Thermal Management for Energy Storage: Air or

Choosing the right cooling technology for Battery Energy Storage Systems (BESS) is crucial for performance and longevity. Explore air vs. liquid

Get a quote

Liquid Cooling Energy Storage Systems for Renewable Energy

In this article, we''ll explore how liquid cooling technology, particularly heat pipe cooling, is transforming energy storage and its integration with renewable energy sources.

Get a quote

Cooler Buildings, Stronger Grid: A New Approach to Air

The ESEAC cycle includes three key steps, each tied to a specific subsystem: Step 1: Charging —A dilute salt-based liquid desiccant is separated into a high-concentration

Get a quote

Why Water Cooling In Data Centers Is Not Always

Here''s how ''water-free'' cooling in data centers works, why it''s sometimes more efficient than air and liquid cooling, and how to decide if it''s

Get a quote

Thermochemical energy storage system for cooling and process

Energy harvested from the sun is capable of achieving the required residential and industrial energy demands. Thermal energy storage (TES) is a potential option for storing low

Get a quote

Battery Cooling Tech Explained: Liquid vs Air Cooling Systems

Air Cooling or Liquid Cooling, Which is Suitable? Ultimately, the choice depends on scale and requirements. Air cooling remains viable for low-C-rate or cost-sensitive systems

Get a quote

What is the liquid cooling energy storage strategy? | NenPower

Liquid cooling energy storage strategies involve the use of liquid-based solutions to store and manage energy efficiently, utilizing three essential components: 1. Thermal

Get a quote

Liquid Cooling Energy Storage: Why It''s the Coolest Innovation You Can

Now, imagine that same heat challenge for large-scale energy storage systems. As renewable energy adoption surges, managing the thermal stress of batteries has become a

Get a quote

Liquid Cooling in Energy Storage: Innovative Power Solutions

This article explores the benefits and applications of liquid cooling in energy storage systems, highlighting why this technology is pivotal for the future of sustainable energy.

Get a quote

What is Immersion Liquid Cooling Technology in Energy Storage

Immersion liquid cooling technology is an efficient method for managing heat in energy storage systems, improving performance, reliability, and space efficiency.

Get a quote

How liquid-cooled technology unlocks the potential of energy storage

Liquid-cooled battery energy storage systems provide better protection against thermal runaway than air-cooled systems. "If you have a thermal runaway of a cell, you''ve got this massive heat

Get a quote

CHOOSING BETWEEN AIR-COOLED AND LIQUID

When it comes to energy storage, selecting the appropriate cooling method is crucial for efficient and reliable operation. Two commonly used

Get a quote

Frequently Asked Energy Storage Questions

Absolutely – storage systems can incorporate equal, or greater, redundancy than conventional systems. It all depends on the demands of the application. Sometimes multiple chillers provide

Get a quote

Comprehensive review of energy storage systems technologies,

For enormous scale power and highly energetic storage applications, such as bulk energy, auxiliary, and transmission infrastructure services, pumped hydro storage and

Get a quote

Liquid Cooling Energy Storage: Why It''s the Coolest Innovation

Enter liquid cooling energy storage —a game-changer that''s redefining efficiency, safety, and sustainability in the energy sector. In this blog, we''ll dive into why this technology is

Get a quote

EXPLORING THE ADVANTAGES OF AIR-COOLED AND LIQUID-COOLED SYSTEMS

Introduction: Battery Energy Storage Systems (BESS) play a crucial role in modern energy management, providing a reliable solution for storing excess energy and balancing the

Get a quote

What is the liquid cooling energy storage strategy?

Liquid cooling energy storage strategies involve the use of liquid-based solutions to store and manage energy efficiently, utilizing three

Get a quote

Liquid Cooling Energy Storage: The Game-Changer You Can''t

Why Liquid Cooling Is Stealing the Spotlight in Energy Storage Imagine your smartphone battery surviving a marathon gaming session without breaking a sweat. Now scale

Get a quote

These 4 energy storage technologies are key to climate efforts

Underground thermal energy storage projects such as this create the possibility of storing waste heat from data centres, cooling processes and waste-to-energy sites below

Get a quote

Thermal Energy Storage

Thermal Energy Storage Thermal energy storage (TES) technologies heat or cool a storage medium and, when needed, deliver the stored thermal energy to meet heating or cooling

Get a quote

CHOOSING BETWEEN AIR-COOLED AND LIQUID-COOLED ENERGY STORAGE

When it comes to energy storage, selecting the appropriate cooling method is crucial for efficient and reliable operation. Two commonly used options are air-cooled and

Get a quote

Liquid Cooling Energy Storage: Why It''s the Coolest Innovation You Can

Enter liquid cooling energy storage —a game-changer that''s redefining efficiency, safety, and sustainability in the energy sector. In this blog, we''ll dive into why this technology is

Get a quote

EV Battery Cooling: Key Applications and Impact on

We will review the advantages of liquid cooling systems and how AI can assist car manufacturing by providing substantial help to product engineers working on

Get a quote

Energy Storage Liquid Cooling Container Design: The Future of

If you''re reading this, chances are you''re either an engineer tired of overheating battery packs, a project manager chasing energy efficiency, or just someone who''s wondered,

Get a quote

How liquid-cooled technology unlocks the potential of

Liquid-cooled battery energy storage systems provide better protection against thermal runaway than air-cooled systems. "If you have a thermal runaway of a

Get a quote

6 FAQs about [Can energy storage be done without a water cooling system ]

Are liquid cooled battery energy storage systems better than air cooled?

Liquid-cooled battery energy storage systems provide better protection against thermal runaway than air-cooled systems. “If you have a thermal runaway of a cell, you’ve got this massive heat sink for the energy be sucked away into. The liquid is an extra layer of protection,” Bradshaw says.

What is the difference between air cooled and liquid cooled energy storage?

The implications of technology choice are particularly stark when comparing traditional air-cooled energy storage systems and liquid-cooled alternatives, such as the PowerTitan series of products made by Sungrow Power Supply Company. Among the most immediately obvious differences between the two storage technologies is container size.

Why is electricity storage system important?

The use of ESS is crucial for improving system stability, boosting penetration of renewable energy, and conserving energy. Electricity storage systems (ESSs) come in a variety of forms, such as mechanical, chemical, electrical, and electrochemical ones.

What is underground thermal energy storage?

Underground thermal energy storage projects such as this create the possibility of storing waste heat from data centres, cooling processes and waste-to-energy sites below ground – and could have a big impact as the energy transition advances.

What is energy storage?

Energy storage is used to facilitate the integration of renewable energy in buildings and to provide a variable load for the consumer. TESS is a reasonably commonly used for buildings and communities to when connected with the heating and cooling systems.

What is thermal energy storage?

It involves storing excess energy – typically surplus energy from renewable sources or waste heat – to be used later for heating, cooling or power generation. Liquids such as water, or solid materials such as sand or rocks, can store thermal energy. Chemical reactions or changes in materials can also be used to store and release thermal energy.

Guess what you want to know

-

Water cooling structure design of energy storage system

Water cooling structure design of energy storage system

-

Can energy storage be done without a water cooling system

Can energy storage be done without a water cooling system

-

Do energy storage batteries need water cooling

Do energy storage batteries need water cooling

-

Huawei energy storage battery cooling

Huawei energy storage battery cooling

-

Liquid Cooling Energy Storage Container Supplier

Liquid Cooling Energy Storage Container Supplier

-

Liquid cooling standards for energy storage power station buildings

Liquid cooling standards for energy storage power station buildings

-

Fiji liquid cooling energy storage container supplier

Fiji liquid cooling energy storage container supplier

-

The difference between energy storage liquid cooling system and full liquid cooling

The difference between energy storage liquid cooling system and full liquid cooling

-

Energy Storage Container Liquid Cooling System

Energy Storage Container Liquid Cooling System

-

Huawei Liquid Cooling Energy Storage Container

Huawei Liquid Cooling Energy Storage Container

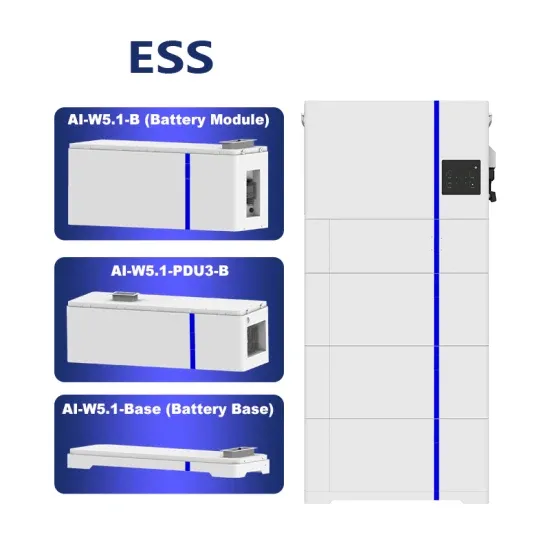

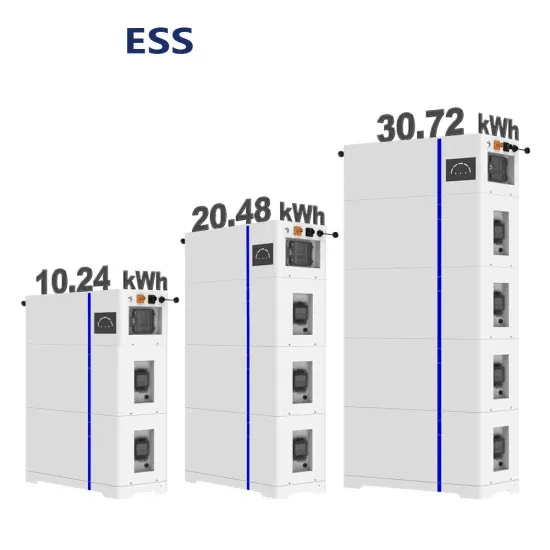

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.