Double the strengths, double the benefits

In the ever-evolving world of photovoltaic technology, double glass solar modules are emerging as a game-changer. By encapsulating solar cells between two layers of glass,

Get a quote

About the advantages of double-sided double-glass

Solar panels that can generate electricity on both sides are called bifacial modules, and are generally in the form of double-glazing. This article compiles

Get a quote

The weekend read: Double glass can spell double

Problems with glass-glass module lamination can result in compromised quality. The module can bow either after lamination or in the

Get a quote

What is the Double Glass (Dual Glass) Photovoltaic Solar Panel?

Glass-glass module structures (Dual Glass or Double Glass) is a technology that uses a glass layer on the back of the modules instead of the traditional polymer backsheet.

Get a quote

Double the strengths, double the benefits

In the ever-evolving world of photovoltaic technology, double glass solar modules are emerging as a game-changer. By encapsulating solar cells

Get a quote

Dual-glass vs glass-backsheet: The winning formula

Our dual glass modules use the same internal circuit connection as a traditional glass-backsheet module but feature heat-strengthened glass on

Get a quote

About the advantages of double-sided double-glass modules and

Solar panels that can generate electricity on both sides are called bifacial modules, and are generally in the form of double-glazing. This article compiles the advantages of double-sided

Get a quote

Slenergy N-Type bifacial double glass monofacial module 425W

High Efficiency Leading module efficiency in industry, up to 21.8% Double Sided Power Generation Bifaciality is up to 80%, up to 30% more energy yield than conventional

Get a quote

What is the difference between a double-sided double-glass n

The difference between double-sided double-glass n-type monocrystalline solar photovoltaic module and ordinary components is reflected in multiple dimensions, from core

Get a quote

What are the advantages of dual-glass Dualsun modules?

Dual-glass type modules (also called double glass or glass-glass) are made up of two glass surfaces, on the front and on the rear with a thickness of 2.0 mm each.

Get a quote

Dual-glass vs glass-backsheet: The winning formula for bifacial

Our dual glass modules use the same internal circuit connection as a traditional glass-backsheet module but feature heat-strengthened glass on both sides. We produce the

Get a quote

The Performance of Double Glass Photovoltaic Modules under

Double glass module contains two sheets of glass, whereby the back sheet is made of heat strengthened (semi-tempered) glass to substitute the traditional polymer backsheet.

Get a quote

What is the Double Glass Photovoltaic Solar Panel?

What is the Double Glass Photovoltaic Solar Panel? Glass-glass module structures (Dual Glass or Double Glass) is a technology that uses a glass

Get a quote

240118 425R 组件 IT 英文 待确认版

1 5 10 Standard Module Linear Performance Warranty 15 20 25 30 N-Type Bifacial Double Glass Module Linear Perlormance Warranty 1.00% 1st-year Degradation

Get a quote

What is the Double Glass Photovoltaic Solar Panel?

What is the Double Glass Photovoltaic Solar Panel? Glass-glass module structures (Dual Glass or Double Glass) is a technology that uses a glass layer on the back of the modules instead of

Get a quote

425w N-Type Bifacial Double Glass Module (Black Pro) DAS

Ref: DAS-DH108NA425w Bifacial Double Glass Module Maximum Module Efficiency 22.3%Download Datasheet hereFor any order greater than 5 panels, contact us via the form

Get a quote

What is the Double Glass (Dual Glass) Photovoltaic

Glass-glass module structures (Dual Glass or Double Glass) is a technology that uses a glass layer on the back of the modules instead of the

Get a quote

Bifacial Double Glass Module (Black Pro) DAS-DH108NA

Bifacial Double Glass Module (Black Pro) DAS-DH108NA 420W~440W Key Features High Efficiency Leading module efficiency in industry, up to 22.5%

Get a quote

JA 450W Bifacial Black Frame

Utilising the latest technology the n-type Bifacial from JA Solar is a high efficiency double glass module. Featuring mono 16BB cells on both sides of the module

Get a quote

JinkoSolar: Transparent backsheet vs dual glass

Transparent backsheet can successfully decrease module weight and the difference between the glass-transparent backsheet module and the

Get a quote

JinkoSolar: Transparent backsheet vs dual glass

Compared with dual glass, the transparent backsheet can successfully decrease module weight and the difference between the glass-transparent backsheet module and the

Get a quote

The weekend read: Double glass can spell double trouble

Problems with glass-glass module lamination can result in compromised quality. The module can bow either after lamination or in the field, particularly when frameless.

Get a quote

What are Double Glass Solar Panels?

These are known as Double-Glass designs (solar panels with double glass or glass solar panels). The double glass module, as the name implies, is a construction in which

Get a quote

6 FAQs about [Double glass module back]

What is a dual glass module?

Our dual glass modules use the same internal circuit connection as a traditional glass-backsheet module but feature heat-strengthened glass on both sides. We produce the back glass with a unique drilling technique that ensures the reliability of both the junction box installation and the module.

What is a glass-backsheet module?

In the case of a glass-backsheet module, not only is the upper glass layer thicker (3.2 mm versus 2.0 mm) but also this layer is fully tempered glass, whereas in the case of a thickness of 2.0 mm, the glass is only semi-tempered due to technical limitations of the tempering process.

What is the difference between glass-transparent backsheet and dual glass?

Along with the size increase, the module weight is also increasing. Compared with dual glass, the transparent backsheet can successfully decrease module weight and the difference between the glass-transparent backsheet module and the dual glass alternative increases with the growing module size.

Are glass-glass modules frameless?

Glass-glass modules can also be frameless, which helps eliminate the cost of an extruded aluminum frame. However, glass-glass models with frames have a lower risk of breakage. As a result, most glass-glass modules come with frames in place. Compared with standard glass backsheet technology, framed modules with two layers of glass are heavier.

What changes have been made in glass-glass modules?

In the case of Glass-Glass modules, an important change has been made by replacing EVA with polyolefins as an encapsulating substance. This is due to the free radicals generated during the EVA cross-link lamination process. Traditional backsheets are somewhat permeable to free radicals, but the double glass module is not.

Why should you choose a dual-glass module?

From this point of view, the structural design of our dual-glass modules overcomes problems such as the outdoor degradation-induced material aging and the power attenuation that frequently affects traditional backsheets. In addition, our design avoids distinctive weak points in thin-film modules, such as low efficiency and high vulnerability.

Guess what you want to know

-

Double glass module monocrystalline

Double glass module monocrystalline

-

Double glass module manufacturer in the Netherlands

Double glass module manufacturer in the Netherlands

-

Angola double glass module manufacturer

Angola double glass module manufacturer

-

Double glass module manufacturers

Double glass module manufacturers

-

Double glass module back

Double glass module back

-

Photovoltaic module 72 double glass size

Photovoltaic module 72 double glass size

-

Photovoltaic carport double glass module

Photovoltaic carport double glass module

-

Photovoltaic panels monocrystalline silicon double glass

Photovoltaic panels monocrystalline silicon double glass

-

Double glass single glass monocrystalline silicon components

Double glass single glass monocrystalline silicon components

-

Yaounde photovoltaic enterprise double glass solar panels

Yaounde photovoltaic enterprise double glass solar panels

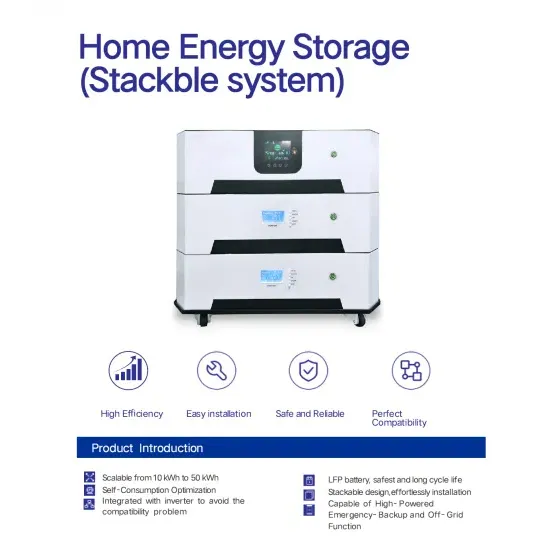

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.