THERMAL MANAGEMENT OF TELECOM ENCLOSURES

Efficiency: OSP cabinets and their temperature control systems invariably need standby batteries to ensure continuity of service in the event of a mains supply outage.

Get a quote

How does the energy storage battery cabinet dissipate heat?

Every battery cabinet ideally operates under established thermal management protocols designed to prevent overheating and maintain performance. These protocols

Get a quote

Thermal Management in Battery Systems Explained

This article explores how a thermal management system functions inside modern battery systems, particularly in industrial and commercial energy storage

Get a quote

Battery Thermal Management System Explained: Key To Battery

This article will discuss the basic concepts of the battery thermal management system, its main components, types, challenges, and solutions related to BTMS.

Get a quote

Battery Thermal Management

In this blog, we will explore the concept of battery thermal management and how it impacts the efficiency and safety of battery-operated systems. The Battery Thermal

Get a quote

Eaton s lithium-ion UPS battery Q&A

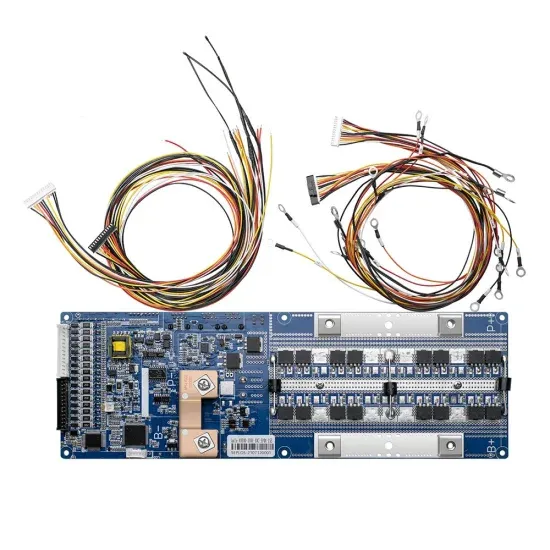

The battery management system (BMS) is one component which ensures the safe operation of the battery, by monitoring temperature, voltage balance, etc., and it has the ability to

Get a quote

The Ultimate Guide to Energy Storage Temperature Control Box:

If you''re managing solar farms, EV charging stations, or even just a home battery system, you''ve probably faced this headache: batteries that underperform in extreme heat or

Get a quote

Battery Management System (BMS) for Efficiency and Safety

What Is a Battery Management System (BMS)? A Battery Management System (BMS) is an electronic system designed to monitor, regulate, and protect rechargeable

Get a quote

What Are Battery Rack Cabinets and Why Are They Essential?

Battery rack cabinets are secure, organized, and often climate-controlled enclosures designed to safely store, protect, and charge multiple batteries, especially lithium

Get a quote

How to Optimize Thermal Management for Battery Energy Storage Systems

Optimize thermal management for battery energy storage systems in 2025 with AI, liquid cooling, and PCMs to enhance safety, efficiency, and lifespan.

Get a quote

Power and Control Applications for Thermal Management

Continuous operation of the thermal management system is critical to ensuring a safe operating tem-perature for the battery energy storage system. ABB''s control and power protection

Get a quote

The Complete Guide to Battery Thermal Management System

This is a guide to understanding what a battery thermal management system entails and why it''s critical for the latest applications.

Get a quote

Guide to Battery Cabinets for Lithium-Ion Batteries: 6

FAQs What is thermal runaway in lithium-ion batteries? Thermal runaway is a chain reaction where a battery generates heat, causing it to

Get a quote

Power and Control Applications for Thermal Management

Why do you need Control and Power Protection for your Thermal Management System? Continuous operation of the thermal management system is critical to ensuring a safe

Get a quote

SmartGen HBMS100 Energy storage Battery cabinet

HBMS100 Energy storage Battery cabinet is a battery management system with cell series topology, which can realize the protection of over charge/discharge

Get a quote

Battery Thermal Management System Explained: Key

This article will discuss the basic concepts of the battery thermal management system, its main components, types, challenges, and solutions

Get a quote

How to Keep Battery Storage Cabinets Safe

Key Takeaways Keep the temperature steady to stop batteries from overheating. Use tools and sensors to check heat levels. Pick good-quality batteries that follow safety rules.

Get a quote

What Is the Battery Capacity of Tesla Model Y

Professional tip: In subzero climates, keep the car plugged in whenever possible – the system will use wall power rather than battery energy for temperature management.

Get a quote

Thermal Management in Battery Systems Explained-Pknergypower

This article explores how a thermal management system functions inside modern battery systems, particularly in industrial and commercial energy storage applications.

Get a quote

How to Optimize Thermal Management for Battery Energy

Optimize thermal management for battery energy storage systems in 2025 with AI, liquid cooling, and PCMs to enhance safety, efficiency, and lifespan.

Get a quote

How to Manage the Temperature of a Lithium Battery Bank:

As we''ve found, managing the temperature limitations of lithium technology with thoughtful solutions enables system owners to utilize them at their full potential and in all sorts

Get a quote

Lithium-Ion Battery Charging Safety Cabinet

Justrite''s Lithium-Ion battery Charging Safety Cabinet is engineered to charge and store lithium batteries safely. Made with a proprietary 9-layer ChargeGuard™ system that helps minimize

Get a quote

215 kWh LFP Air Cooled Battery System | HISbatt

Our 3-level battery management system (BMS) guarantees safe operation by continuously monitoring all critical parameters at three distinct levels: the cell

Get a quote

A review of battery thermal management systems using liquid

The lithium-ion battery has strict requirements for operating temperature, so the battery thermal management systems (BTMS) play an important role. Liquid cooling is typically

Get a quote

6 FAQs about [How to use the battery cabinet temperature management system]

Why is thermal management important for a battery energy storage system?

Continuous operation of the thermal management system is critical to ensuring a safe operating tem-perature for the battery energy storage system. ABB’s control and power protection products help to reduce downtime and support continuity of ser-vice in any condition.

How to improve battery thermal management system performance?

The battery thermal management system performance can generally disrupted if it’s located in an area with excessively high or low temperatures. Solution: Add a heating system (PTC heater) and thermal insulation when extreme temperatures occur.

What is a battery thermal management system?

A battery thermal management system (BTMS) is a component in the creation of electric vehicles (EVs) and other energy storage systems that rely on rechargeable batteries. Its main role is to maintain the temperatures for batteries ensuring their battery safety, efficiency and lifespan.

What is a battery temperature sensor?

Temperature Sensor: Useful for monitoring the thermal condition of battery cells in real time. The data obtained from this sensor serve as the primary input used by the battery thermal management system control center to determine when and how the cooling or heating system should activated.

What happens if you don't have a battery thermal management system?

Without a battery thermal management system, the battery may experience a sudden increase in excess temperature during the charging and usage process.

Why is thermal control important for lithium battery energy storage systems?

Introduction As lithium battery energy storage systems (BESS) become increasingly powerful and compact, managing heat generation has emerged as a critical challenge. Without effective thermal control, systems risk performance degradation, shortened lifespan, and, in worst cases, thermal runaway.

Guess what you want to know

-

How big an outdoor battery cabinet should I use for 60v 58a

How big an outdoor battery cabinet should I use for 60v 58a

-

How to use the liquid-cooled energy storage smart battery cabinet

How to use the liquid-cooled energy storage smart battery cabinet

-

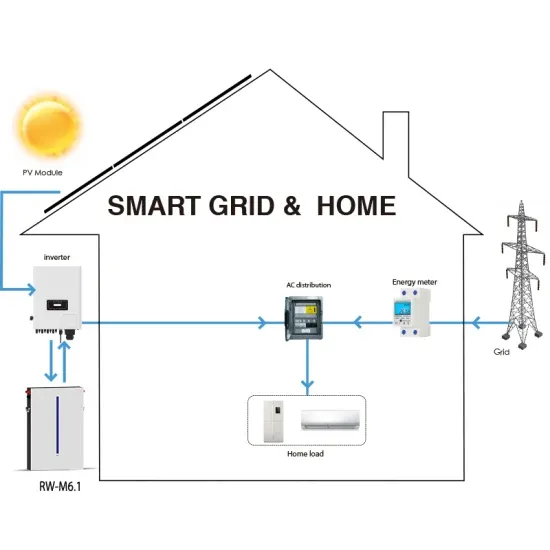

How to use electricity in photovoltaic backup battery cabinet

How to use electricity in photovoltaic backup battery cabinet

-

How many batteries are in a micro-module battery cabinet

How many batteries are in a micro-module battery cabinet

-

How many battery packs are in the battery cabinet

How many battery packs are in the battery cabinet

-

Battery cabinet thermal management technology

Battery cabinet thermal management technology

-

How much watts should I buy for an outdoor battery cabinet

How much watts should I buy for an outdoor battery cabinet

-

How much current does a 9v battery in an energy storage cabinet have in amperes

How much current does a 9v battery in an energy storage cabinet have in amperes

-

Battery cabinet maximum temperature 100KWh

Battery cabinet maximum temperature 100KWh

-

How to group batteries in a battery cabinet

How to group batteries in a battery cabinet

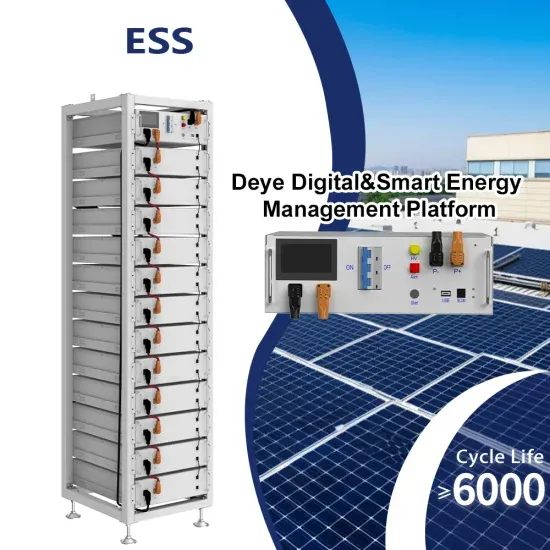

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.