How internal resistance affects battery performance

Internal resistance plays a significant role in battery performance, affecting efficiency, power output, and lifespan. In lithium-ion batteries, it

Get a quote

A multi-parameter analysis of iron/iron redox flow batteries: effects

Iron/iron redox flow batteries (IRFBs) are emerging as a cost-effective alternative to traditional energy storage systems. This study investigates the impact of key operational characteristics,

Get a quote

Factors affecting the performance of the Zn-Ce redox flow battery

An understanding of these effects and its application in the redox flow battery enabled both the coulombic and cell potential efficiencies to be maintained at relatively high values, 90% and

Get a quote

Overview of the factors affecting the performance of vanadium

Redox flow batteries are being utilised as an attractive electrochemical energy storage technology for electricity from renewable generation. At present, the global installed capacity of redox flow

Get a quote

Evaluation of Asymmetric Flow Rates for Better

To mitigate the effect of electrolyte imbalance, herein we report an experimental study on the effect of using asymmetric flow rates in the negative

Get a quote

Study on the Influence of the Flow Factor on the Performance of

One factor that critically affects battery efficiency is the flow rate. The flow rate is related to the charge or discharge current of the battery and the electrolyte flow rate. It also

Get a quote

Future perspective on redox flow batteries: aqueous

Factors affecting cell performance in aqueous and nonaqueous electrolytes Stabilities The stabilities of aqueous and nonaqueous flow batteries depend on the selections

Get a quote

Battery Life and Performance Factors | Greentech

Here is a summary of four main factors (cyclic life, depth of discharge, temperature, recharge rate) affecting the battery performance and life.

Get a quote

Test factors affecting the performance of zinc-air battery

Zinc–air batteries provide a great potential for future large-scale energy storage. We assess the test factors that mainly affect the measured power density of the zinc–air battery.

Get a quote

Influence of temperature on performance of all vanadium redox flow

The main mass transfer processes of the ions in a vanadium redox flow battery and the temperature dependence of corresponding mass transfer properties of the ions were

Get a quote

Engineers evaluate the factors affecting battery performance

The study collated information from many other reports regarding the performance of diverse LT-AEs, for example an antifreezing hydrogel electrolyte for an aqueous Zn/MnO2 battery; and an

Get a quote

Evaluation of Asymmetric Flow Rates for Better Performance

To mitigate the effect of electrolyte imbalance, herein we report an experimental study on the effect of using asymmetric flow rates in the negative and positive half-cells.

Get a quote

Overview of the factors affecting the performance of vanadium

The effects of the key parameters on redox flow battery performance are reviewed. Electrode activation and felt compression are the most significant factors. Electrolyte additive and flow

Get a quote

Quantifying the factors limiting rate performance in battery

The authors employ a semi-empirical method to fit published battery capacity-rate data to extract the characteristic time associated with charge/discharge. These characteristic

Get a quote

An Investigation into Factors Affecting the Iron Plating

Abstract and Figures The all-Iron flow battery utilizes the iron II/III redox couple at the positive electrode and the iron II/0 reaction at the negative

Get a quote

Factors Affecting Car Battery Performance

Factors Affecting Car Battery Performance: Optimizing Longevity and Reliability Introduction: The car battery is a crucial component of every vehicle, providing power for engine ignition,

Get a quote

The Science of Battery Performance: What You Need

We''ll delve into the key factors that impact battery performance, including temperature, humidity, age, overcharging, and depth of discharge.

Get a quote

Maximizing Flow Battery Efficiency: The Future of Energy Storage

What factors affect flow battery efficiency? Several factors influence flow battery efficiency, including electrolyte composition, membrane and electrode materials, operating

Get a quote

Factors affecting the performance of the Zn-Ce redox flow

Flow velocity at the low Reynolds number in the cell (Re. <200) had little impact on the electrochemical cell performance. Depletion of the cerium. species became an issue for long

Get a quote

The Science of Battery Performance: What You Need to Know

We''ll delve into the key factors that impact battery performance, including temperature, humidity, age, overcharging, and depth of discharge. We''ll also discuss how

Get a quote

Evaluation of Asymmetric Flow Rates for Better Performance

Electrolyte imbalance caused by water and ion crossover is one of the main factors affecting the capacity of vanadium redox flow battery system over cycling. Ion

Get a quote

Modeling and performance optimization of vanadium redox flow

In this work, we investigate VRFB performance optimization focusing on two end-user-friendly parameters: current density and electrolyte flow rate. We presented an

Get a quote

Factors affecting flow battery performance

The factors affecting the performance of flow batteries are analyzed and discussed, along with the feasible means of improvement and the cost of different types of flow

Get a quote

Electric Circuits Factors affecting voltage, amperage, resistance

Introduction: (Initial Observation) In a closed electric circuit, resistance of the components and the voltage of power source are affecting the electric current. Current is the rate of flow of

Get a quote

Overview of the factors affecting the performance of vanadium

There are several parameters that significantly govern redox flow battery performance amongst which electrode activation, electrode material, felt compression,

Get a quote

Fe / Fe Flow Battery

This chapter describes the operating principles and key features of the all-iron flow battery (IFB). This energy storage approach uses low-cost iron metal (Fe) ions for both the

Get a quote

A multi-parameter analysis of iron/iron redox flow

Iron/iron redox flow batteries (IRFBs) are emerging as a cost-effective alternative to traditional energy storage systems. This study investigates the impact of

Get a quote

6 FAQs about [Factors affecting flow battery performance]

What factors affect battery efficiency?

In addition, a PSO type technique is introduced to optimize the battery design. Neither study considers activation and concentration overpotentials. One factor that critically affects battery efficiency is the flow rate. The flow rate is related to the charge or discharge current of the battery and the electrolyte flow rate.

How does flow factor affect battery efficiency?

Linking with Eq. 22, the higher the current, the greater the flow rate needed; therefore, the pressure losses will increase, implying a higher need for pump power. This probably directly limits the value of the flow factor. Knowing the optimum flow factor for battery operation is of great interest to optimize battery efficiency.

Does flow rate affect battery power?

The flow rate of the battery directly affects the pressure losses that occur and, by extension, the power that the pumps must provide for the battery to operate. However, as studies such as Ref. 20 have reported, flow rate also influences battery voltage and shunt currents, thus affecting the battery power.

How does temperature affect battery performance?

Temperature is one of the most significant factors affecting battery performance. Extreme temperatures, whether hot or cold, can reduce a battery’s capacity and lifespan. High temperatures can cause batteries to degrade more quickly, while low temperatures can reduce a battery’s ability to provide energy.

How does a flow factor affect system efficiency?

The results show that the lower the current imposed for charging and discharging, the more flexibility there is for choosing a flow factor that maximizes system efficiency. The variation of currents has a direct influence on the pressure losses.

How does current affect flow factor?

The variation of currents has a direct influence on the pressure losses. Linking with Eq. 22, the higher the current, the greater the flow rate needed; therefore, the pressure losses will increase, implying a higher need for pump power. This probably directly limits the value of the flow factor.

Guess what you want to know

-

South Sudan 5G Communication Base Station Flow Battery Construction Project

South Sudan 5G Communication Base Station Flow Battery Construction Project

-

Albania Vanadium Flow Battery Energy Storage Station

Albania Vanadium Flow Battery Energy Storage Station

-

Zinc flow battery

Zinc flow battery

-

Benin all-vanadium redox flow battery

Benin all-vanadium redox flow battery

-

Seychelles High Performance Energy Storage Battery Company

Seychelles High Performance Energy Storage Battery Company

-

All-vanadium redox flow battery market share

All-vanadium redox flow battery market share

-

Which type of flow battery is better

Which type of flow battery is better

-

Alkaline zinc-iron flow battery stability

Alkaline zinc-iron flow battery stability

-

1GWh flow battery

1GWh flow battery

-

Guinea communication base station flow battery lightning protection

Guinea communication base station flow battery lightning protection

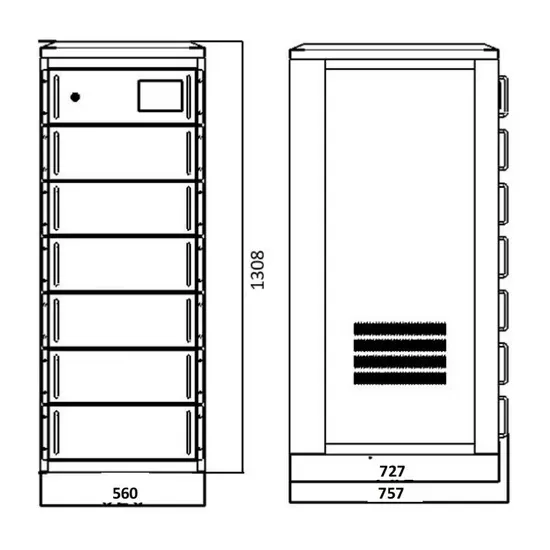

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.