Lithium Battery Pack Assembly: A Comprehensive Guide

At the heart of this burgeoning industry lies a meticulously orchestrated assembly process, where individual lithium-ion cells are transformed into powerful energy storage systems.

Get a quote

Battery Pack Assembly: Techniques and Materials Used

Electric vehicles rely on lithium-ion batteries for energy storage, making the battery pack the heart of an EV. Its assembly involves intricate

Get a quote

Lithium-ion batteries and the future of sustainable energy: A

Lithium-ion batteries (LIBs) have become a cornerstone technology in the transition towards a sustainable energy future, driven by their critical roles in electric vehicles, portable electronics,

Get a quote

Battery Pack Assembly: Techniques and Materials Used

Electric vehicles rely on lithium-ion batteries for energy storage, making the battery pack the heart of an EV. Its assembly involves intricate processes to ensure reliability, energy

Get a quote

How to Assemble a Lithium Battery Pack: Step-by-Step Guide for

Assembling a lithium battery pack requires careful planning, the right tools, and a thorough understanding of series and parallel configurations. By following this step-by-step

Get a quote

Key Points of Lithium Battery PACK Manufacturing

Dive into the detailed process behind these essential energy storage solutions! From selecting and matching battery cells to assembling,

Get a quote

Complete Guide to Lithium Battery Pack Design and Assembly

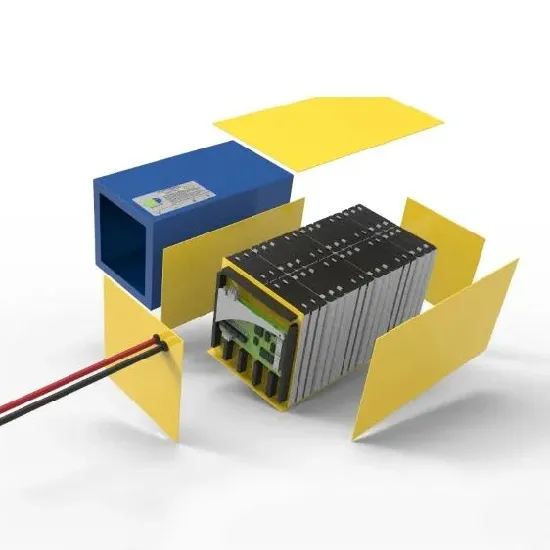

A lithium battery pack is not just a simple assembly of batteries. It is a highly integrated and precise system project. It covers multiple steps, including cell selection,

Get a quote

Steps to Assemble a DIY Lithium Battery Kit

Assembling a DIY lithium battery kit offers both flexibility and satisfaction, enabling you to create a custom energy storage solution tailored to your specific needs. Whether for

Get a quote

Beginner-Friendly Tips for Assembling Lithium Battery

Effective planning lays the foundation for a reliable lithium battery pack. You should start by defining the application requirements, such as

Get a quote

High-Efficiency Lithium Battery Module PACK Production Lines

Discover advanced lithium battery module PACK production lines featuring automated assembly, precision welding, rigorous testing, and customizable

Get a quote

Lib India Lithium Ion Batteries | Lib India

LIB India is known as a next generation energy storage company that builds high-performance, safe, and reliable lithium ion batteries and BMS to serve macro to micro energy storage

Get a quote

Beginner-Friendly Tips for Assembling Lithium Battery Packs

Effective planning lays the foundation for a reliable lithium battery pack. You should start by defining the application requirements, such as voltage, capacity, and size constraints.

Get a quote

How to Build a Lithium Ion Battery Pack? A Step by Step Guide

In this article, we will have an in-depth discussion on how to build a lithium ion battery pack? We will provide a step by step guide that we hope will help you understand the

Get a quote

Prismatic Lithium Battery Pack Assembly Line Energy

This customized production line is mainly used to complete the assembly, testing, and welding functions of the square shell energy storage lithium battery pack

Get a quote

Advanced Lithium Battery Assembly Equipment for ESS

In the evolving landscape of energy storage, lithium battery assembly equipment plays a vital role in determining the efficiency, safety, and scalability of battery module

Get a quote

ESS Energy Storage System Lithium Ion Battery Pack

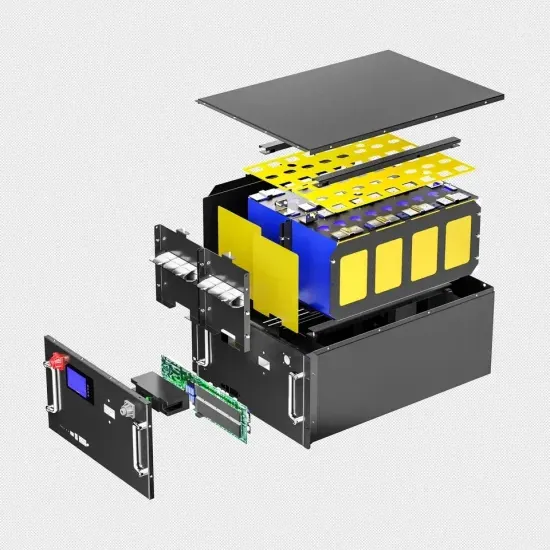

Product Description This battery pack assembly line is a production system used in the manufacturing of prismatic battery packs like ESS (Energy Storage

Get a quote

Lithium-ion Battery Module and Pack Production Line

In the future, lithium-ion module and pack production lines will continue to play a key role as energy storage technology continues to

Get a quote

Lithium battery factory in China, Lithium battery

Lithium battery factory in China, Lithium battery manufacturerWe produce lithium battery cell and relative new energy products, meanwhile, we are do recycle of

Get a quote

Prismatic Aluminum Lithium-ion Battery Module Assembly Line

Prismatic Aluminum Battery Module Assembly Line is engineered for high-precision, high-output manufacturing of energy storage battery packs. With a scalable architecture and fully

Get a quote

Lithium-Ion Battery Assembly Process & Key Stages Explained

Explore a step-by-step guide on lithium battery pack assembly and cell making equipment. Learn the full process with expert insights.

Get a quote

Production Line Guide | CHISAGE Battery Pack Process Flow

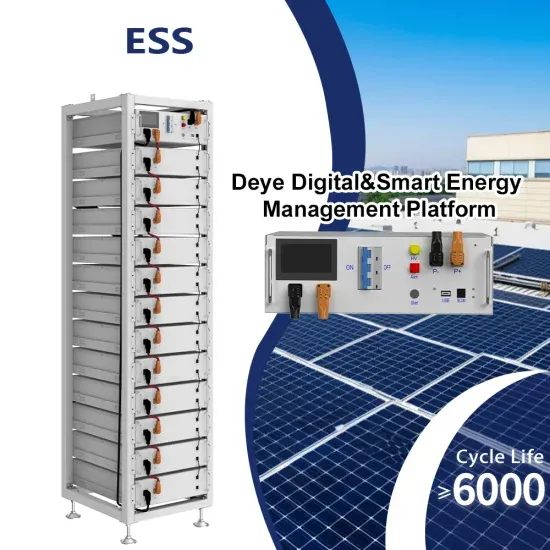

Production Line Overview Chisage ESS has been in the field of solar battery for many years and is committed to producing high-quality energy storage battery packs. lithium

Get a quote

Semi-Automatic Lithium-ion Battery Assembly Line

Conclusion In conclusion, Semco Infratech''s semi-automatic lithium battery pack assembly line represents a long step in energy storage

Get a quote

Li-Ion battery assembly lines for energy storage systems

Our expertise encompasses the design and delivery of cutting-edge equipment for assembling lithium-ion and sodium-ion batteries, catering to applications

Get a quote

Current and future lithium-ion battery manufacturing

Introduction Lithium-ion batteries (LIBs) have been widely used in portable electronics, electric vehicles, and grid storage due to their high energy density, high power

Get a quote

Key Points of Lithium Battery PACK Manufacturing Process

Dive into the detailed process behind these essential energy storage solutions! From selecting and matching battery cells to assembling, testing, and packaging, discover the

Get a quote

Li-Ion battery assembly lines for energy storage systems

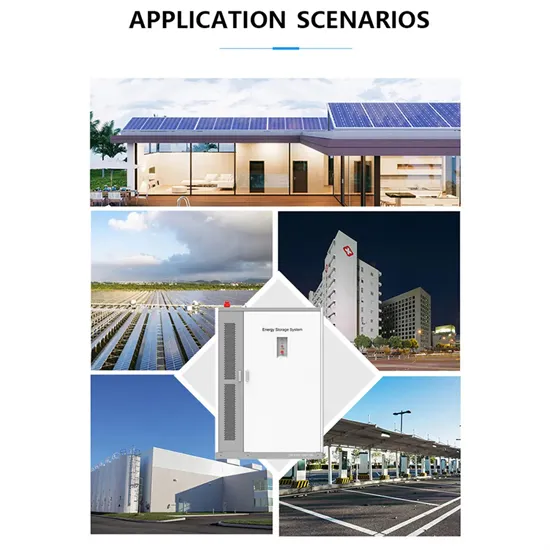

Our expertise encompasses the design and delivery of cutting-edge equipment for assembling lithium-ion and sodium-ion batteries, catering to applications ranging from residential and

Get a quote

Assembly and Application of Energy Storage Lithium

What is an energy storage lithium battery pack? Lithium battery pack generally refers to assembled batteries, mainly refers to the processing

Get a quote

Lithium-Ion Battery Assembly Line Process Explained

As the demand for electric vehicles (EVs) and energy storage solutions surges, the efficiency of lithium-ion battery assembly lines plays a

Get a quote

Guess what you want to know

-

North Macedonia lithium battery energy storage cabinet assembly plant

North Macedonia lithium battery energy storage cabinet assembly plant

-

Energy storage lithium battery assembly photovoltaic power generation

Energy storage lithium battery assembly photovoltaic power generation

-

Huawei Energy Storage Lithium Battery Assembly Factory

Huawei Energy Storage Lithium Battery Assembly Factory

-

Energy storage lithium battery assembly

Energy storage lithium battery assembly

-

How much does a two-kilowatt-hour energy storage lithium battery cost

How much does a two-kilowatt-hour energy storage lithium battery cost

-

South African lithium battery energy storage system

South African lithium battery energy storage system

-

Saudi Arabia off-grid lithium battery energy storage 30kw inverter

Saudi Arabia off-grid lithium battery energy storage 30kw inverter

-

Djibouti Huijue lithium battery energy storage cabinet

Djibouti Huijue lithium battery energy storage cabinet

-

How much does energy storage lithium battery retail for

How much does energy storage lithium battery retail for

-

French energy storage lithium battery manufacturer

French energy storage lithium battery manufacturer

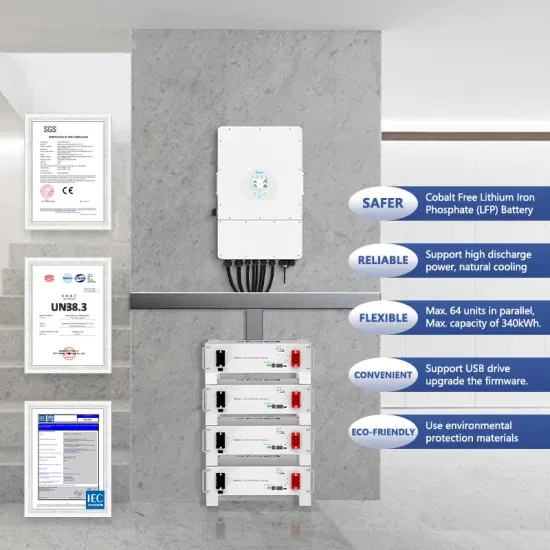

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.