Mechanical behaviour of photovoltaic composite structures: A

The subject of this work is the investigation of the effect of varying geometric and material properties of components at photovoltaic modules. It is apparent that XLWT is an

Get a quote

Solar Photovoltaic: SPECIFICATION, CHECKLIST AND GUIDE

As a package of optimized solution for project specific customization, we deliver product in which no field cutting / welding is required. Our material is suitable

Get a quote

Understanding Height and Clearance: Critical Design Parameters

Understanding the intricacies of utility-scale solar racking design is crucial for successful project implementation. One of the most fundamental aspects is the careful

Get a quote

Light and durable: Composite structures for

In several countries, building-integrated photovoltaics solutions could prospectively contribute to the growth of total installed photovoltaic (PV)

Get a quote

Solar Photovoltaic Projects

The references and articles below provide PV system basics, examples of the four common types of PV systems used to generate electric power, reviews of PV system components, lots on

Get a quote

BASF and Worldlight''s New Polyurethane-based PV

Germany-based BASF is set to unveil their PV frame that is co-created with Jiangsu Worldlight New Material Company Limited. They are a

Get a quote

Light and durable: Composite structures for building‐integrated

In several countries, building-integrated photovoltaics solutions could prospectively contribute to the growth of total installed photovoltaic (PV) capacity as they enable electricity

Get a quote

Advances in Mounting Structures for Photovoltaic

This article addresses the technical, aesthetic, and strategic problem of the limited attention paid to design and selection of materials in

Get a quote

Detailed Structural Commentary for Rooftop PV Arrays for

B.7. In areas of significant seismic activity (Seismic Category C, D, E or F), PV array covers no more than half the total area of the roof (all roofs included).

Get a quote

INSTALLATION MANUAL V2 22.05.2019.cdr

The system is a non-separately derived system. The following components have been evaluated for bonding as the fault current ground path: PV module, Mid Clamp, End

Get a quote

Solar Photovoltaic: SPECIFICATION, CHECKLIST AND GUIDE

The RERH specifications and checklists take a builder and a project design team through the steps of assessing a home''s solar resource potential and defining the minimum structural and

Get a quote

Solar Panel Brackets: The Ultimate Guide, types and best options.

Solar panel brackets are an essential component of any solar panel system. They are used to secure solar panels onto rooftops, ground mounts, or other structures.

Get a quote

Module Mounting Structures Design & Types for Rooftop Solar

Now, to achieve higher levels of generation, the optimum tilt of the modules is achieved by raising them on a mounting structure.

Get a quote

Understanding Height and Clearance: Critical Design

Understanding the intricacies of utility-scale solar racking design is crucial for successful project implementation. One of the most fundamental

Get a quote

Shingled design lightweight photovoltaic modules using

The expanding scale of the photovoltaic (PV) market has intensified the focus on PV module designs for diverse applications. Research actively pursues lightweight PV modules,

Get a quote

Photovoltaic Panel Height Standards: What You Need to Know in

The answer lies in photovoltaic panel height standards - the unsung hero of solar efficiency. Recent data from the International Renewable Energy Agency shows properly elevated PV

Get a quote

210 High-Power Modules Help Photovoltaic Composite Projects

Among all types of photovoltaic power plants, those used for agricultural solar lighting and fishing solar lighting come with the highest construction costs. This stems from the

Get a quote

Design Recommendations for Central Inverters in

When designing utility-scale solar energy projects, optimizing central inverters is a crucial aspect that project developers, EPCs, and

Get a quote

Dynamic analysis of multi-module floating photovoltaic platforms

Dynamic analysis of multi-module floating photovoltaic platforms with composite mooring system by considering tidal variation and platform configuration

Get a quote

Thornova Solar: your first choice for solar panels and components

Our solar panels with composite frames have received a fire rating up to A level and are TUV, UL, REACH and ROHS compliant. The volume resistivity of the composite frame GFRP is >10 14

Get a quote

FRP/GRP Module Mounting Structure

As a package of optimized solution for project specific customization, we deliver product in which no field cutting / welding is required. Our material is suitable for weather extremities -40 deg c

Get a quote

Advanced polymer encapsulates for photovoltaic devices − A review

This situation is evidencing the urgent need of the alternative sustainable energy resources [3]. Solar energy is the most-abundant renewable energy-resource and among the

Get a quote

Solar PV Installation Guidelines

The Solar PV Installation Guidelines are aligned with the National Solar PV Service Technician Qual - ificationand assists the Solar PV installer to use international best practices when

Get a quote

6 FAQs about [Photovoltaic composite project component height]

Can building-integrated photovoltaic solutions contribute to the growth of PV capacity?

In several countries, building-integrated photovoltaics solutions could prospectively contribute to the growth of total installed photovoltaic (PV) capacity as they enable electricity production with minimal impact on free land.

How much weight does a PV system add to a roof?

A conventional PV system that includes racking materials will add approximately 6 pounds per square foot of dead load to the roof or structure, though actual weights can vary for different types of systems. Wind will add live loads; the magnitude of live loads will depend on the geographic region and the final PV system.

What is the minimum array area requirement for a solar PV inverter?

Although the RERH specification does not set a minimum array area requirement, builders should minimally specify an area of 50 square feet in order to operate the smallest grid-tied solar PV inverters on the market.

Why do rooftop solar panels have an elevated structure?

The elevated structure prevents the trailing panels free from the successive row of panels. During the design, the available parameters for any rooftop solar projects would be Tilt angle based on the location, panel length and width from the datasheet, and desired mount height, that is, above the roof surface.

What is a structural PV array mounting requirements checklist?

t Guidelines (the Guidelines), also called “Step 1: Structural PV Array Mounting Requirements Checklist” (the “Checklist”). It describes the structural engineering principles and assumptions behind the Guidelines Checklist and delineates how the document conforms to the Internati

What inputs are used to design a solar roof?

Inputs such as location (latitude-longitude), building height, roof tilt, solar module dimension and weight, type of roof, and fixing methods (e.g., the clamps used to affix the modules to the roof) are used in order to generate guidelines on the structure design, additional dead load on the roof, as well as the dynamic load on the roof.

Guess what you want to know

-

Photovoltaic inverter component manufacturing project

Photovoltaic inverter component manufacturing project

-

Photovoltaic Module Project Plan

Photovoltaic Module Project Plan

-

Congo Solar Photovoltaic Panel Project

Congo Solar Photovoltaic Panel Project

-

Uzbekistan Photovoltaic Power Generation and Energy Storage Project

Uzbekistan Photovoltaic Power Generation and Energy Storage Project

-

Belarus photovoltaic module project

Belarus photovoltaic module project

-

Nepal Communication Base Station Photovoltaic Power Generation Project

Nepal Communication Base Station Photovoltaic Power Generation Project

-

Huawei Timor-Leste photovoltaic module project

Huawei Timor-Leste photovoltaic module project

-

Photovoltaic Module Renewal Project

Photovoltaic Module Renewal Project

-

Huawei Barbados photovoltaic module project

Huawei Barbados photovoltaic module project

-

Singapore High-Efficiency Photovoltaic Module Project

Singapore High-Efficiency Photovoltaic Module Project

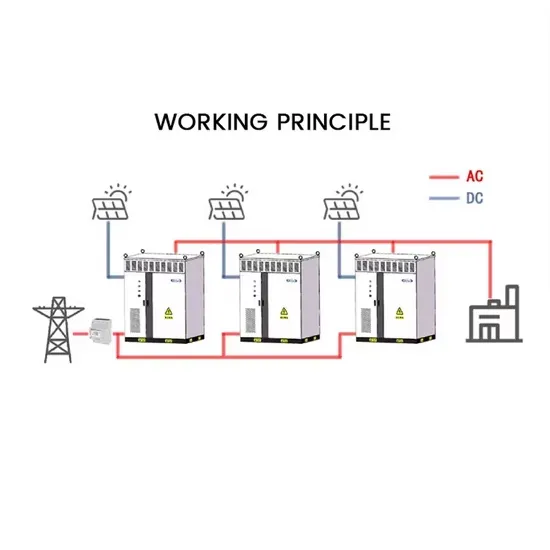

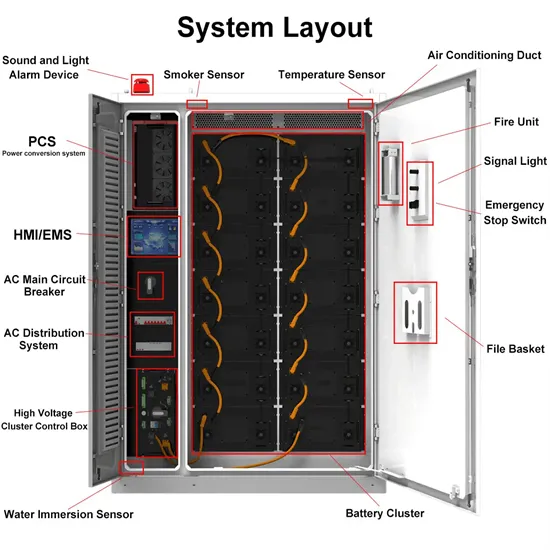

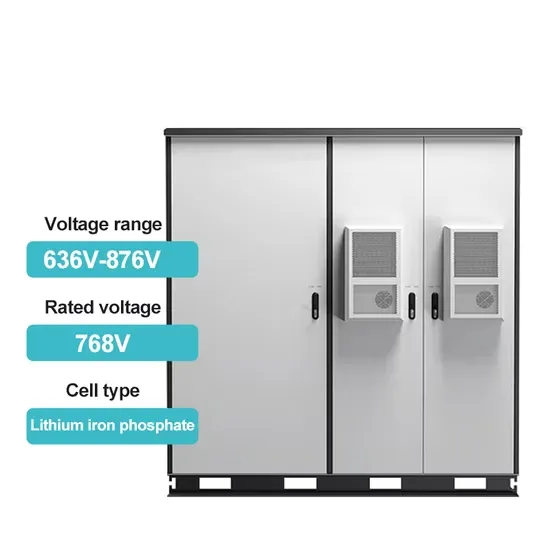

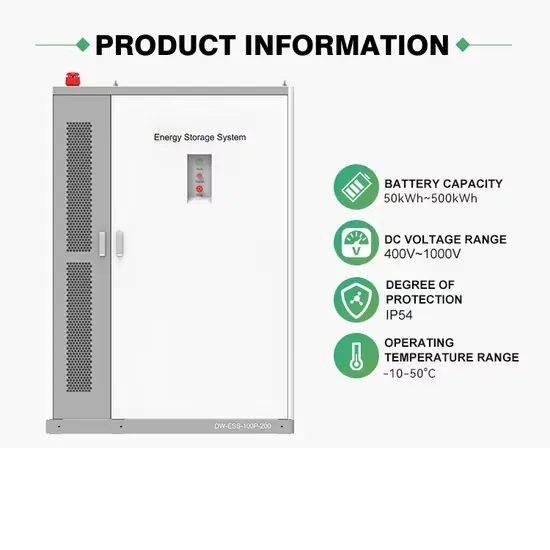

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.