PV inverter with decoupled active and reactive power control to

This paper proposes a grid-tied PV inverter installed at the low voltage side of a distribution grid. The architecture considers the operation of a grid-tied inverter and its

Get a quote

Alternate method for evaluating power-temperature derating

The heart of grid-connected solar power plant operation is the performance of grid tie inverter. The inverter will operate only when the grid is alive and its main function is to convert the solar

Get a quote

HYBRID POWER SYSTEMS (PV AND FUELLED

This guideline has one section for sizing the components of a hybrid system where the fuelled generator is being used as a backup to provide power when there is insufficient

Get a quote

Renac Inverter Temperature De-rating

Temperature derating prevents the sensitive semiconductors in the inverter from overheating. Once the permissible temperature on the monitored components is reached, the inverter shifts

Get a quote

Derating of Solar Inverters Due to High Operating Temperature

This report delves into the causes, effects, and mitigation strategies for thermal derating in solar inverters, providing a comprehensive understanding of this issue.

Get a quote

Design and field implementation of smart grid-integrated control of PV

Electric utilities typically impose restrictions on PV hosting capacity or curtail solar distributed generation to avoid those operational concerns. PV integration can be enhanced,

Get a quote

How large of a problem is thermal derating?

In its Inverter Scorecard, PV Evolution Labs examines thermal derating, a long-known problem among experts. With the data the lab collects, it provides insights as to how

Get a quote

Data-Backed Derating Curves for Solar Inverters by Climate

Stop guessing your solar output. Learn how data-backed inverter derating curves, tailored to your climate, unlock accurate performance predictions and maximize your system''s

Get a quote

Inverter Temperature Degrading

Dear Cleyson, Thank you for your question. In the simulation, the inverter derating will depend on the inverter temperature. By default, the inverter temperature is the same as

Get a quote

Technical Information

This document describes in graphic and tabular form the efficiency profile and the derating behavior in accordance with DIN EN 50524:2010 of the following SMA inverters (status:

Get a quote

Microsoft Word

Each modelling tool applies its irradiance and performance model algorithms before a number of derating factors are applied to determine the final system output. PVsyst provides extensive

Get a quote

The added value of coordinated PV inverter control

The sensitivity of inverter size Coordinated Inverter Control Summer week *DC-AC derating factor 17% (PV system losses) ** 130% of the nominal PV output [kWp] Winter week Thank You!

Get a quote

What Causes Derating On Solar Inverter

This technical document illustrates the derating behavior of inverters and its implications for performance, emphasizing the importance of managing operating conditions

Get a quote

SUNNY BOY / SUNNY TRIPOWER Temperature derating

Temperature derating occurs when the inverter reduces its power in order to protect components from overheating. This document explains how inverter temperature is controlled, what causes

Get a quote

Employing predictive maintenance to reduce

Explore PV maintenance strategies to tackle solar inverter overload and derating. Learn advanced predictive detection methods, preventive tips, and solutions

Get a quote

Master thesis.pdf

The Smart Derating of Switching Devices for Designing More Reliable PV Inverters Master thesis was conducted in Aalborg University, Institute of Energy Technology, as part of the 10th

Get a quote

Advanced Inverter Technology for High Penetration Levels of

2 Utility Concerns about the Impact of High-Penetration PV on Medium-Voltage Feeders As a leading supplier of inverters for large PV generating projects, Satcon has participated in

Get a quote

How large of a problem is thermal derating?

In its Inverter Scorecard, PV Evolution Labs examines thermal derating, a long-known problem among experts. With the data the lab collects,

Get a quote

Long read: Delaying derating – pv magazine Australia

A quick look towards inverter data sheets shows that most inverters can maintain operations at a maximum ambient temperature of around 60°C, but start derating at slightly

Get a quote

Derating de Temperatura dos Inversores Fotovoltaicos

Como funciona o derating nos inversores de string? Para descobrir se a função derating está sendo acionada de forma eventual ou como consequência de

Get a quote

Employing predictive maintenance to reduce temperature derating

Explore PV maintenance strategies to tackle solar inverter overload and derating. Learn advanced predictive detection methods, preventive tips, and solutions to optimize system performance

Get a quote

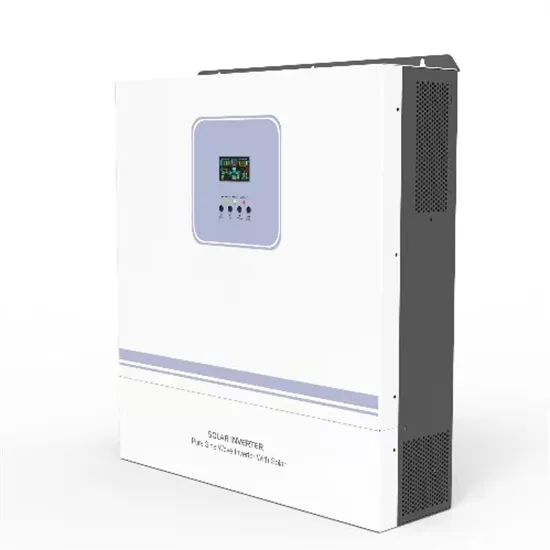

Understanding Different Types of Solar Inverters

This is a guide to types of solar inverters based on output waveforms, power levels, applications, grid connections, and control methods.

Get a quote

Status Messages Derating, Derating Idc, derat. Idc

If the inverter has fans (e.g. all Sunny Mini Central and Sunny Boy SB 3300/3800 models), also check whether the fans are functional and not contaminated. Electric current

Get a quote

6 FAQs about [PV inverter autonomous derating]

What is derating a solar inverter?

Derating is the controlled reduction of the inverter power. In normal operation, inverters operate at their maximum power point. At this operating point, the ratio between PV voltage and PV current results in the maximum power. The maximum power point changes constantly depending on solar irradiation levels and PV module temperature.

Does temperature derating affect a PV inverter?

In this case, the maximum DC voltage of the inverter acts more as a technical boundary than a normal operating curve. There is no PV array operating point that requires the inverter to feed in at full power at temperatures above 31°C (at 800 V). On principle, temperature derating has no negative effects on the inverter.

What is a temperature derating inverter?

Temperature derating prevents the sensitive semiconductors in the inverter from overheating. Once the permissible temperature on the monitored components is reached, the inverter shifts its operating point to a reduced power level. The power is reduced in steps. In extreme cases, the inverter will shut down completely.

What causes a PV system to derate?

Derating rarely occurs when the PV system is well matched. Derating is more common when the inverter is undersized relative to the PV array (see Section 2, page 2 for the causes of frequent temperature derating). You can determine the ideal design for your PV system with the "Sunny Design" software.

Why does a PV inverter not dissipate heat?

The inverter cannot dissipate heat due to unfavorable installation conditions. The inverter is operated in direct sunlight or at high ambient temperatures that prevent adequate heat dissipation. The PV array and inverter are mismatched (power of the PV array compared to the power of the inverter).

How do SolarEdge inverters & power optimizers work?

SolarEdge Inverters and Power Optimizers operate at full power and full current up to a specified maximum ambient temperature. When the ambient temperature exceeds the specified maximum, they continue to operate at reduced ratings to prevent damage to the devices.

Guess what you want to know

-

Belize PV Inverter Price

Belize PV Inverter Price

-

Huawei Tunisia PV Inverter

Huawei Tunisia PV Inverter

-

Huawei Australia PV inverter

Huawei Australia PV inverter

-

Croatia Electric PV Inverter Prices

Croatia Electric PV Inverter Prices

-

PV inverter direct AC

PV inverter direct AC

-

Smart Solar PV Inverter

Smart Solar PV Inverter

-

Georgia PV Energy Storage Inverter Wholesale

Georgia PV Energy Storage Inverter Wholesale

-

Thailand PV inverter requirements

Thailand PV inverter requirements

-

PV system inverter cost

PV system inverter cost

-

Cook Islands Solar PV Panel Inverter

Cook Islands Solar PV Panel Inverter

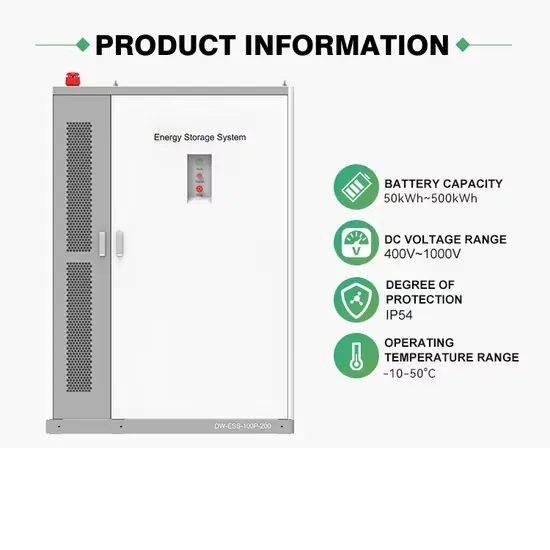

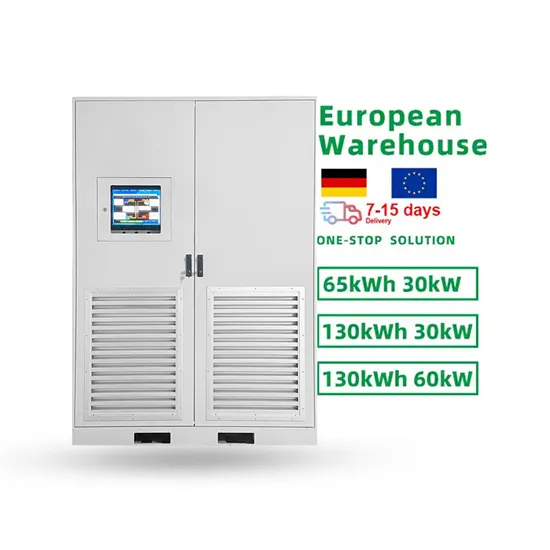

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.