Choosing the Right Lithium Ion Battery Cabinet: A Complete Guide

The right lithium ion battery cabinet is a vital investment for any business using rechargeable power systems. It protects against fire, enhances compliance, and streamlines

Get a quote

Where can the battery system be installed? What are the

Must be at least 3 feet apart from each other and any windows, doors, or gas meters. That means, for one battery system, you must have 9 feet of total working space. For a two battery

Get a quote

Management and maintenance of base station

The setting value of the primary and secondary power-off of the switch power supply: It should be set according to the type of base station, the

Get a quote

Tower base station energy storage battery

According to the requirement of power backup and energy storage of tower communication base station, combined with the current situation of decommissioned power battery, this paper

Get a quote

What equipment does the base station energy storage cabinet

High temperatures can accelerate battery degradation, reducing their lifespan and performance. Active and passive cooling methods are utilized to maintain optimal operating

Get a quote

Understanding Backup Battery Requirements for

Telecom base stations require reliable backup power to ensure uninterrupted communication services. Selecting the right backup battery is

Get a quote

Voltage Settings for BLVD & LLVD in Batteries

Recommended Voltage Settings for BLVD and LLVD The primary and secondary power-off settings in base station DC power supply systems are mainly

Get a quote

Voltage Settings for BLVD & LLVD in Batteries

The primary and secondary power-off settings in base station DC power supply systems are mainly distinguished based on differences in battery discharge voltage.

Get a quote

Outdoor Cabinets

The battery cabinet for base station is a special cabinet to provide uninterrupted power supply for communication base stations and related equipment, which can be placed with various types

Get a quote

Understanding Backup Battery Requirements for Telecom Base Stations

Telecom base stations require reliable backup power to ensure uninterrupted communication services. Selecting the right backup battery is crucial for network stability and

Get a quote

Installation and hardware | Base Help Center

What''s the lifespan of the Base battery? What hardware does Base use? Do you have spec sheets for the system? What is the temperature range of the battery? Why does Base request

Get a quote

Cooling for Mobile Base Stations and Cell Towers

BackgroundUnattended base stations require an intelligent cooling system because of the strain they are exposed to. The sensitive telecom equipment is

Get a quote

Custom Power Supply Cabinets | Riteoptic

Riteoptic provides custom-made, durable base station racks and cabinets for specific business requirements. Our base station cabinets can directly power

Get a quote

Battery Cabinet

Install the Battery Cabinet following local building requirements and applicable codes. Plan the location of the Battery Cabinet site ahead of time, taking into consideration the requirements

Get a quote

What equipment does the base station energy storage

1. The equipment utilized in the base station energy storage cabinet comprises multiple essential components, which include: batteries,

Get a quote

Base station energy storage battery requirements

This article provides a comprehensive guide on battery storage power station (also known as energy storage power stations). These facilities play a crucial role in modern power grids by

Get a quote

Voltage Settings for BLVD & LLVD in Batteries

The primary and secondary power-off settings in base station DC power supply systems are mainly distinguished based on differences in battery discharge

Get a quote

LLVD and BLVD in Base Station Power Cabinets

IntroductionIn modern communication networks, base stations, as core infrastructure, are crucial for stable operation. The base station power cabinet is a key equipment ensuring continuous

Get a quote

What equipment does the base station energy storage

High temperatures can accelerate battery degradation, reducing their lifespan and performance. Active and passive cooling methods are

Get a quote

Essential Requirements for Placing Energy Storage Batteries: A

The secret often lies in how and where you place those battery units. Whether you''re setting up a home solar system or managing a commercial energy park, understanding

Get a quote

LLVD and BLVD in Base Station Power Cabinets

Conclusie As two important protection mechanisms in base station power cabinets, LLVD and BLVD play a crucial role in ensuring the stable operation of base station equipment, extending

Get a quote

LBI-38636F

To minimize shock hazard, the station equipment cabinet must be connected to an electrical ground. The equipment supplied is equipped with a three-conductor AC power cord. The

Get a quote

5 FAQs about [Base station power cabinet battery setting requirements]

What are primary and secondary power-off settings in base station DC power supply systems?

The primary and secondary power-off settings in base station DC power supply systems are mainly distinguished based on differences in battery discharge voltage.

What are the minimum clearance requirements for a base station?

Minimum clearances must be maintained between the cabinets and surrounding building parts/cabinet to accommodate the installation and maintenance of the base station. The following constraints must be considered for cabinet clearances:

Where should a battery cabinet be installed?

The battery cabinet must be installed adjacent to the power cabinet. The following diagram shows the equipment layout for a typical new indoor Macrocell site. Notes: The cabinets may be placed with zero clearance to the rear wall. The cabinets may be placed with zero clearance to the side wall, however some clearance is recommended.

What happens when a battery voltage reaches a preset value?

When the battery voltage reaches a preset value (usually higher than the cut-off voltage), the system first disconnects non-critical loads, retaining power for critical loads. As the voltage continues to drop to the cut-off voltage, all loads are disconnected to protect the battery.

What is the minimum space between ezbfi frame and UMTS macrocell cabinet?

Minimum space between the EZBFi frame and the adjacent cabinet or frame is 57 mm (2.24 in.) (if the edge of the template is cut at the dotted line). The following diagram shows the clearance requirements for the indoor UMTS Macrocell cabinet from the top of the cabinet to the cable rack and from the top of the cable rack to the ceiling.

Guess what you want to know

-

Communication network cabinet base station power lithium battery

Communication network cabinet base station power lithium battery

-

Solomon Islands new energy battery cabinet base station power generation

Solomon Islands new energy battery cabinet base station power generation

-

Battery cabinet installation ESS power base station

Battery cabinet installation ESS power base station

-

Moisture-proof battery cabinet base station power generation

Moisture-proof battery cabinet base station power generation

-

Telecom site with battery cabinet base station power

Telecom site with battery cabinet base station power

-

Battery cabinet base station power board

Battery cabinet base station power board

-

Base station lithium battery cabinet power

Base station lithium battery cabinet power

-

Afghanistan communication base station flow battery photovoltaic power generation

Afghanistan communication base station flow battery photovoltaic power generation

-

Hungary photovoltaic energy storage cabinet battery factory base station

Hungary photovoltaic energy storage cabinet battery factory base station

-

Price trend of outdoor communication battery cabinet base station in Norway

Price trend of outdoor communication battery cabinet base station in Norway

Industrial & Commercial Energy Storage Market Growth

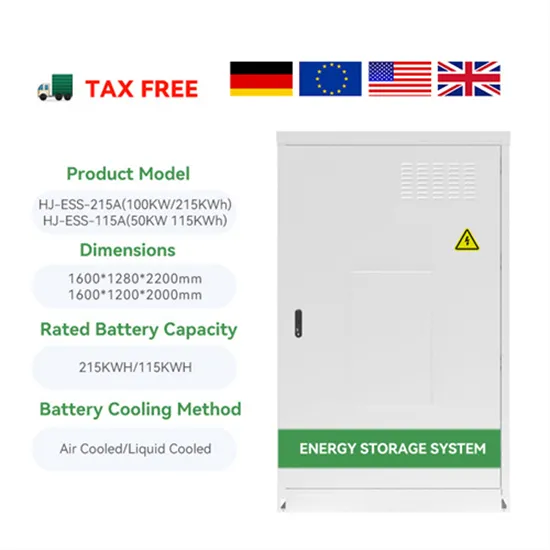

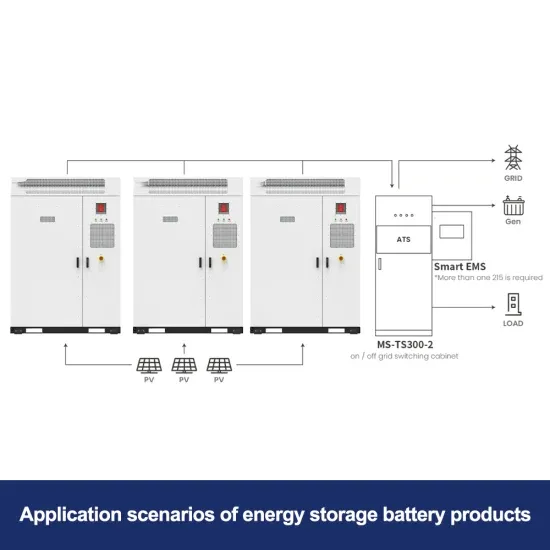

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.