How are solar photovoltaics produced? | NenPower

DOPING AND TREATMENT OF WAFERS After the silicon wafers are fabricated, they undergo a crucial process known as doping. Doping is the intentional introduction of

Get a quote

Solar Photovoltaic Manufacturing Basics

Power electronics for PV modules, including power optimizers and inverters, are assembled on electronic circuit boards. This hardware converts direct current (DC) electricity, which is what a

Get a quote

The global solar silicon wafer market is expected to grow with a

Trends, opportunities and forecast in solar silicon wafer market to 2027 by type (monocrystalline wafers and polycrystalline wafers), application (PV modules, inverters, solar

Get a quote

Silicon carbide photovoltaic cells

Si-rich-silicon carbide Photovoltaic Density functional theory ABSTRACT Silicon carbide has been used in a variety of applications including solar cells due to its high stability. The high bandgap

Get a quote

Wafers in photovoltaics

There are different types of wafers used in photovoltaics, with silicon wafers being the most commonly used. They can be further subdivided into monocrystalline and

Get a quote

Solar Wafers: Key to Efficient Solar Panels

Explore the role of solar wafers in efficient solar panels, their types, manufacturing process, and contribution to reducing carbon emissions in the supply chain.

Get a quote

What Is a Silicon Wafer for Solar Cells?

Silicon wafers are by far the most widely used semiconductors in solar panels and other photovoltaic modules. P-type (positive) and N-type (negative) wafers are manufactured and

Get a quote

Trends of Solar Silicon Wafer Size and Thickness for Different

This article explores the latest trends in silicon wafer size and thickness for different cell technologies, based on insights from recent industry reports and intelligence.

Get a quote

Solar Photovoltaic Manufacturing Basics

Power electronics for PV modules, including power optimizers and inverters, are assembled on electronic circuit boards. This hardware converts direct current

Get a quote

How Solar Silicon Wafers Are Made into Cells | NenPower

How Solar Silicon Wafers Are Made into Cells. The process of transforming solar silicon wafers into cells involves several meticulous steps, including wafer slicing, doping, and

Get a quote

Trends of Solar Silicon Wafer Size and Thickness for

This article explores the latest trends in silicon wafer size and thickness for different cell technologies, based on insights from recent industry

Get a quote

PVEducation

6.1. Silicon Wаfers & Substrates Refining Silicon Types Of Silicon Single Crystalline Silicon Czochralski Silicon Float Zone Silicon Multi Crystalline Silicon Wafer Slicing Other Wafering

Get a quote

Solar Photovoltaics Supply Chain Review Report

The supply chain for c-Si PV starts with the refining of high-purity polysilicon. Polysilicon is melted to grow monocrystalline silicon ingots, which are sliced into thin silicon

Get a quote

Powering the Future: Inside the Solar PV Cell

Conclusion The PV cell manufacturing process is a complex and precise endeavor that transforms raw materials into high-efficiency solar cells.

Get a quote

Solis Seminar【Episode 50】: How do inverters adapt to high-power PV

The PV module power of 182mm silicon wafers can exceed 540W, and the PV module power of 210mm silicon wafer exceeds 600W. Some module manufacturers have

Get a quote

Choosing the Correct Inverter for High Power M10 (182mm), G12

Choosing the Correct Inverter for High Power M10 (182mm), G12 (210mm) PV Modules Over the past few decades, mainly due to advances in technology and reduction in

Get a quote

How Do Inverters Adapt To High-Power PV Modules?

The PV module power of 182mm silicon wafers can exceed 540W, and the PV module power of 210mm silicon wafer exceeds 600W. Some module manufacturers have

Get a quote

Silicon wafers, cells, modules, inverters, China''s photovoltaic

According to customs data, China''s exports of monocrystalline silicon wafers with a diameter greater than 15.24 cm from January to November 2023 totaled 7.22 billion pieces. In

Get a quote

How Solar Silicon Wafers Are Made into Cells

How Solar Silicon Wafers Are Made into Cells. The process of transforming solar silicon wafers into cells involves several meticulous steps,

Get a quote

Solar Silicon Wafer Market: Trends, Opportunities and

The future of the solar silicon wafer market looks promising with opportunities in PV modules, inverters, solar cells, solar racking systems, and solar batteries. The global solar silicon wafer

Get a quote

A trio of manufacturers announce the first all ''Made in

Corning, Suniva and Heliene combine strengths to produce what will be the first solar module with polysilicon, wafers and cells made in the

Get a quote

A comprehensive review on the recycling technology of silicon

Table 4 represents the chemical etching processes adopted by various authors to recover silicon from silicon solar PV wafers. This technique eliminates silver electrodes, anti

Get a quote

Solar Wafers: Key to Efficient Solar Panels

Explore the role of solar wafers in efficient solar panels, their types, manufacturing process, and contribution to reducing carbon emissions in the

Get a quote

Guess what you want to know

-

Specifications and dimensions of photovoltaic panel silicon wafers

Specifications and dimensions of photovoltaic panel silicon wafers

-

Comoros exports photovoltaic module inverters

Comoros exports photovoltaic module inverters

-

Requirements for grid-connected photovoltaic inverters

Requirements for grid-connected photovoltaic inverters

-

Sales of photovoltaic grid-connected inverters in Côte d Ivoire

Sales of photovoltaic grid-connected inverters in Côte d Ivoire

-

Fiji makes photovoltaic inverters

Fiji makes photovoltaic inverters

-

Full range of photovoltaic inverters

Full range of photovoltaic inverters

-

Anti-islanding of photovoltaic inverters

Anti-islanding of photovoltaic inverters

-

Do photovoltaic inverters consume a lot of power

Do photovoltaic inverters consume a lot of power

-

Huawei amorphous silicon photovoltaic panels

Huawei amorphous silicon photovoltaic panels

-

Differences between three types of photovoltaic inverters

Differences between three types of photovoltaic inverters

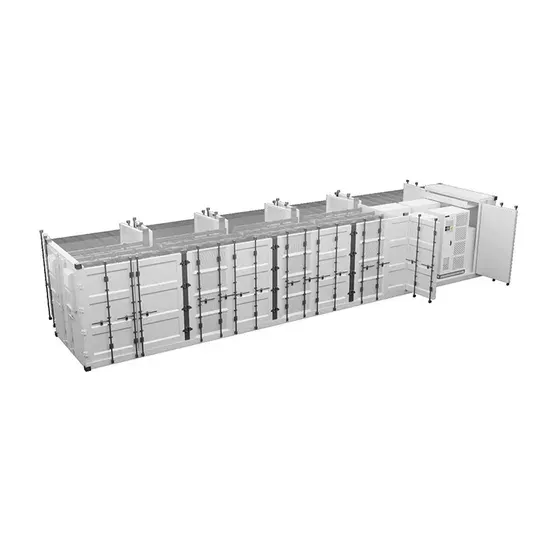

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

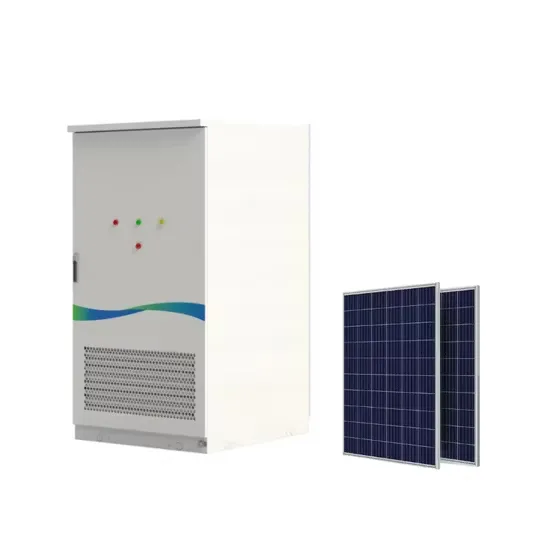

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.