverter to the grid

How to connect the AC side of the inverter to the grid

-

Barbados AC inverter manufacturer

Barbados AC inverter manufacturer

-

Smart upgraded AC 220 inverter

Smart upgraded AC 220 inverter

-

20v lithium battery inverter converts 220v into AC power

20v lithium battery inverter converts 220v into AC power

-

PV inverter direct AC

PV inverter direct AC

-

What are the functions of AC inverter

What are the functions of AC inverter

-

Can AC be connected to an inverter

Can AC be connected to an inverter

-

What does inverter AC mean

What does inverter AC mean

-

Is AC or DC inverter better

Is AC or DC inverter better

Industrial & Commercial Energy Storage Market Growth

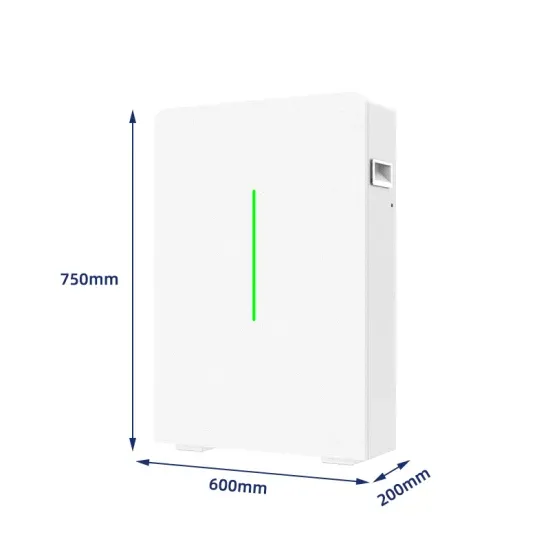

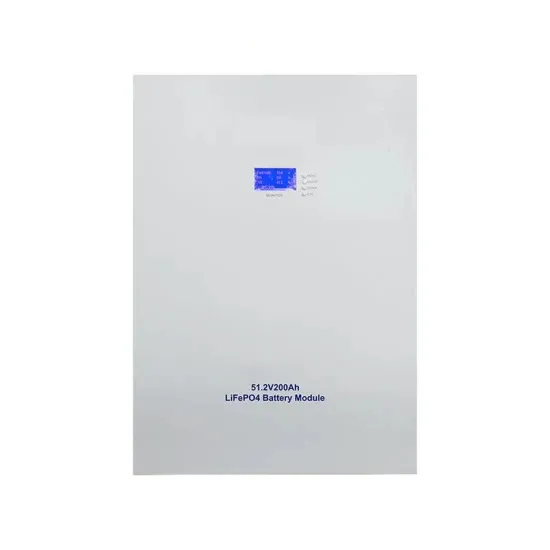

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.